Geotextile Nz PP Non-Woven Geotextile Fabric for Railway from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

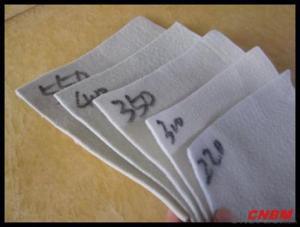

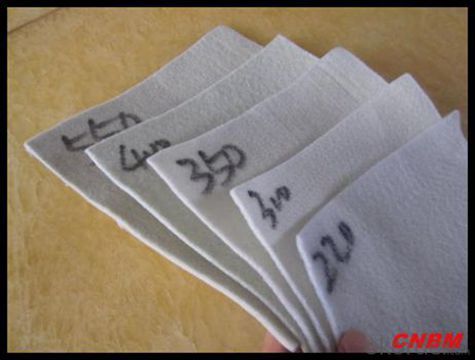

Specification

We also can design special geotextiles according customer’s requests

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

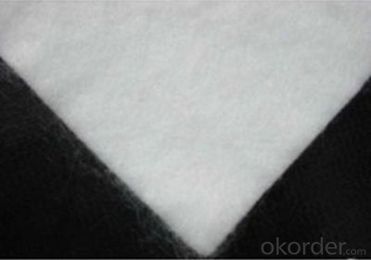

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What type of geotextile is used for soccer field

- Generally with permeable geotextile, 200g300g can be

- Q: How are geotextiles affected by moisture content?

- Geotextiles can be affected by moisture content in several ways. When exposed to excessive moisture, geotextiles can lose their strength and integrity, leading to reduced performance and functionality. Excessive moisture can also cause geotextiles to become clogged or blocked, affecting their ability to drain water and maintain their permeability. Additionally, moisture content can impact the durability and lifespan of geotextiles, as it can contribute to the growth of microorganisms that can degrade the material. Therefore, it is crucial to consider moisture management when using geotextiles in various applications.

- Q: 400g / m2 two cloth a layer of water permeable geotextile technical requirements

- Two cloth a film will not be permeable, the composite film index breaking strength 5kn top broken 1.1kn tear 0.15kn peel 6n / cm or substrate fracture without stripping, the current 2008 standard weight has not been required, the original standard For not less than 360 grams

- Q: Woven geotextile is not considered a spinning geotextile

- Woven geotextile is made of textile technology is a spinning geotextile.

- Q: what do you mean nonwoven geotextiles ???

- please refer the folowing url to know all the details about non woven geo textiles

- Q: How do geotextiles help with soil stabilization in construction sites?

- Geotextiles help with soil stabilization in construction sites by providing reinforcement and separation between different soil layers. They act as a barrier, preventing the mixing of different soil layers, which helps maintain the stability and strength of the soil. Additionally, geotextiles distribute the load evenly across the construction site, reducing the potential for soil erosion and settling.

- Q: What is the place of attention for the laying of geotextiles?

- (1) the use of the use of buried type: cover the thickness should not be less than 30cm (2) refurbishment system should be: cushion, impermeable layer, transition layer, protective layer composition. (3) soil to be solid, to avoid uneven subsidence, cracks, anti-seepage within the turf, root to clear. And the surface of the membrane with a small particle size of sand or clay as a protective layer. (4) laying the geomembrane do not pull too tight, both ends of the soil into the corrugated part of the soil is better, especially with the rigid material anchoring, should leave a certain amount of expansion and contraction. (5) construction, should avoid stones,

- Q: Are geotextiles environmentally friendly?

- Yes, geotextiles can be considered environmentally friendly. Geotextiles are designed to have minimal impact on the environment and can be made from recycled materials. They can help with erosion control, soil stabilization, and filtration, reducing the need for harmful chemicals or excessive soil excavation. Additionally, geotextiles are often biodegradable or can be recycled at the end of their lifespan, further contributing to their environmental friendliness.

- Q: Pool with geomembrane but not long enough to stick to the pool side

- Should be geomembrane professional welding machine welding, not long enough, then do not seepage effect, I am specializing in the production of geotextile geomembrane and other materials, wish smooth

Send your message to us

Geotextile Nz PP Non-Woven Geotextile Fabric for Railway from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords