6 Oz Staple Fiber Needle Punched Geotextile/Non-Woven Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | ROLLED IN PLASTIC BAG |

| Delivery Detail: | 3-5 DAYS |

Specifications

it prevents the bank from being washed out ,protects the bank and the bottom prevents the water and soil from being washed away.

Application of geotextiles

Filtration

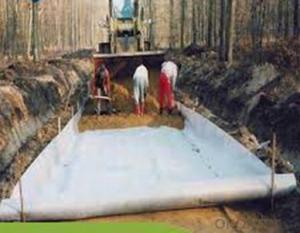

Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different

granule pathway from the groundsill or other buildings.

Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

Protection

1.Product introduction of geotextile:

1.Nonwoven geotextiles are multi-purpose fabrics that are felt-like in appearance.

2.Nonwoven Geotextiles are available in varying strengths and thicknesses to ensure appropriate material 3.selection for your project. Custom roll sizes are also available.

4.Nonwoven geotextiles have a wide range of applications in civil environmental engineering and construction projects.

2.Its usage of geotextile:

1 Filtration of soils in drainage applications by retaining soil particles while allowing for the free flow of water

2 Separation and stabilization in road and railway construction

3 Prevention of soil movement in erosion control measures

4 Cushioning and protection in many containment projects

FAQ:

♦ Payment terms: by T/T or L/C |

♦ MOQ:2000 SQM |

♦ If you are interested in our products ,pls advice me the technical index,product weight etc,the more information the better..... |

- Q: How do geotextiles improve the performance of geotubes?

- Geotextiles improve the performance of geotubes by providing additional reinforcement and stability. They act as a filtration layer, preventing soil erosion and allowing water to pass through while retaining fine particles. Geotextiles also enhance the strength and durability of geotubes by distributing loads evenly and reducing the risk of punctures or tears.

- Q: Highway on the highway geotextile laying program who has ah?

- According to your actual project, the Hongxiang Expressway geotextile can provide the overall solution. Hongxiang new material solution

- Q: What are the factors to consider when selecting geotextiles for landfill applications?

- When selecting geotextiles for landfill applications, there are several factors that need to be considered. These include the strength and durability of the geotextile, its filtration and drainage capabilities, chemical resistance, and its ability to withstand long-term exposure to environmental conditions such as moisture and ultraviolet radiation. Additionally, factors such as cost, availability, and compliance with regulatory requirements should also be taken into account.

- Q: What are the factors to consider when selecting geotextiles for coastal protection projects?

- When selecting geotextiles for coastal protection projects, there are several factors to consider. Firstly, the type and quality of the geotextile material is crucial. It should be durable, resistant to UV radiation, and capable of withstanding the harsh coastal environment, including exposure to saltwater and strong waves. Secondly, the intended function of the geotextile should be taken into account. Different geotextiles offer varying levels of erosion control, filtration, and stabilization. Therefore, the specific needs of the coastal protection project, such as preventing beach erosion or stabilizing coastal structures, should be considered. Thirdly, the site conditions and project requirements play a significant role. Factors like wave energy, sediment characteristics, and slope stability need to be assessed to determine the appropriate geotextile specifications. Furthermore, the installation and maintenance requirements should be evaluated. Geotextiles that are easy to install and require minimal maintenance are often preferred, as they can save time and costs during the project's lifespan. Lastly, the cost-effectiveness and longevity of the geotextile should be taken into consideration. It is essential to balance the initial cost of the geotextile with its expected lifespan and performance to ensure a sustainable and economical solution for coastal protection.

- Q: What are the different geotextile testing parameters?

- There are several different geotextile testing parameters that are used to evaluate the performance and quality of geotextiles. Some of the common parameters include tensile strength, puncture resistance, tear strength, permeability, apparent opening size, and UV resistance. These tests help determine the suitability of geotextiles for specific applications and ensure their durability and effectiveness in various geotechnical and civil engineering projects.

- Q: What is the specific use of geotextile construction site? How much is it used?

- From the reinforcement, the role of filtration, I am specializing in the production of geotechnical materials

- Q: How are geotextiles tested for filtration efficiency?

- Geotextiles are tested for filtration efficiency through standardized laboratory tests that involve measuring the flow rate of liquid or gas through the textile material. These tests evaluate the ability of geotextiles to retain particles while allowing water or air to pass through, helping determine their filtration efficiency.

- Q: What are the physical properties of geotextiles?

- Geotextiles are synthetic materials that possess various physical properties. These properties include high tensile strength, which allows them to withstand heavy loads, excellent flexibility, which enables them to conform to uneven surfaces, and resistance to biological degradation, ensuring their long-term durability. Geotextiles also exhibit good permeability, allowing water to pass through while retaining soil particles, and have high resistance to UV radiation, enabling them to withstand exposure to sunlight. Additionally, they are lightweight, easily transportable, and easy to handle and install, making them a popular choice in various civil engineering and construction applications.

- Q: Can geotextiles be used for erosion control in coastal dunes?

- Yes, geotextiles can be used for erosion control in coastal dunes. Geotextiles are often used as an erosion control measure in coastal areas to stabilize the soil and prevent erosion caused by wind and water. They can be installed on the dune slopes to prevent sand movement and promote vegetation growth, thereby maintaining the integrity of the dune system and protecting it from erosion.

- Q: Are geotextiles resistant to fungal growth?

- Yes, geotextiles are generally resistant to fungal growth. They are designed to be durable and have low organic content, which makes them less susceptible to fungal colonization. Additionally, geotextiles are often treated with fungicides during manufacturing to provide further protection against fungal growth. However, the resistance may vary depending on the specific type and quality of geotextile used.

Send your message to us

6 Oz Staple Fiber Needle Punched Geotextile/Non-Woven Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords