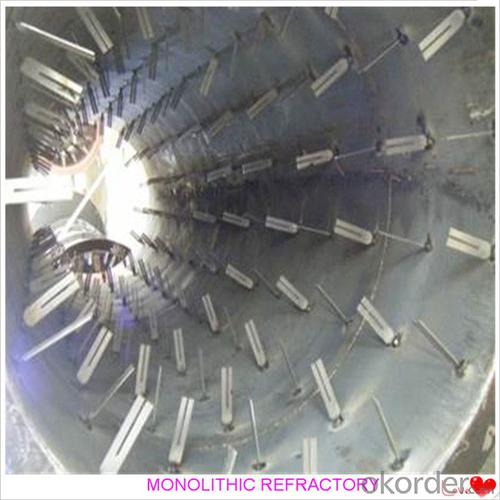

Monolithic Refractory Castable Refractory Castable For Iron and Steel Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Monolithic Refractory Castable Refractory Castable For Iron and Steel Industry

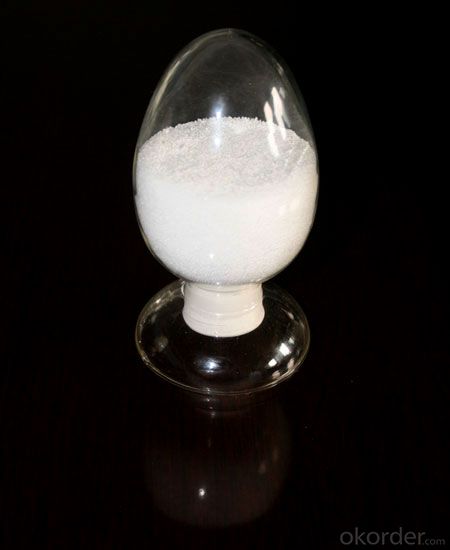

Product Description of Refractory Castable:

Refractory castable is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by the clients. The refractory castables are used high purity raw materials and additives as the main material, and made of under superfine powder adding technology.

Product Advantages of Refractory Castable:

The refractory castable has excellent structural stability and air tightness, and has high physical and chemical properties, also has a fine working ability.They should be used with the same material products.

Product Applications of Refractory Castable:

For feature of refractory castable, they have excellent abrasion resistance, thermal shock resistance, high-temperature resistance, anti-corrode and have high intensity.

Designed for refractory lining of blast furnace iron and slag runners, skimmers and soon

Refractory castable can be used in troughs of small and mid size BFs and in all positions of the troughs where fast tapping is required.

Product Specifications of Refractory Castable

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

Product Picture of Refractory Castable:

- Q: How are monolithic refractories installed and repaired in iron and steel plants?

- Monolithic refractories in iron and steel plants are typically installed through a process called gunning, where a specialized gunning machine is used to spray the refractory material onto the desired surface. The refractory material is mixed with water or a bonding agent to form a dense and durable lining. In terms of repairs, damaged or worn-out monolithic refractories are typically removed by mechanical means, such as jackhammers or pneumatic tools. The damaged area is then cleaned and prepared before new refractory material is applied using the gunning method. In some cases, patching materials may be used to repair smaller areas of damage. Overall, the installation and repair of monolithic refractories in iron and steel plants require skilled technicians and specialized equipment to ensure the optimum performance and longevity of the refractory lining.

- Q: How do monolithic refractories prevent thermal radiation in the iron and steel industry?

- Monolithic refractories play a crucial role in preventing thermal radiation in the iron and steel industry. Thermal radiation refers to the transfer of heat energy through electromagnetic waves, and it can be a significant challenge in this industry due to the high temperatures involved. Monolithic refractories, which are single-piece refractory materials, are designed to have excellent thermal insulation properties. They have low thermal conductivity, which means they are not good conductors of heat. This property allows them to act as a barrier against thermal radiation. When used in the iron and steel industry, monolithic refractories are typically applied as linings in furnaces, ladles, and other equipment that are exposed to extremely high temperatures. These linings serve as a protective layer, preventing the heat from escaping and reducing the amount of thermal radiation emitted. Additionally, monolithic refractories have high emissivity, which refers to their ability to absorb and re-emit thermal radiation. This property allows them to effectively capture and contain the heat within the equipment, minimizing the amount of radiation that escapes into the surroundings. By preventing thermal radiation, monolithic refractories help to maintain the desired temperatures within the iron and steel production process. This is crucial for achieving efficient and controlled operations, as well as ensuring the quality of the final products. Furthermore, the use of monolithic refractories in the iron and steel industry also contributes to energy savings. By reducing the heat loss through thermal radiation, less energy is required to maintain the desired temperatures, resulting in lower energy consumption and cost savings. In conclusion, monolithic refractories are essential in preventing thermal radiation in the iron and steel industry. Their excellent thermal insulation properties, low thermal conductivity, and high emissivity make them effective barriers against heat transfer through radiation. By minimizing heat loss and ensuring controlled temperatures, monolithic refractories contribute to efficient operations, high-quality products, and energy savings.

- Q: What are the different types of monolithic refractories used in the iron and steel industry?

- The iron and steel industry relies on various types of monolithic refractories for their exceptional thermal resistance, strength, and durability. These refractories are crucial in withstanding extreme temperatures and harsh conditions in a range of applications. Firstly, there are castables, which are precast refractory materials that form a slurry when mixed with water. This slurry is then poured or cast into molds. Castables are widely used in the iron and steel industry to line ladles, tundishes, and furnaces due to their high strength and resistance to thermal shock. Another type is ramming mass, which is used to line induction furnaces and melting units. It is composed of refractory aggregates, binders, and additives. Ramming mass is applied by ramming or tamping it into place, creating a dense lining capable of withstanding high temperatures and chemical attacks. Gunning mix is a refractory material applied using a pneumatic gunning machine. It is particularly useful for repairing or lining various areas of furnaces, especially during hot repairs. Gunning mix consists of refractory aggregates, binders, and additives that are sprayed onto the lining surface and then compacted. Plastic refractories, on the other hand, are mixtures of refractory aggregates and binders with high plasticity. They can be easily molded or shaped, making them ideal for repairing or patching refractory linings in the iron and steel industry. Plastic refractories are typically applied by hand or with a trowel and are suitable for both hot and cold applications. Lastly, refractory mortars are used for jointing or repairing refractory bricks or other monolithic refractories. They are composed of refractory powders, binders, and water. Mortars provide excellent adhesion between bricks or monolithic materials, ensuring a strong and durable lining in furnaces, ladles, and other high-temperature equipment. These various types of monolithic refractories are indispensable in the iron and steel industry. They provide reliable and long-lasting linings, ensuring efficient operations and minimizing downtime.

- Q: What are the key innovations in monolithic refractories for the iron and steel industry?

- Some key innovations in monolithic refractories for the iron and steel industry include the development of advanced materials such as low cement castables, gunning mixes, and shotcretes. These materials offer improved resistance to thermal shock, increased strength, and enhanced erosion resistance, thereby extending the service life of refractory linings in high-temperature environments. Additionally, the introduction of monolithic refractory installation techniques such as robotic application and advanced spraying technologies has improved efficiency and reduced downtime during maintenance and repair operations.

- Q: What are the recommended curing and drying procedures for monolithic refractories?

- The curing and drying procedures for monolithic refractories vary depending on the specific type and composition of the material. However, there are some general guidelines that can be followed. Curing involves allowing the refractory material to set and harden. This is achieved by subjecting the material to controlled temperature and humidity conditions. The purpose of curing is to develop the desired physical and chemical properties of the refractory, such as strength and resistance to thermal shock. Drying, on the other hand, involves removing moisture from the refractory material. This is important because moisture can cause cracking or spalling when exposed to high temperatures. Drying usually takes place after the curing process. The curing and drying procedures for monolithic refractories typically involve the following steps: 1. Preheating: Before applying the refractory material, it is necessary to preheat the surface where it will be applied. This prevents rapid moisture evaporation and ensures good adhesion of the refractory. 2. Mixing and application: The refractory material should be mixed according to the manufacturer's instructions and applied to the desired surface using appropriate techniques such as gunning, casting, or ramming. 3. Initial curing: After application, the refractory should be cured at a controlled temperature and humidity for a specific duration. This allows the material to set and strengthen. The curing temperature and duration may vary depending on the specific refractory material, but it is advisable to start with a lower temperature and gradually increase it. 4. Drying: Once the initial curing is complete, the refractory should be dried to eliminate any remaining moisture. This is done by gradually increasing the temperature in a controlled manner. The drying temperature and duration may vary depending on the specific refractory material, but it is important to avoid rapid temperature changes to prevent thermal stress and cracking. 5. Final curing: After drying, the refractory should be allowed to cool gradually to room temperature. This final curing step further enhances the strength and stability of the refractory. It is crucial to follow the manufacturer's guidelines and recommendations for the specific refractory material being used, as different materials may have different curing and drying requirements. Additionally, factors such as the size and shape of the refractory installation, as well as the surrounding environment, may also affect the curing and drying procedures. It is always advisable to consult with a refractory specialist or manufacturer to ensure the proper curing and drying procedures are followed for optimal performance and longevity of the monolithic refractories.

- Q: Can monolithic refractories be used for the lining of reheating furnaces and walking beam furnaces?

- Yes, monolithic refractories can be used for the lining of reheating furnaces and walking beam furnaces. Monolithic refractories are versatile and can be shaped to fit the specific requirements of these furnaces. They offer excellent thermal insulation, high temperature resistance, and durability, making them suitable for withstanding the extreme conditions within these furnaces. Additionally, monolithic refractories can be easily installed, repaired, and replaced, making them a practical choice for lining these types of furnaces.

- Q: What are the advantages of using low-moisture castables in the iron and steel industry?

- Low-moisture castables offer several advantages in the iron and steel industry. Firstly, they have a lower water content, which allows for faster and easier installation. This results in reduced downtime and increased productivity. Secondly, low-moisture castables have excellent strength and thermal shock resistance, making them highly durable in high-temperature applications. This helps to prolong the lifespan of refractory linings, saving on maintenance and replacement costs. Additionally, their low moisture content minimizes the risk of steam explosions during installation or curing. Lastly, these castables offer improved energy efficiency by reducing heat loss, resulting in lower fuel consumption and greenhouse gas emissions. Overall, the use of low-moisture castables in the iron and steel industry enhances operational efficiency, durability, and environmental sustainability.

- Q: What are the recommended curing times for monolithic refractories?

- The recommended curing times for monolithic refractories can vary depending on the specific type of refractory and its application. However, in general, it is important to follow the manufacturer's guidelines for curing times to ensure the proper setting and development of the refractory material. For conventional castable refractories, a typical curing time can range from 24 to 48 hours. During this period, it is essential to control the temperature and humidity conditions to allow for the hydration and hardening of the castable. This curing time is crucial to achieve the desired strength and durability of the refractory lining. On the other hand, low cement or ultra-low cement castables may require a longer curing time due to their reduced water content. These refractories often need a curing period of 48 to 72 hours to allow for proper bonding and solidification. For gunning mixes or shotcrete applications, the curing time might be shorter, usually around 8 to 12 hours. This faster curing process is facilitated by the addition of accelerators to the mix, which promote rapid setting and hardening. It is important to note that these recommended curing times are just general guidelines, and specific recommendations may vary depending on factors such as ambient temperature, humidity, and the specific refractory material being used. Therefore, it is always advisable to consult the manufacturer's instructions or seek guidance from a refractory specialist to ensure optimal curing and performance of the monolithic refractory.

- Q: How do monolithic refractories resist corrosion and erosion in the iron and steel industry?

- Monolithic refractories in the iron and steel industry are designed to resist corrosion and erosion through a combination of their composition and application techniques. Firstly, the composition of monolithic refractories includes high-quality raw materials such as alumina, magnesia, and silica. These materials possess excellent resistance to corrosion and erosion. Alumina, for example, is highly resistant to chemical attack and can withstand high temperatures, making it ideal for protecting against the corrosive nature of the iron and steel industry. In addition to the choice of materials, the application techniques used in installing monolithic refractories also play a crucial role in their resistance to corrosion and erosion. Monolithic refractories are typically installed using various methods such as gunning, ramming, or casting. These techniques ensure a tight and seamless bond between the refractory and the steel structure, minimizing the chances of corrosion and erosion. Furthermore, monolithic refractories can be customized to suit the specific needs of different parts of the iron and steel industry. For example, areas exposed to molten metal require refractories with high thermal conductivity and excellent resistance to chemical attack. By tailoring the refractory to the specific application, it becomes more effective in resisting corrosion and erosion. Moreover, monolithic refractories are often designed with additives or binders that enhance their resistance to corrosion and erosion. These additives can provide additional protection against chemical attacks from molten metal or corrosive gases, making the refractory even more durable in harsh conditions. Overall, monolithic refractories resist corrosion and erosion in the iron and steel industry due to their composition, application techniques, customization, and the inclusion of additives. By combining these factors, monolithic refractories provide excellent protection to the steel structures, ensuring their longevity and efficiency in the challenging environments of the iron and steel industry.

- Q: What are the common challenges faced by monolithic refractories in the iron and steel industry?

- The iron and steel industry heavily relies on monolithic refractories, which have a vital role in various applications like lining furnaces, ladles, and tundishes. However, these materials encounter common challenges in this industry. Thermal shock is a major challenge. Monolithic refractories undergo extreme temperature changes, especially during start-up and shut-down phases. This rapid heating and cooling can cause thermal stress, leading to cracking and spalling. To combat this, refractory manufacturers create high-quality monolithic materials with enhanced thermal shock resistance. Corrosion is another significant challenge. The iron and steel industry exposes refractory linings to aggressive materials like molten metal, slag, and gases, which chemically attack them. This corrosion results in material degradation, erosion, and reduced service life. To address this, specialized monolithic refractories with excellent corrosion resistance are used, often containing additives that can withstand the corrosive environment. Abrasion is also a common challenge faced by monolithic refractories in this industry. The movement of raw materials, molten metal, and slag causes mechanical wear on the refractory lining, leading to material loss and compromised performance. Refractory manufacturers develop abrasion-resistant monolithic materials that can withstand intense wear and tear, ensuring extended service life. Moreover, good thermal conductivity is often required in the iron and steel industry. This is crucial for efficient heat transfer and maintaining optimal operating conditions. Achieving the right balance between thermal conductivity and mechanical strength can be challenging, as refractories with high thermal conductivity often have lower mechanical strength. Therefore, selecting the appropriate monolithic refractory with desired thermal conductivity properties is crucial for optimal performance. Lastly, installation and maintenance present challenges for monolithic refractories. The application of these refractories requires skilled personnel and careful installation techniques due to their liquid or semi-liquid nature. Additionally, regular maintenance and repairs are necessary to ensure the refractory lining's longevity and performance. Regular inspections, repairs, and proper curing techniques are vital to mitigate these challenges and optimize refractory performance. In conclusion, monolithic refractories in the iron and steel industry face challenges such as thermal shock, corrosion, abrasion, thermal conductivity, and installation/maintenance. Addressing these challenges through the development of specialized refractory materials and employing proper installation and maintenance techniques are crucial for ensuring efficient and reliable performance in this demanding industry.

Send your message to us

Monolithic Refractory Castable Refractory Castable For Iron and Steel Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords