Monolithic Refractories for Iron and Steel Industry:Corundum Castable for EAF Roof

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Corundum Castable for EAF Roof

Made as per international standards, FIREF corundum castable for EAF roof is known for its excellent corrosion and scouring resistance of iron steel, long operating life and easy execution and mending. Further, FIREF corundum castable for EAF roof can be provided in different specifications as required by the clients.

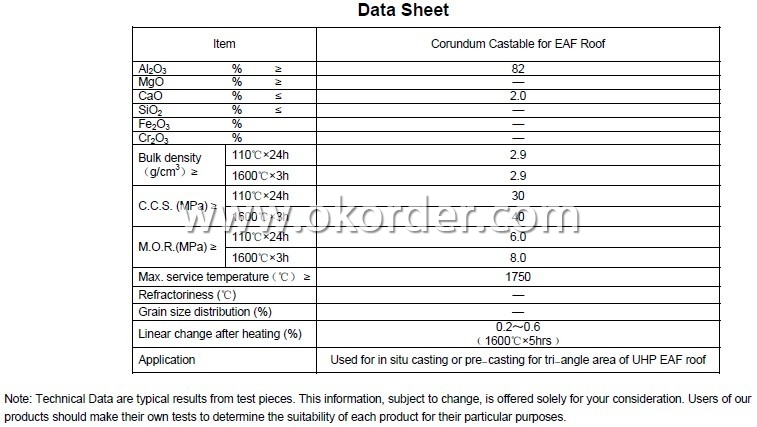

Technical data of Corundum Castable for EAF Roof

Production line and packing of Corundum Castable for EAF Roof

Feature of Corundum Castable for EAF Roof

Excellent corrosion and scouring resistance of iron steel

Long operating life

Easy execution and mending

Application of Corundum Castable for EAF Roof

FIREF corundum castable for EAF roof can be used widely for in situ casting or pre-casting for tri-angle area of UHP EAF roof.

Production Flow of Corundum Castable for EAF Roof

- Q: How are monolithic refractories inspected and tested for quality assurance?

- Monolithic refractories are inspected and tested for quality assurance through various methods. Visual inspections are conducted to check for any visible defects such as cracks, spalling, or other physical damages. In addition, non-destructive testing techniques like ultrasonic testing and X-ray inspection are used to detect any internal flaws or inconsistencies in the refractory material. Furthermore, mechanical testing such as compression and flexural strength tests are performed to evaluate the mechanical properties of the monolithic refractories. These inspections and tests ensure that the refractories meet the required quality standards and can withstand the harsh operating conditions they are designed for.

- Q: What are the common failure mechanisms of monolithic refractories in the iron and steel industry?

- Common failure mechanisms observed in monolithic refractories within the iron and steel industry include: 1. Thermal spalling: Monolithic refractories endure extreme temperature variations during the iron and steel production process. These rapid changes in temperature can cause the refractory material to expand and contract, resulting in thermal stress and eventual spalling. This failure mechanism is particularly prevalent in areas where the refractory is exposed to elevated temperatures, such as the hot face of a furnace. 2. Chemical attack: The iron and steel production process involves the utilization of various chemicals and molten metal, which can react with the refractory material over time. Chemical attack can lead to the deterioration of the refractory, resulting in cracks, erosion, and eventual failure. Slag, alkalis, sulfur, and other impurities present in the production environment are commonly responsible for this type of damage. 3. Abrasion: The movement of materials, such as iron ore, coke, and fluxes, can cause abrasion on the refractory lining. This mechanical wear and tear weaken the refractory material, eventually leading to failure. Areas experiencing high material flow rates or turbulence, such as tapholes or launder systems, are particularly prone to abrasion. 4. Corrosion: Monolithic refractories can be susceptible to corrosion caused by gases, liquids, and solids found in the iron and steel production environment. Corrosion occurs due to the presence of oxygen, water vapor, and various chemical compounds, such as carbon monoxide and sulfur compounds. It results in the formation of corrosive products, such as oxides or sulfides, which degrade the refractory material over time. 5. Mechanical stress: Monolithic refractories may undergo mechanical stress due to factors like thermal expansion and contraction, vibration, or mechanical impact. Excessive mechanical stress can lead to the development of cracks or fractures in the refractory lining, compromising its integrity and resulting in failure. To mitigate these failure mechanisms, it is crucial to select appropriate refractory materials, conduct regular inspections, and perform necessary maintenance. Furthermore, designing refractory linings that consider specific operational conditions and employing appropriate installation techniques can enhance their performance and lifespan within the iron and steel industry.

- Q: What are the challenges faced in the application of monolithic refractories?

- There are several challenges faced in the application of monolithic refractories. Firstly, one of the major challenges is the proper installation of monolithic refractories. Unlike traditional brick refractories that can be easily laid and stacked, monolithic refractories require specialized skills and techniques for proper application. The consistency and workability of the refractory material must be carefully controlled, and the installation process often requires the use of specialized equipment such as gunning machines or vibrating tools. Another challenge is the selection of the appropriate monolithic refractory material for a specific application. There are various types of monolithic refractories available, each with its own unique properties and suitability for different environments. Choosing the wrong type of refractory material can result in premature failure and costly repairs. Therefore, it is essential to understand the operating conditions, such as temperature, chemical exposure, and mechanical stress, to select the most suitable monolithic refractory material. Additionally, monolithic refractories are susceptible to thermal shock and erosion due to their composition and application method. They are typically made from fine powders that are mixed with water or other binding agents to form a paste. This paste is then applied and dried to form a solid refractory lining. However, during the heating and cooling cycles, monolithic refractories can experience thermal expansion and contraction, leading to cracking and spalling. Moreover, the chemical reactions occurring in some industrial processes can cause chemical attack and erosion of the refractory lining, reducing its lifespan. Furthermore, maintenance and repair of monolithic refractories can also be challenging. Unlike brick refractories that can be easily replaced, repairing monolithic refractories often requires skilled personnel and specialized techniques. The damaged area needs to be removed, and a new layer of refractory material must be applied, ensuring proper bonding and compatibility with the existing lining. This process can be time-consuming and costly, particularly in high-temperature applications where extended downtime can result in significant production losses. In summary, the challenges faced in the application of monolithic refractories include proper installation techniques, selection of the appropriate material, susceptibility to thermal shock and erosion, and complex maintenance and repair procedures. Overcoming these challenges requires expertise, careful planning, and a thorough understanding of the specific operating conditions and requirements for each application.

- Q: How are monolithic refractories used in the repair and maintenance of ladles and tundishes?

- Monolithic refractories are extensively used in the repair and maintenance of ladles and tundishes in the steel industry. These refractories are specially designed to withstand the extreme conditions of high temperatures, thermal shock, and chemical erosion that occur during the steelmaking process. When it comes to the repair of ladles, monolithic refractories are used to line the inner walls of the ladle. Ladles are subjected to intense heat and corrosive molten metal, and the refractory lining provides insulation and protection against these harsh conditions. The lining also helps to maintain the desired temperature of the molten metal, ensuring that it remains in a suitable state for processing. In the case of tundishes, monolithic refractories are used to line the bottom and sides of the tundish, as well as the nozzle and impact pad. Tundishes are responsible for distributing molten metal to multiple casting molds and are exposed to high temperatures and thermal shocks. The refractory lining helps to maintain the necessary temperature and prevent any leakage of molten metal. During the repair and maintenance process, monolithic refractories are applied as a dense, high-strength material that is easy to shape and install. They can be shaped into various forms such as bricks, castables, and gunning mixes, depending on the specific requirements of the ladle or tundish. These refractories are often applied using specialized techniques, such as gunning or casting, to ensure proper adhesion and longevity. In addition to their thermal and chemical resistance properties, monolithic refractories also offer excellent mechanical strength and resistance to abrasion. This is crucial in ladles and tundishes, as they are subjected to constant wear and tear from the movement of molten metal and the handling of refractory materials during repair and maintenance. Overall, monolithic refractories play a critical role in the repair and maintenance of ladles and tundishes in the steel industry. They provide the necessary insulation, protection, and durability required to withstand the demanding conditions of steelmaking.

- Q: How long is the lifespan of monolithic refractories in iron and steel applications?

- The lifespan of monolithic refractories in iron and steel applications can vary depending on several factors. These factors include the type of refractory material used, the specific application, the operational conditions, and the maintenance practices implemented. In general, monolithic refractories used in iron and steel applications are designed to withstand high temperatures, thermal shock, chemical attack, and mechanical stress. They are expected to have a relatively long lifespan compared to other refractory materials. Under normal operating conditions and proper maintenance, monolithic refractories can typically last anywhere from several months to several years in iron and steel applications. However, it is important to note that certain areas of the application may experience more severe conditions and may require more frequent repairs or replacements. Regular inspections and monitoring of the refractories' condition are crucial to identify any signs of deterioration or damage. Any necessary repairs or replacements should be carried out promptly to prevent further damage and minimize downtime. It is also worth mentioning that advancements in refractory technology and materials have led to the development of more durable and long-lasting monolithic refractories. These advancements have increased the lifespan of refractories in iron and steel applications, ultimately improving the overall efficiency and productivity of the operations.

- Q: How do monolithic refractories perform in reheating furnace roof applications?

- Monolithic refractories are highly effective in reheating furnace roof applications. These refractories are known for their excellent thermal shock resistance, which is crucial in the extreme temperature conditions inside a reheating furnace. They can withstand rapid temperature changes without cracking or spalling, ensuring the longevity and durability of the furnace roof. Additionally, monolithic refractories offer superior insulation properties, which help in maintaining the desired temperature inside the furnace. These refractories have low thermal conductivity, preventing heat loss and reducing energy consumption. This not only improves the energy efficiency of the furnace but also contributes to cost savings for the operators. Furthermore, monolithic refractories provide excellent resistance to chemical attacks from gases and molten metals present in the furnace environment. They are designed to withstand corrosive atmospheres and prevent the penetration of harmful substances, thus prolonging the life of the roof refractory. Moreover, monolithic refractories offer easy installation and repair options. Their ability to be cast or gunned in place allows for a seamless and precise application to the roof structure. This feature also enables quick and efficient repairs or maintenance, minimizing downtime and production losses. In conclusion, monolithic refractories are a reliable and efficient choice for reheating furnace roof applications. Their exceptional thermal shock resistance, insulation properties, chemical resistance, and ease of installation make them an ideal solution for maintaining the structural integrity and performance of the furnace roof.

- Q: How do monolithic refractories contribute to the reduction of heat loss in ladles and tundishes?

- The use of monolithic refractories is crucial in reducing heat loss in ladles and tundishes. These refractories are designed to have excellent thermal insulation properties, which effectively minimize the transfer of heat from the molten metal to the surrounding environment. Conduction is a key factor that contributes to heat loss in ladles and tundishes. It occurs when heat is transferred through direct contact with the refractory lining. However, monolithic refractories are specifically engineered to have low thermal conductivity, making them efficient in reducing heat transfer through conduction. This, in turn, helps to maintain the desired temperature of the molten metal for longer periods, resulting in lower energy consumption and improved process efficiency. Additionally, monolithic refractories also aid in reducing heat loss through radiation. They have high emissivity, meaning they emit a significant amount of thermal radiation. This emitted radiation creates a heat shield around the molten metal, preventing heat loss to the surroundings. By effectively trapping the radiant heat, monolithic refractories contribute to maintaining the desired temperature in ladles and tundishes, minimizing heat loss. Apart from their thermal insulation properties, monolithic refractories also offer excellent resistance to thermal shock and mechanical stress. This ensures that they remain intact and functional even in the harsh operating conditions of ladles and tundishes. The durability of these refractories further contributes to the reduction of heat loss by preventing any cracks or gaps in the refractory lining that could facilitate heat transfer. To summarize, monolithic refractories play a significant role in reducing heat loss in ladles and tundishes by minimizing heat transfer through conduction and radiation. Their thermal insulation properties, combined with their resistance to thermal shock and mechanical stress, help to maintain the desired temperature of the molten metal, improve energy efficiency, and enhance the overall performance of these metallurgical vessels.

- Q: What are the advantages of using low-moisture castables in the iron and steel industry?

- Low-moisture castables offer several advantages in the iron and steel industry. Firstly, they have a lower water content, which allows for faster and easier installation. This results in reduced downtime and increased productivity. Secondly, low-moisture castables have excellent strength and thermal shock resistance, making them highly durable in high-temperature applications. This helps to prolong the lifespan of refractory linings, saving on maintenance and replacement costs. Additionally, their low moisture content minimizes the risk of steam explosions during installation or curing. Lastly, these castables offer improved energy efficiency by reducing heat loss, resulting in lower fuel consumption and greenhouse gas emissions. Overall, the use of low-moisture castables in the iron and steel industry enhances operational efficiency, durability, and environmental sustainability.

- Q: What are the main factors affecting the erosion resistance of monolithic refractories?

- The erosion resistance of monolithic refractories is influenced by several key factors. These factors include the chemical composition of the refractory material, the microstructure of the material, the temperature and environment in which it is used, and the mechanical properties of the material. The chemical composition of the monolithic refractory plays a crucial role in its erosion resistance. Certain chemical elements and compounds can enhance the resistance of the refractory to erosion, while others may make it more susceptible. For example, the addition of alumina (Al2O3) in the refractory composition can improve its resistance to erosion, as it forms a protective layer on the surface. On the other hand, the presence of impurities or excess amounts of certain elements can weaken the refractory and increase its susceptibility to erosion. The microstructure of the monolithic refractory is another important factor affecting erosion resistance. The refractory's microstructure refers to the arrangement and distribution of its constituent particles. A well-structured microstructure with a uniform distribution of particles can provide better erosion resistance as it ensures a more even distribution of load during exposure to erosive forces. Conversely, a poorly structured microstructure with clusters or weak bonding between particles may lead to localized erosion and failure. The temperature and environment in which the refractory is used also significantly influence erosion resistance. High temperatures can cause thermal stresses, chemical reactions, and phase changes in the refractory material, all of which can affect its erosion resistance. Additionally, the presence of corrosive gases, liquids, or slags can accelerate erosion by promoting chemical reactions or attacking the refractory material, leading to its degradation. Lastly, the mechanical properties of the monolithic refractory, such as its strength, hardness, and toughness, contribute to erosion resistance. A refractory with higher mechanical strength and hardness can withstand erosive forces better than a weaker material. Similarly, a higher toughness helps the refractory resist cracking or spalling when subjected to impact or thermal shock, reducing its vulnerability to erosion. In summary, the erosion resistance of monolithic refractories is influenced by the chemical composition, microstructure, temperature and environment, and mechanical properties of the material. Understanding and optimizing these factors can help in developing refractories with improved erosion resistance for various industrial applications.

- Q: How do monolithic refractories withstand the thermal cycling in aluminum smelting applications?

- Monolithic refractories have been specifically developed to endure the extreme thermal cycling conditions that arise in aluminum smelting applications. The exceptional properties of these refractories enable them to withstand the rapid and repetitive heating and cooling cycles without experiencing significant damage or failure. A key characteristic of monolithic refractories is their remarkable thermal shock resistance, which allows them to withstand sudden temperature changes without cracking or spalling. Throughout the aluminum smelting process, the refractories are exposed to extreme temperatures when molten aluminum is poured into the molds or when the molten metal comes into contact with the refractory lining. It is essential for the refractories to quickly absorb and dissipate heat to prevent any thermal shock damage. Furthermore, monolithic refractories possess a high thermal conductivity, which facilitates the efficient transfer of heat away from the refractory lining. This effectively reduces the risk of thermal stress and thermal fatigue. By dispersing the heat generated during the smelting process, the refractories minimize temperature variations within the lining, thereby preventing the occurrence of cracks or fractures. Moreover, monolithic refractories exhibit excellent chemical resistance, a crucial characteristic in aluminum smelting applications. These refractories are formulated to resist the corrosive effects of molten aluminum and other chemicals present in the smelting process. By offering resistance to chemical corrosion, the refractories help maintain the integrity of the refractory lining and extend its service life. Additionally, monolithic refractories are often reinforced with fibers or other structural materials to enhance their mechanical strength and durability. These reinforcements provide added resistance against mechanical stresses, such as thermal expansion and contraction, which arise during the thermal cycling process. In conclusion, the purpose of monolithic refractories is to withstand the thermal cycling conditions encountered in aluminum smelting applications. Their exceptional thermal shock resistance, high thermal conductivity, excellent chemical resistance, and enhanced mechanical strength enable them to endure extreme temperature fluctuations without experiencing significant damage. These refractories play a crucial role in maintaining the integrity and efficiency of the smelting process in the aluminum industry.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Monolithic Refractories for Iron and Steel Industry:Corundum Castable for EAF Roof

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords