Monolithic Refractories for Iron and Steel Industry - 42.5R Castable for Fireside and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

42.5R Castable For Fireplace and Industrial Furnace in Iron and Steel

Product Description:

42.5R castable is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by the clients. The 42.5R castables are used high purity raw materials and additives as the main material, and made of under superfine powder adding technology.

Product Advantages:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, also has a fine working ability.They should be used with the same material products.

Product Applications:

For feature of 42.5R castable, they have excellent abrasion resistance, thermal shock resistance, high-temperature resistance, anti-corrode and have high intensity.

Designed for refractory lining of blast furnace iron and slag runners, skimmers and soon

They can be used in troughs of small and mid size BFs and in all positions of the troughs where fast tapping is required.

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

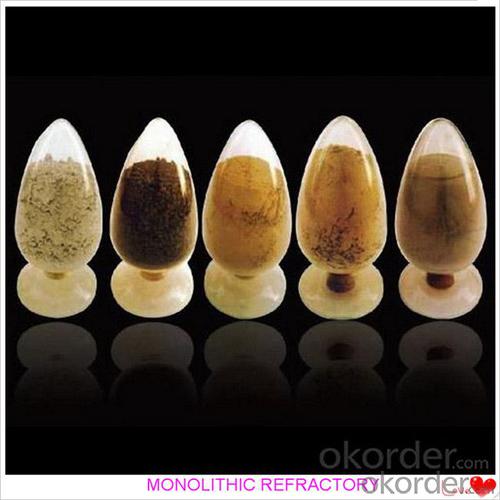

Product Picture:

- Q: What are the key trends in the use of monolithic refractories in the iron and steel industry?

- It is worth noting that there are several notable trends in the use of monolithic refractories in the iron and steel industry. First and foremost, there is an increasing demand for monolithic refractories due to their superior performance characteristics in comparison to traditional brick refractories. Monolithic refractories provide higher thermal shock resistance, superior insulation properties, and improved resistance to chemical attacks. As a result, they are being used more extensively in various applications within the iron and steel industry. Secondly, there is a shift towards the utilization of low-cement and ultra-low cement castables in monolithic refractories. These materials contain a reduced amount of cement, leading to enhanced refractory properties such as increased strength, better corrosion resistance, and improved resistance to thermal spalling. This trend is driven by the need to enhance the overall efficiency and longevity of refractory linings in iron and steel manufacturing processes. Another significant trend is the development of advanced monolithic refractories that prioritize sustainability and environmental performance. The iron and steel industry is facing mounting pressure to reduce its carbon footprint and minimize its impact on the environment. Consequently, there is a growing emphasis on the use of environmentally friendly binders and additives in monolithic refractories. These novel materials not only offer excellent refractory properties but also contribute to the industry's sustainability objectives. Moreover, there is an increasing focus on the development of monolithic refractories capable of withstanding extreme operating conditions. Iron and steel manufacturing processes involve high temperatures, aggressive chemical environments, and severe mechanical stresses. Consequently, there is a need for monolithic refractories that can withstand these harsh conditions without compromising their performance. The industry is investing in research and development to create refractories that exhibit exceptional resistance to thermal shock, abrasion, and erosion. Lastly, there is a growing adoption of digital and smart technologies for the monitoring and maintenance of monolithic refractories. Advances in sensor technology and data analytics have made it possible to collect real-time data on the condition and performance of refractory linings. This enables proactive maintenance, early detection of potential issues, and optimization of refractory usage, ultimately leading to improved operational efficiency and cost savings. In conclusion, the use of monolithic refractories in the iron and steel industry is witnessing key trends such as the demand for superior performance, the shift towards low-cement and ultra-low cement castables, the development of sustainable materials, the focus on extreme operating conditions, and the adoption of digital and smart technologies for monitoring and maintenance. These trends reflect the industry's continuous efforts to enhance the efficiency, durability, and environmental sustainability of refractory linings in iron and steel manufacturing processes.

- Q: How do monolithic refractories contribute to the overall efficiency of ladle transfer processes?

- Monolithic refractories play a crucial role in enhancing the overall efficiency of ladle transfer processes. These refractories are made of a single, homogeneous material, which allows for easy installation and maintenance. This feature significantly reduces downtime during the ladle transfer process, resulting in increased productivity. One way monolithic refractories contribute to efficiency is through their high thermal conductivity. Ladle transfer processes involve the transfer of molten metal, which generates immense heat. Monolithic refractories have excellent heat resistance, ensuring that they can withstand the extreme temperatures of the molten metal. This property prevents refractory failure and prolongs the lifespan of the ladle, leading to more efficient and uninterrupted ladle transfer operations. Additionally, monolithic refractories offer superior corrosion resistance. The corrosive nature of molten metal can cause significant damage to ladles over time. However, monolithic refractories are designed to withstand chemical attacks from molten metal, preventing the degradation of the ladle's integrity. As a result, ladles lined with monolithic refractories have a longer lifespan and require less frequent replacement, leading to cost savings and improved efficiency. Furthermore, the ability of monolithic refractories to conform to complex shapes and designs is another contributing factor to the efficiency of ladle transfer processes. Ladles come in various sizes and shapes, and the use of monolithic refractories allows for customized linings that perfectly fit the ladle's dimensions. This precise fit minimizes heat loss and maximizes energy efficiency during ladle transfer processes. Moreover, monolithic refractories offer excellent mechanical strength and resistance to thermal shock. Ladle transfer processes involve the handling and movement of ladles, which can subject refractories to mechanical stresses. The outstanding mechanical properties of monolithic refractories ensure their durability and prevent cracking or spalling, reducing the risk of refractory failure and improving the efficiency of ladle transfer operations. In summary, monolithic refractories contribute to the overall efficiency of ladle transfer processes by providing high thermal conductivity, corrosion resistance, precise lining fit, and excellent mechanical properties. These refractories enhance the ladle's durability, reduce downtime, and improve energy efficiency, resulting in cost savings and increased productivity in the steelmaking industry.

- Q: What are the recent developments in monolithic refractories for the iron and steel industry?

- Over the past few years, significant progress has been made in the field of monolithic refractories for the iron and steel industry. These refractories are vital in the production of iron and steel, as they provide insulation and withstand high temperatures in furnaces and other equipment. One major advancement is the development of advanced alumina-based castables. These castables offer exceptional thermal shock resistance, high strength, and excellent corrosion resistance, making them perfect for the iron and steel industry. They can endure extreme temperatures and mechanical stress, resulting in longer service life and less maintenance downtime. Another noteworthy development is the introduction of low-cement and ultra-low cement castables. Compared to traditional castables, these have reduced cement content, leading to improved refractory properties. They have higher hot strength, lower porosity, and increased resistance to slag and metal corrosion. This enhances productivity and efficiency in the iron and steel manufacturing processes. Moreover, insulating refractories have seen advancements in their usage. Insulating castables and bricks are now used to line ladles, tundishes, and other equipment, providing better insulation and energy efficiency. These materials help reduce heat loss and improve thermal efficiency, resulting in cost savings and reduced environmental impact. Additionally, there have been significant improvements in the installation techniques of monolithic refractories. Traditional brick lining methods require skilled labor and a longer installation time. However, the introduction of gunning and shotcreting techniques has made the process faster and more efficient. These techniques involve spraying refractory materials onto the lining surface, ensuring better adherence and reducing the risk of lining failure. Overall, recent developments in monolithic refractories for the iron and steel industry have focused on enhancing thermal shock resistance, corrosion resistance, insulation properties, and installation techniques. These advancements have led to increased efficiency, reduced downtime, and improved productivity in the iron and steel manufacturing processes.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish preheating stations?

- Monolithic refractories improve the efficiency of ladle and tundish preheating stations by providing excellent insulation properties and high thermal conductivity. This allows for better heat retention and transfer, resulting in faster and more efficient preheating of ladles and tundishes. Additionally, monolithic refractories offer improved resistance to thermal shocks and erosions, leading to longer service life and reduced downtime for maintenance and replacement.

- Q: How do monolithic refractories withstand thermal shock and mechanical stress?

- Monolithic refractories are engineered to withstand high temperatures and harsh working conditions, making them ideal for applications that involve thermal shock and mechanical stress. Firstly, monolithic refractories are designed with a high thermal conductivity, which allows them to quickly absorb and distribute heat. This property helps to minimize thermal gradients within the material, reducing the risk of thermal shock. When exposed to sudden temperature changes, the refractory material expands and contracts uniformly, preventing cracks and fractures from forming. Secondly, these refractories have excellent thermal shock resistance due to their low thermal expansion coefficient. This means that they have a minimal tendency to expand or contract when subjected to temperature fluctuations. As a result, they can withstand rapid changes in temperature without experiencing significant structural damage. Furthermore, monolithic refractories possess high mechanical strength, enabling them to withstand various types of mechanical stress. They are formulated with carefully selected raw materials and additives that enhance their load-bearing capacity and resistance to mechanical forces. This enables them to withstand the weight of the surrounding materials, as well as any external forces or vibrations that may be present in the application environment. Moreover, monolithic refractories have good structural integrity and stability, thanks to their dense and compact microstructure. These materials are typically formed by a combination of fine powders, binders, and additives, which are mixed and shaped to create a solid, cohesive structure. This structure provides resistance against mechanical stress, preventing the refractories from crumbling or disintegrating under pressure. In summary, monolithic refractories withstand thermal shock and mechanical stress through their high thermal conductivity, low thermal expansion coefficient, robust mechanical strength, and structural integrity. These properties make them reliable and durable materials for applications requiring resistance to extreme temperatures and challenging operating conditions.

- Q: What are the key properties of ramming mixes used for monolithic refractory installations?

- The key properties of ramming mixes used for monolithic refractory installations include high density, good flowability, high strength, excellent thermal shock resistance, chemical resistance, and low porosity. These properties ensure the ramming mix can be compacted easily during installation, withstand high temperatures without cracking, and resist chemical attacks from molten metals or corrosive gases. Additionally, low porosity helps to minimize heat loss and enhance the overall performance and longevity of the refractory lining.

- Q: How do monolithic refractories contribute to the overall efficiency of steel ladle operations?

- The overall efficiency of steel ladle operations can be greatly improved by the use of monolithic refractories. These refractories, which are engineered materials installed as a single structure within the ladle, offer numerous advantages that directly contribute to operational efficiency. One key benefit of monolithic refractories is their exceptional thermal insulation properties. They have a low thermal conductivity, meaning they are effective at retaining and containing heat within the ladle. This insulation helps to maintain the desired temperature of the molten steel, preventing heat loss during transportation and reducing the need for frequent reheating. By minimizing heat loss, monolithic refractories enable a more efficient use of energy resources, resulting in cost savings and improved productivity. Moreover, monolithic refractories possess a high refractoriness, meaning they can withstand high temperatures without losing their structural integrity. This is crucial in steel ladle operations, where extreme temperatures are encountered during the steelmaking process. The high refractoriness of monolithic refractories ensures that they can withstand the intense heat and avoid any damage or failure of the ladle lining. This durability translates into reduced downtime and maintenance requirements, leading to increased operational efficiency. Additionally, monolithic refractories offer excellent resistance to chemical attack. The ladles used in steelmaking come into contact with various corrosive substances, such as molten metals, slag, and fluxes. The chemical resistance of monolithic refractories prevents them from reacting with these substances, ensuring the integrity and longevity of the ladle lining. This resistance to chemical attack reduces the need for repairs and replacements, minimizing downtime and improving overall operational efficiency. Furthermore, the installation of monolithic refractories is relatively quick and straightforward compared to traditional brick linings. This ease of installation saves time and labor costs, allowing for a faster turnaround between ladle operations. It enables steel manufacturers to optimize their production schedules and enhance overall operational efficiency. In conclusion, monolithic refractories play a significant role in improving the efficiency of steel ladle operations. Their thermal insulation properties, high refractoriness, resistance to chemical attack, and ease of installation all contribute to enhanced energy efficiency, reduced downtime, and increased productivity. By choosing to use monolithic refractories, steel manufacturers can achieve optimized ladle performance and ultimately improve their steelmaking process as a whole.

- Q: What are the common failure mechanisms of monolithic refractories?

- Common failure mechanisms of monolithic refractories include thermal spalling, chemical attack, erosion, and mechanical stress. Thermal spalling occurs when the refractory material is exposed to rapid temperature changes, leading to the cracking and breaking of the refractory lining. This can happen due to thermal shock, such as when a cold material is suddenly exposed to high temperatures, or when the refractory is subjected to cyclic heating and cooling. Chemical attack occurs when the refractory material comes into contact with aggressive chemicals or gases that can react with and degrade the refractory lining. This can lead to the formation of new compounds or the dissolution of the refractory material, weakening its structure and reducing its resistance to further chemical attack. Erosion is another common failure mechanism, especially in applications where the refractory lining is exposed to high-velocity gas or liquid flows. The abrasive action of the flowing medium can gradually wear away the refractory material, leading to thinning and eventual failure of the lining. Mechanical stress, such as thermal expansion or contraction mismatch, can also cause failure in monolithic refractories. When the refractory material is subjected to rapid temperature changes, differential expansion or contraction can occur, leading to the development of cracks and fractures in the lining. To mitigate these failure mechanisms, various techniques can be employed, such as proper material selection based on the specific operating conditions, careful design to minimize thermal gradients, use of protective coatings, and regular inspection and maintenance to identify and address any signs of failure or degradation.

- Q: How do monolithic refractories perform in high-temperature environments?

- Monolithic refractories are highly effective in high-temperature environments due to their unique characteristics. These refractories are made from a single, continuous composition, as opposed to being composed of multiple bricks or tiles. This monolithic structure provides several advantages when it comes to performance in high-temperature conditions. Firstly, monolithic refractories have excellent thermal shock resistance. This means that they can withstand rapid temperature changes without cracking or spalling. High temperatures can cause significant stress on materials, but the monolithic structure allows for better expansion and contraction, reducing the risk of damage. Additionally, monolithic refractories have high resistance to chemical attack. In high-temperature environments, there are often aggressive chemical agents present that can corrode and erode traditional refractory materials. However, the monolithic composition is usually designed to be chemically inert, providing a protective barrier against these corrosive elements. Moreover, monolithic refractories offer superior strength and durability at high temperatures. Their single composition ensures a dense and compact structure, making them less prone to cracking or breaking under extreme thermal conditions. This strength allows them to maintain their integrity and performance even in the most demanding environments. Furthermore, monolithic refractories can be easily installed and repaired. Unlike traditional refractories, which require precise brick or tile placement, monolithic materials can be poured or sprayed into place, conforming to any shape or size. This flexibility makes installation faster and more cost-effective, reducing downtime and maintenance costs. Overall, monolithic refractories excel in high-temperature environments due to their thermal shock resistance, chemical inertness, durability, and ease of installation. Their ability to withstand extreme heat and harsh conditions makes them a preferred choice for industries such as steel, cement, glass, and petrochemicals, where high temperatures are common.

- Q: How do monolithic refractories help in enhancing the durability of iron and steel equipment?

- Monolithic refractories help enhance the durability of iron and steel equipment by providing a protective lining that withstands high temperatures, chemical corrosion, and mechanical stress. This lining acts as a barrier, preventing the contact between the equipment and harsh operating conditions, thus minimizing wear and extending the lifespan of the equipment.

Send your message to us

Monolithic Refractories for Iron and Steel Industry - 42.5R Castable for Fireside and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords