Mirafi Woven Geotextile Needle Punched & Geotextile Non-Woven for Construction - CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Woven Geotextile is permeable fabrics which, when used in association with soil, have the ability to separate, filter, reinforce, protect or drain. We are a professional supplier of woven geotextile, and our products are of high protective and flexible.Also we always try to be dedicated in supplying the best qualitied product at the most reasonable price in order to build a long relationship with each other.

Product description Woven Polypropylene (Pp) Geotextile

Woven Geotextile is permeable fabrics which, when used in association with soil, have the ability to separate, filter, reinforce, protect or drain. We are a professional supplier of woven geotextile, and our products are of high protective and flexible.Also we always try to be dedicated in supplying the best qualitied product at the most reasonable price in order to build a long relationship with each other.

FAQ:

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

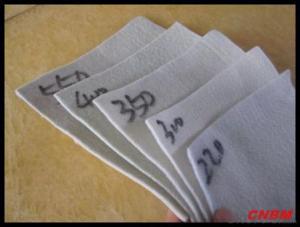

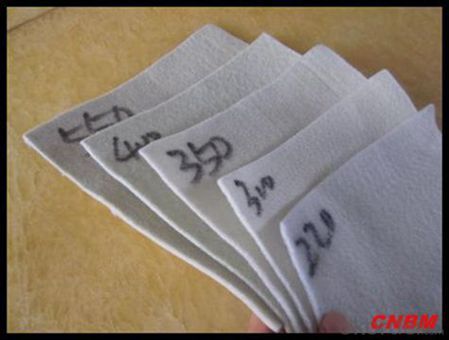

Photos:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in contaminated soil?

- Yes, geotextiles can be used in contaminated soil. Geotextiles are often used in contaminated soil remediation projects to provide separation, filtration, and reinforcement. They help to control the migration of contaminants, prevent soil erosion, and improve the stability of the soil. By effectively containing and treating the contaminants, geotextiles contribute to the overall success of soil remediation efforts.

- Q: How do geotextiles help with bridge abutment protection?

- Geotextiles help with bridge abutment protection by providing a stable and erosion-resistant layer between the soil and the abutment. They prevent soil movement, control water flow, and enhance the abutment's overall stability, reducing the risk of erosion and structural damage.

- Q: Mainly on the cement concrete laying asphalt overlay and deck pavement, a bit puzzled, sticky words and how to design more

- Can be set together, geotextile in the lower layer can play a good pull, the role of protection!

- Q: How do geotextiles assist in slope stabilization?

- Geotextiles assist in slope stabilization by providing reinforcement and erosion control. They are placed on the slope surface to distribute the stress and load more evenly, preventing soil erosion and slippage. Additionally, geotextiles help in promoting vegetation growth, further enhancing slope stability.

- Q: Contracted geotextile impermeable membrane laying artificial one square how much money

- Depending on where you look at the construction, the normal range of 2 to 4 yuan.

- Q: How do geotextiles help with reinforcement of geotextile bags?

- Geotextiles help with the reinforcement of geotextile bags by providing strength and stability to the bags. They act as a barrier and prevent the soil or other fill material from escaping through the pores of the bags. Additionally, the geotextiles distribute the weight of the fill material evenly, reducing the risk of bulging or bursting of the bags.

- Q: Geotextile 500 grams is what it means

- 500g per square meter of quality, I professional production geotextile geomembrane, wish smooth

- Q: How are geotextiles tested for filtration efficiency?

- Geotextiles are tested for filtration efficiency through standardized laboratory tests that involve measuring the flow rate of liquid or gas through the textile material. These tests evaluate the ability of geotextiles to retain particles while allowing water or air to pass through, helping determine their filtration efficiency.

- Q: How are geotextiles used in drainage systems?

- Geotextiles are commonly used in drainage systems to enhance their efficiency and longevity. These synthetic fabrics are placed in various parts of the system, such as around pipes or in trenches, to act as a filter and separator. By preventing the clogging of soil particles, geotextiles allow water to flow through while preventing the passage of fine particles. This helps maintain the system's hydraulic capacity and prevents blockages, ultimately improving the overall performance of the drainage system.

- Q: Thank you, great gods

- Polyester short wire, polyester filament, polypropylene geotextile, filament woven geotextile, and so on. I professional production geotextile geomembrane and other geotechnical materials, a professional construction of the welding team, wish smooth

Send your message to us

Mirafi Woven Geotextile Needle Punched & Geotextile Non-Woven for Construction - CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords