Mill Finish Aluminum Sheets AA1100 H14 for Curtain Wall and Building Boats

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Sheet AA1100 H14 for Curtain Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Aluminium Sheet AA1100 H14 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet AA1100 H14 for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

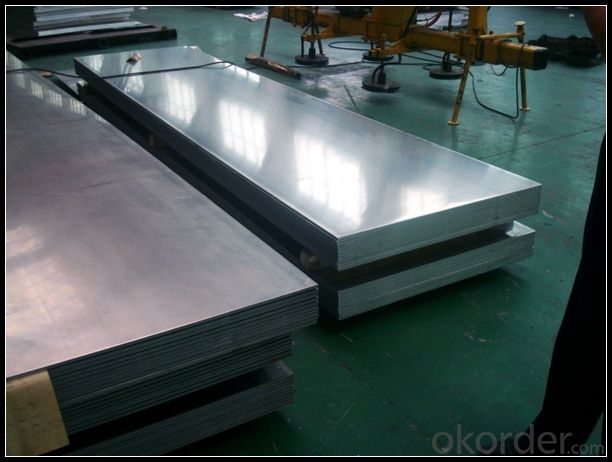

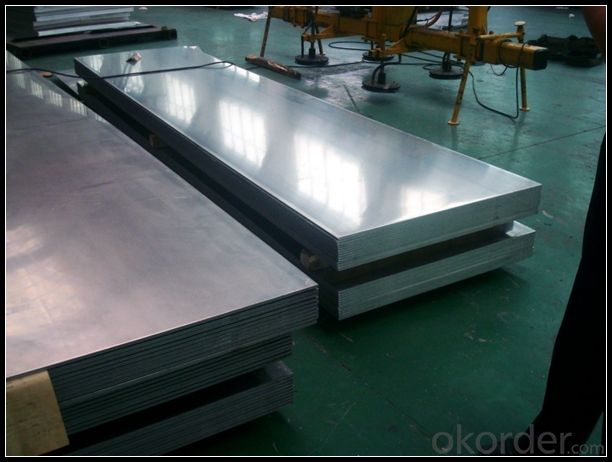

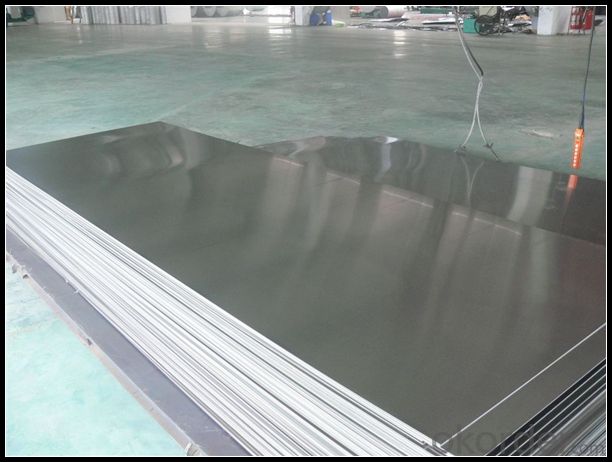

5. Image of Mill Finish Aluminium Sheet AA1100 H14 for Curtain Wall

6. Package and shipping of Mill Finish Aluminium Sheet AA1100 H14 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the maximum dimensions available for aluminum sheets?

- The maximum dimensions available for aluminum sheets depend on various factors such as the manufacturing process, supplier capabilities, and customer requirements. However, standard aluminum sheet sizes typically range from 0.02 inches (0.5 mm) to 0.25 inches (6.35 mm) in thickness, and widths can vary from 24 inches (609.6 mm) to 72 inches (1828.8 mm). The length of aluminum sheets can generally reach up to 144 inches (3657.6 mm). It is important to note that these dimensions may vary depending on the specific supplier or manufacturer, and custom sizes can be produced based on individual needs.

- Q: Are aluminum sheets suitable for chemical reactors?

- Yes, aluminum sheets are suitable for chemical reactors as they possess excellent corrosion resistance, high thermal conductivity, and are lightweight, making them ideal for various chemical reactions.

- Q: I have a lot of old aluminum cake pans, coffee pots, pots and pans and various old nuts and bolts made of aluminum. Would it be worth it to scrap them? They really aren't usable for cooking anymore. They are clean.

- if u live in wollongong australia there currently a dollar a kilo and my dad does it and puts the money towards down the coast...recycle copper its expensive over here

- Q: How do you prevent galvanic corrosion when using aluminum sheets with other metals?

- To prevent galvanic corrosion when using aluminum sheets with other metals, there are several actions that can be taken: 1. Applying a protective coating, like paint or anodizing, on the aluminum surface can create a barrier between the aluminum and other metals. This prevents direct contact and reduces the risk of galvanic corrosion. 2. To isolate the metals and prevent galvanic corrosion, a non-conductive insulating material such as rubber or plastic can be placed between the aluminum and other metals. 3. Choosing metals that are less prone to galvanic corrosion when in contact with aluminum can reduce the risk. For instance, stainless steel, titanium, or other corrosion-resistant alloys are commonly preferred when working with aluminum sheets. 4. Inserting a dielectric material like nylon or Teflon washers between the aluminum and other metals can act as a barrier. This inhibits the flow of electrical current and prevents galvanic corrosion. 5. Controlling the environment by avoiding high moisture levels or extreme temperature variations can help in reducing the likelihood of galvanic corrosion. Proper ventilation and moisture control also play a significant role in preventing this type of corrosion. It's important to note that the most effective preventive measures may vary depending on the specific application and the types of metals involved. Seeking advice from a materials engineer or corrosion specialist can offer valuable guidance in selecting the most appropriate strategies to prevent galvanic corrosion in a particular scenario.

- Q: Can aluminum sheets be used for chemical distillation columns?

- Yes, aluminum sheets can be used for chemical distillation columns. Aluminum is a commonly used material for constructing distillation columns due to its excellent thermal conductivity, corrosion resistance, and lightweight nature. It is particularly suitable for applications where the process conditions are relatively mild, such as low-pressure distillation or distillation of non-reactive substances. However, it is important to note that aluminum may not be suitable for all chemical distillations, especially those involving corrosive or reactive substances. In such cases, other materials like stainless steel or glass-lined steel may be more appropriate to ensure the column's durability and integrity.

- Q: Can aluminum sheets be used for sound insulation?

- Aluminum sheets possess a certain degree of effectiveness in sound insulation. Although aluminum is not as proficient in soundproofing as materials such as rubber or foam, it can still offer a certain level of sound insulation if utilized appropriately. One can employ aluminum sheets as a barrier or partition in walls, ceilings, floors, or other surfaces to decrease the transmission of sound waves. Nevertheless, it is noteworthy to mention that attaining optimal outcomes might require the inclusion of supplementary soundproofing materials or techniques.

- Q: Are aluminum sheets suitable for structural applications?

- Yes, aluminum sheets are suitable for structural applications. They are lightweight, yet strong and durable, making them ideal for various structural uses such as building facades, roofs, and transportation vehicles. Additionally, aluminum sheets have excellent corrosion resistance, which further enhances their suitability for structural applications.

- Q: I have some carbon arrows for my bow but I was wondering if aluminum arrows penetrate farther into a deer because they weigh more. I read somewhere that they do but I just wanted to confirm that.

- Aluminum arrows do not penetrate nearly as well as the carbon arrows do. The carbon arrows penetrate better due to the carbon arrow generating more speed then the aluminum arrow and the stiffness of the carbon arrow plays a factor in it's superior penetration. If you watch a slow motion video of an aluminum arrow striking a target, the arrow flexes several times upon impact. This absorbs some of the force of the arrow. Carbon on the other hand has almost zero flex when hitting the target, therefore all the power goes into Penetration. Another fact I found out when I made the switch to carbon arrows.They are actually cheaper to use then the aluminum.A dozen carbon arrows will last much longer then a dozen aluminum ones will.You can make an aluminum arrow worthless as a hunting shaft with a broad head on it by merely dinging it a little while target practicing.Or if it becomes bent even if unable to see with the naked eye will ruin it for use with a broad head. Carbon on the other hand will never bend or ding.They last forever unless a deer rolls over on it and breaks it. It took me forever to make the switch to carbon arrows, but once I did I will never go back to aluminum again.In the old days everyone thought that weight alone was the contributing factor to penetration. But now it has been discovered that speed and stiffness are even greater factors that contribute to penetration. Stick with the carbons.

- Q: Can aluminum sheets be used for protective barriers?

- Yes, aluminum sheets can be used for protective barriers. Aluminum is a lightweight and durable material that offers good resistance against impact, corrosion, and fire. It can be easily fabricated into sheets, making it suitable for various applications such as protective barriers in construction, transportation, and industrial settings.

- Q: Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation. Aluminum is a highly versatile and durable material that can be painted to enhance its appearance or match the surrounding environment. However, it is important to properly prepare the surface before painting to ensure adhesion and longevity of the paint. This typically involves cleaning the surface, removing any dirt or debris, and applying a suitable primer to promote better paint adhesion. Once the surface is prepared, any type of paint can be applied to the aluminum sheet, such as acrylic, oil-based, or epoxy paint. It is recommended to consult with a professional painter or follow the manufacturer's instructions for the specific paint product to achieve the best results.

Send your message to us

Mill Finish Aluminum Sheets AA1100 H14 for Curtain Wall and Building Boats

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords