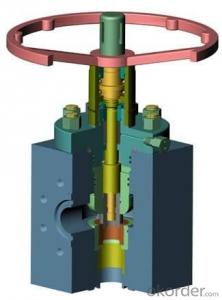

New API 6A Manual Non-rising Stem Flat Gate Valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 unit

- Supply Capability:

- 1900 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | High Pressure |

| Power: | Manual | Material: | alloy | Temperature of Media: | Medium Temperature |

| Media: | Oil | Port Size: | 2-1/16 through7 1/16 | Place of Origin: | China (Mainland) |

| Model Number: | OKORDER | Brand Name: | OKORDER | WARRENTY: | ONE YEAR |

Packaging & Delivery

| Packaging Detail: | standard package |

| Delivery Detail: | 15 days |

Specifications

New API 6A Manual Non-rising Stem Flat Gate Valve

1.API 6A ISO9001 Certification

2. professional designers

3.Top quality

1) Wellhead and Christmas tree (casing/tubing head, casing /tubing hangers, crosses ,flange adaptor. fracturing equipment , tree cap etc)

2) Valve (FC/FLS gate valve, expanding gate valve, Slab gate valve ,chock valve, check valve)

3) Bop(Annular/Ram BOP)

slab gate valve is a bi-directional, with a preferred sealing side valve for application on wellheads, production trees and manifolds with working pressure at and below 5000 psi.

1 API 6A latest edition

2 Forged bonnet

3 Low operation torque

4 O-ring body/bonnet seal

5 Lubrication fittings for easy maintenance

6 Manual or actuated operation

7 Simple design assures low cost

8 Flanged or screwed outlets

Non-rising stem type flat gate valve

- Q: Need some info. Ok, four valves per cylinder is better than two valves per cylinder. Fine, why did Ford REVERT to only 3 valves (my guess is to save cost SOHC)? Audi and VW are using five valves per cylinder on some cars, does this offer any advantage over a four valve engine? Maserati even experimented with a six valve per cylinder!!!! (see link) http://www.maserati-alfieri .uk/alfieri26.htm but abandoned it (my guess is cost again?) Why are we stuck at four valves or would more valves actually render more horsepower? Pop some ideas best answer to reasonable answer...

- Multi Valve

- Q: It started leaking slowly so I opened the release valve for about 20 secs than closed it back to see if that would help, but now it leaks even more. So I had to shut off the water that's coming into the water heater and know I can't use the hot water in my house. Can someone help me please!!!!

- i find it better the telfon paste instead of the tape,use paste and not leaks,should find it in the plumming supplies

- Q: HowdyWas taking apart a screw down NR valve and screw lift valve and noticed the spindles were made out of different materials. Brass and Steel.I am aware that brass is non corrosive but why use steel in the other valve? Is it due to their operation, do they come or not come in contact with fluids? Is one cheaper than the other?The screw lift globe valve had a steel spindle and the screw down nr glove valve had a brass spindle.Also, if anyone knows what materials are used in the valve lid and seat are made of.Any ideas?Cheers

- *In steam service , steam flashing is one of the factor which erode the spindle ( say valve stem) *The stem serves as a connector from the actuator to the inside of the valve and transmits this actuation force. Stems are either smooth for actuator controlled valves or threaded for manual valves. The smooth stems are surrounded by packing material to prevent leaking material from the valve. This packing is a wearable material and will have to be replaced during maintenance. With a smooth stem the ends are threaded to allow connection to the plug and the actuator. The stem must not only withstand a large amount of compression force during valve closure, but also have high tensile strength during valve opening. In addition, the stem must be very straight, or have low run out, in order to ensure good valve closure. This minimum run out also minimizes wear of the packing contained in the bonnet, which provides the seal against leakage. The stem may be provided with a shroud over the packing nut to prevent foreign bodies entering the packing material, which would accelerate wear. Disc material: Cast Iron or Ductile Iron Disc Aluminum-bronze Disc Stainless Steel Disc Nickel-plated Ductile Iron Lid material: engineering plastics, Cast Iron. Seat material[hard/soft]: Seats can be integral to the valve body, that is hard metal or plastic. *Hard seat: Hardened steel,Cast Iron,EN-52 forging steel Valve Seats are made from Chrome Alloy Steel which has a high wear resistance at high temperature. Nearly all metal seated valves leak, even though some leaks are extremely small. *Soft seats can be fitted to the valve body and made of materials such as PTFE or various elastomers such as NBR, EPDM, FKM. Each of these soft materials is limited by temperature (rough maximum temperatures are listed below) NBR 80 °C EPDM 120 °C FKM 170 °C PTFE 200 °C

- Q: i am wanting to know if there is a diagram of the engine or at least if you have to remove the intake manifold to get to the egr valve.

- the accord is one of the best engineered cars that honda has ever produced and if the one you are looking at has a sunroof and leather it is a ex-L model witch is the top of the line model the milage on it is good and the price is as well your are getting a good deal but there are two things you need to know the automatic trannys that came in the v6 accord have alot of problems but dont let that worry you the trannys in the v6 accords from 98 to 02 the 6th gen model normally go out between 100000 and 110000 miles but honda extended the warranty on them to cover this problem so you wont have to pay for it that right there is a great bonus because even though the tranny will go out honda will cover the cost and you get a brand new tranny that is good for another 100000 miles now the second thing is the timing belt is recomended to be replaced between 90000 and 110000 miles but with only 76000 miles on it you have a ways to go before you have to worry about that I myself have an 02 accord 2dr ex-L 4cyl. and i love it it had 68000 miles on it when i got it and now has 80000 and i have only had it for 11 months but i drive my car alot and i drive it even harder i dont think i have ever shifted to the next gear untill it redlined witch i know is really bad for the car but even with as hard as i drive mine i have never had one problem with it well except for the damage i did the under carraige from having it lowered 2 and a half inch when i bottomed out going 127 on the interstate haha good times but yes you are geeting a good deal and if you get this car you will love it

- Q: My pressure reducing valve has gone bad. This looks like a pretty simple change. My question is do i loosen the union nut first (after draining water line), then loosen the whole valve??? Then reverse to install??? Any info would be great....

- some reducing valves are adjustable. if this one has a locknut witha screw on good thats probable the explanation for loss of psi. via turning the screw in you advance the psi. if it has no screw examine the score on it. you like 60-a hundred psi variety. if nonetheless no answer do away with the valve and see if sturdy rigidity comes out of the meter. its a fashion of removal and a splash attempt. it particularly is the meter. you may troubleshoot its one or the different.

- Q: Or could you put a blow off valve on a supercharger?

- The supercharger will always have the whine sound at idle and normally disappears the higher the RPM is. Now most supercharger systems do come with a by-pass valve which functions the same as a blow off valve. They both are used to prevent surging of the compressor when your throttle body closes. Now the sound is slightly different. With a turbo it is more aggressive where you normally hear the high pitch whistle sound. With the by pass valve it is similar however it is not as high pitched. However you still can here the whoosh sound when you change gears or let off the gas. Now this whoosh sound is only present on superchargers which are equipped with a by pass valve AND the valve is being vented into the atmosphere. Some by pass valve have to be vent back into the air intake assembly which causes the sound not to be there. Normally cars that have the by pass valve after the mass air meter HAVE to be re routed back into the system, so you will not get that noise. And for those applications that have the by pass valve before the mass air normally vents into the atmosphere allowing you to hear that whoose noise. So to make this simple....the blow off valve noise can be heard depending on which type of application you have. And btw...YES you can adapt a blow off valve onto curtain superchargers however normally you will need one with a stiff spring to work. But, I would recommend running a by pass valve instead of a blow off valve for they are designed for superchargers because they are vacuumed operated.

- Q: i have a 1986 Ford Mustang 3.8L V6 automatic. i need to change to valve cover gaskets but im not sure if i can do it. what do i need to do? and do i need to ad something else other than new gaskets? thanks

- least confusing to purely do away with the valve hide thoroughly and then there could be adequate of the broken bolt left to get a pair of vice grips on it and unscrew it out, pass to factors shop and get a clean bolt and a clean valve hide gasket and reinstall.in case you tension the motor vehicle the way it incredibly is it may leak slightly oil around the broken bolt.

- Q: And' the valve leaks......Can the valve be unscrewed from the tank for replacement? Or can the valve be serviced with a new gasket perhaps?

- If it is a regular brass valve, you will have to drain the tank first, then replace the washer in the valve with one rated to be used for hot water. You replace the washer just as in any valve by removing the bonnet and stem. there you will see the washer. You may want to clean the area of any calcium carbonate that may had developed on the seat before putting it back together. If you decide to replace the valve, it is a 3/4 inch male NPT hose bib valve rated for hot water service. Personally, I've always thought that if I ever had to change one of those valves, that I would replace ti with a good ball valve that had a threaded hose end screwed into the discharge end for better drain flow. The whimpy valves that they put on water heaters is pathetic! If you use your favorite search engine and just search for water heater drain valve, you will find all kinds of cool replacement valves!

- Q: im trying to turn on my sprinklers from the valve manually,but doesn't seem to work, the valve it's an antisiphon rainbird valve with two little knobs, I know that one is the bleeder and the other the pressure control, or something like that, and the solenoid has the on and off arrows on it, but i can't do it anyways,they come on automatically right on time ,it's just the manual thing that i can't do, please help me,i really need it

- This Site Might Help You. RE: how do I turn on a rainbird valve manually? im trying to turn on my sprinklers from the valve manually,but doesn't seem to work, the valve it's an antisiphon rainbird valve with two little knobs, I know that one is the bleeder and the other the pressure control, or something like that, and the solenoid has the on and off arrows on...

- Q: i got a filler neck for my dodge dakota and was wondering how to put it on. can anyone send me a link or help me. and also what does my EGR valve look like and i cant seem to find a new one not even at the dealer. i was told to clean it how do i do this. can someone send me a link or pic what it look like. thanks

- The VECI decal map under your hodd will show you EXACTLY where your EGR valve is. You may need a magnifying glass. The valve can be removed and cleaned with Gum-out or foaming cleaner (amsoil). When you are done, re-install the valve. While you are getting ambitious, clean your throttle body and plate, and the IDLE AIR CONTROL VALVE. A dirty IAC is the most prominant reason for the EGR valve to clog up. Running Gum-out through your intake system will clean out your O2 sensors, as well. Good luck!!

Send your message to us

New API 6A Manual Non-rising Stem Flat Gate Valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 unit

- Supply Capability:

- 1900 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords