Black Aluminum Diamond Plate Sheets - Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

Alloy Number | AA1xxx 3xxx 5xxx |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

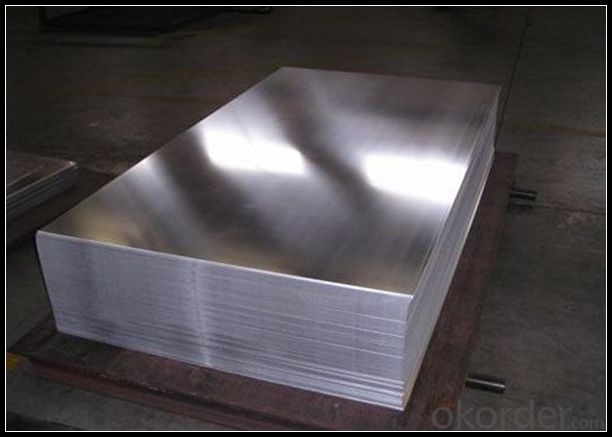

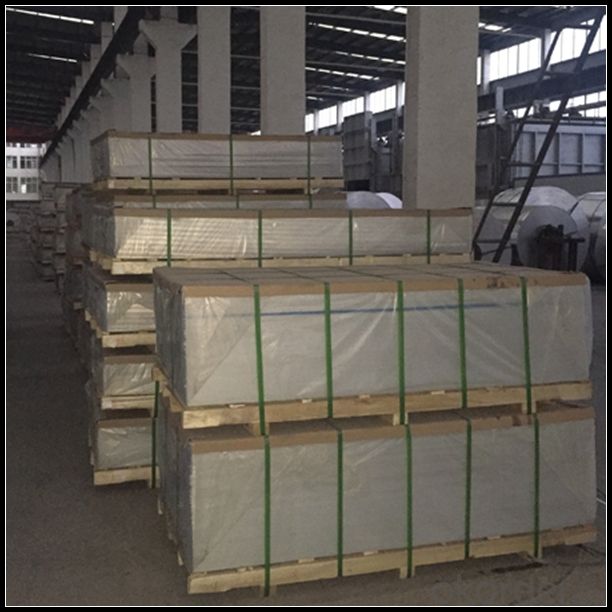

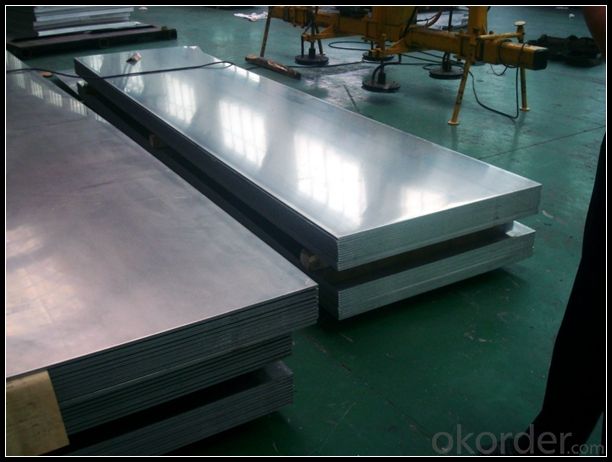

5. Image of Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

6. Package and shipping of Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are 101 aluminum sheets suitable for aircraft manufacturing?

- Yes, 101 aluminum sheets are suitable for aircraft manufacturing.

- Q: Are the aluminum sheets suitable for manufacturing lighting fixtures?

- Yes, aluminum sheets are suitable for manufacturing lighting fixtures. Aluminum is a lightweight and durable material that is corrosion-resistant, making it ideal for manufacturing various lighting fixtures. Additionally, aluminum can be easily molded and shaped, allowing for flexibility in design and customization.

- Q: Are aluminum sheets suitable for chemical storage applications?

- Yes, aluminum sheets are suitable for chemical storage applications. Aluminum is a corrosion-resistant material that can withstand exposure to various chemicals, making it a suitable choice for storing a wide range of chemicals safely.

- Q: Can aluminum sheets be perforated?

- Indeed, it is possible to perforate aluminum sheets. Perforating entails either punching holes or generating a pattern of holes in a material. Aluminum, being a flexible and adaptable metal, can be easily perforated through a variety of techniques like punching, drilling, or laser cutting. The perforation of aluminum sheets can have numerous applications, including facilitating airflow, reducing weight, improving aesthetics, or constructing filtration systems. The dimensions, form, and layout of the perforations can be tailored to satisfy particular demands and design preferences. In summary, perforating aluminum sheets can effectively enhance their functionality and visual allure.

- Q: Can 101 aluminum sheets be used for roofing or siding?

- Yes, 101 aluminum sheets can be used for roofing or siding.

- Q: Can the aluminum sheets be used for manufacturing musical instruments?

- Yes, aluminum sheets can be used for manufacturing musical instruments. Aluminum is a lightweight and versatile material that can be shaped and tuned to produce various musical sounds.

- Q: Are the aluminum sheets suitable for manufacturing automotive body panels?

- Indeed, automotive body panels can be manufactured using aluminum sheets. Aluminum, being a material that is both lightweight and robust, presents numerous advantages in the realm of automotive applications. Its high ratio of strength to weight enables enhanced fuel efficiency and superior overall vehicle performance. Furthermore, aluminum boasts exceptional corrosion resistance, rendering it suitable for enduring adverse environmental conditions. Moreover, its malleability and ease of manipulation facilitate the creation of intricate designs and shapes essential for automotive body panels. These attributes have established aluminum sheets as a highly favored option within the automotive industry for the production of body panels.

- Q: Can aluminum sheets be used in construction?

- Yes, aluminum sheets can be used in construction. They are commonly used for roofing, siding, and structural applications due to their lightweight, corrosion-resistant, and durable properties.

- Q: This question asks about the typical duration an aluminum roof sheet can last before it needs to be replaced or repaired.

- <p>The lifespan of aluminum sheets for roofing can vary depending on the quality of the material, installation, and environmental factors. On average, a well-maintained aluminum roof can last between 20 to 50 years. High-quality aluminum roofing materials, when properly installed, can even exceed this range, offering a lifespan of up to 70 years. However, it's important to note that regular inspections and maintenance are crucial to extend the life of any roofing material, including aluminum.</p>

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, you can use aluminum sheets to create a green building. Aluminum is a sustainable material due to its recyclability and energy efficiency in production. It has a high recycled content rate, reducing the need for raw material extraction. Additionally, aluminum's lightweight nature can lead to reduced energy consumption in transportation and construction. Its durability and resistance to corrosion can extend the life of a building, further contributing to sustainability. However, it's important to consider the entire lifecycle impact, including the energy used in aluminum production, and to source aluminum responsibly to ensure a truly green building.</p>

Send your message to us

Black Aluminum Diamond Plate Sheets - Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords