Geotextile Filter Layer Needle Punch Geotextile for Railway from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

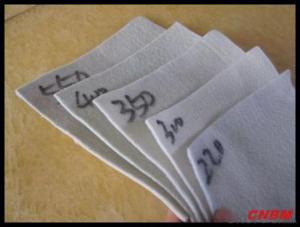

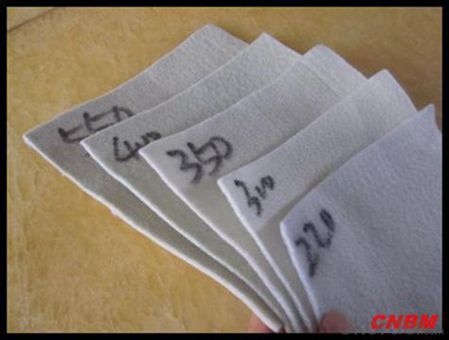

1.Unit weight 100g/sqm,150g/sqm,200g/sqm,250g/sqm,300g/sqm,350g/sqm,400g/sqm,450g/sqm,500g/sqm,600g/sqm,800g/sqm

2.Width

1m-8m

3.Length:

Per clients' request

Application of geotextile

Filtration

It can be the filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different

granule pathway from the groundsill or other buildings.

Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

Protection

It prevents the bank from being washed out, protects the bank and the

bottom, prevents the water and soil from being washed away.

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the different geotextile installation techniques for landfill applications?

- There are several geotextile installation techniques used for landfill applications, including direct burial, slope installation, and liner attachment methods. Direct burial involves placing the geotextile directly on the ground or compacted soil, with subsequent layers of soil or waste material placed on top. Slope installation involves installing the geotextile on a slope, often using anchoring systems to secure it in place. Liner attachment methods involve attaching the geotextile to the liner system, which may include geomembranes, geocomposites, or other liner materials. These techniques are used to enhance the performance and stability of landfills by providing separation, filtration, and drainage capabilities.

- Q: Geosynthetics direct shear instrument reference standards which

- Geosynthetics Direct shear test The abrasive characteristics of the sand / geotextile interface were measured by direct shear test of the standard sand / geotextile contact surface. Test Specimens: 1. Tile the specimen on a rigid horizontal base located in the lower part of the shear box, with the front end of the specimen, and the test leads: ISO.1, GB / T.1, ASTM / D5321, JTGE50T1129, SL / T235-1999. Clamped in front of the shear zone, the sample and the base between the adhesive with adhesive, after bonding the sample should be flat, without folding and folding, the test sample and the base is not allowed between the relative slip; 2. Install the upper shear box: with the pre-quasi-quality standard sand filled with the upper shear box, the thickness of 50mm, sand thickness should be uniform, after the density of the density of 1750kg / m3; 3. Install the horizontal loader , And apply 50KPa to the sample with a reference weight of 50KPa normal pressure.

- Q: What is the consequence of the geotextile of the ground floor

- What are the consequences of what can not be finalized, the first roof of the waterproof layer and waterproof protective layer is very important, this is the first barrier, imagine, now many of the green plants are large trees, grow 10 years or even 20 years After the roots will be very developed, think about how the pine trees on the tenacious know their strength, coupled with long-term erosion by the water, the concrete layer will gradually lose its ideal performance, barrier layer and drainage board will certainly be better To protect the role and drainage. So to speak, long-term vision of the words must be solidly do every layer, only focus on economic interests and short-term effects, then, within a few years will not be any problem.

- Q: What are the standards and specifications for geotextiles?

- Geotextiles are specifically engineered fabrics used in civil engineering projects to enhance soil stability, filtration, drainage, and separation. The standards and specifications for geotextiles are established by various organizations, including the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards outline the testing methods and performance requirements for geotextiles in terms of their physical properties, strength, durability, and resistance to environmental factors. These standards ensure that geotextiles meet the necessary quality and performance criteria for their intended applications, promoting consistency and reliability in the construction industry.

- Q: How do geotextiles help with reinforcement of geogrids?

- Geotextiles help with the reinforcement of geogrids by providing a stable base and preventing soil erosion. They act as a separation layer between the geogrid and the soil, distributing the load evenly and increasing the overall strength and stability of the structure.

- Q: What kind of geotextile is used to repair the road?

- Geotextile in the application of the road: a slope care, specifications in the 250-350g / m2 its role has the following three points: 1. filter when the water from the fine soil into the coarse soil layer, the use of polyester staple fiber Acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand, small stone, etc., in order to maintain the stability of soil and water engineering. 2. Drain polyester staple fiber geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of excess liquid and gas efflux. 3. Protection of water flow on the soil erosion, the effective concentration of concentrated diffusion, transmission or decomposition, to prevent the soil by external forces and damage. Second, the foundation treatment, the main role is to strengthen. The use of polyester staple acupuncture geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve soil quality. Specifications not low 400g / m2. The main role is to use the polyester staple fiber geotextile with different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.) ) To isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. Specifications in the 150-400g / m2

- Q: The secondary lining of the tunnel to install the vertical ring to the blind tube hang the geotextile waterproof board generally used for how long

- See the progress of the project

- Q: Production of acupuncture carpets, geotextiles, warm flakes, paper blankets, air filter materials, the main raw material is what? why?

- Fiber, like eating bread must be the same with the face

- Q: How do geotextiles help with groundwater protection?

- Geotextiles help with groundwater protection by acting as a barrier that prevents the movement of contaminants and pollutants from entering the groundwater. They are designed to filter and separate soil particles, allowing water to pass through while trapping harmful substances. Additionally, geotextiles can also enhance the stability and permeability of soil, reducing the risk of erosion and promoting proper drainage, which further aids in protecting the quality and quantity of groundwater.

- Q: Waterproof geotextile in which the location of the culvert, what use

- Used in the top and side, lining the inside, mainly the role of waterproof to prevent water seepage. Huazhi geotechnical materials manufacturers need to answer for your needs

Send your message to us

Geotextile Filter Layer Needle Punch Geotextile for Railway from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords