Aluminum Sheets Blanket - Color Coating Aluminum Sheet Plate AA3003 for Building Outside Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminium Sheet Plate AA3003 for Building Outside Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

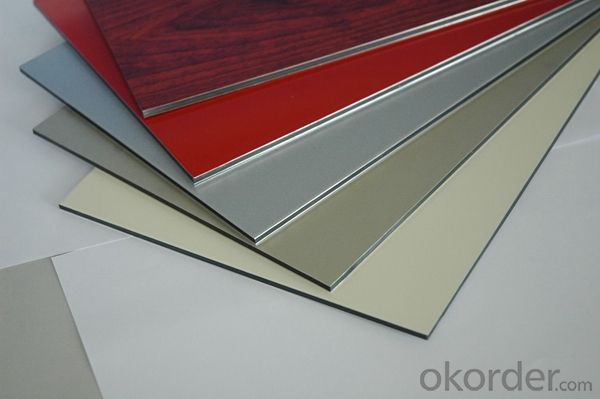

COLOR SERIES | RAL color number series |

2. Application of Color Coating Aluminium Sheet Plate AA3003 for Building Outside Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Sheet Plate AA3003 for Building Outside Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

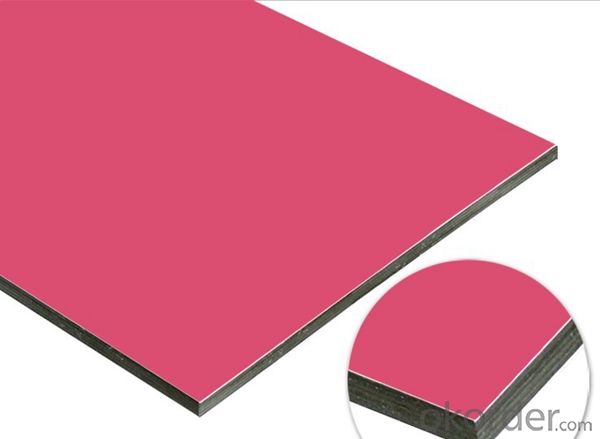

5. Image of Color Coating Aluminium Sheet Plate AA3003 for Building Outside Wall

6. Package and shipping of Color Coating Aluminium Sheet Plate AA3003 for Building Outside Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How does the reflective film stick to the aluminum plate?

- Put the plate clean, dry, reflective film a head from the aluminum back 2CM at the beginning attached to the aluminum plate, wrapping, pull to the front, back and side brush paper hanging tear reflective film side with the hanging brush to the aluminum paste, try to avoid bubbles.

- Q: Can 101 aluminum sheets be anodized for medical equipment applications?

- Yes, 101 aluminum sheets can be anodized for medical equipment applications. Anodizing is a process that creates a protective layer on the surface of aluminum, enhancing its corrosion resistance, durability, and aesthetic appearance. It is commonly used in the medical industry to improve the performance and longevity of equipment, as well as to maintain cleanliness and sterility. The specific alloy of aluminum used, such as 101, does not typically impact the anodizing process, as anodizing can be applied to various grades of aluminum. However, it is important to consult with an anodizing specialist or manufacturer to ensure that the specific alloy is suitable for the intended medical equipment application and to determine the most suitable anodizing process and specifications.

- Q: What are the common sizes of aluminum sheets?

- The common sizes of aluminum sheets vary, but some of the standard sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sizes are widely available and commonly used in various industries.

- Q: How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets generally exhibit excellent water resistance due to their natural oxide layer, which forms a protective barrier against corrosion. This oxide layer prevents water from penetrating the surface, making aluminum sheets highly resistant to water damage and rusting.

- Q: will it influence powder injection effect after wiping the oil contamination on the surface of aluminum sheet?

- It’s possible, there are several problems: 1, workers won’t wipe it thoroughly and fully, so you can wipe it after soaking. 2, the wiping efficiency is low, and we can use ultrasonic to clean it. 3, the water is poisonous and harmful to environment and workers’ health, so you can use water base to clean it, environmental and non-poisonous. Of course, if you really want to change, you can use detergent special for aluminum materials cleaning of our company, Changlvfeng chemical industry company. a, its PH value is 6.8-7.2 and it is totally an neutral liquid. b, good material applicability, detergent invented for aluminum materials. c, good degreasing ability, it has a good degreasing function for various oil contamination in processing and has no effect on material.

- Q: Our production needs a large number of plating aluminum plate, consult domestic and imported aluminum plate difference?

- Domestic aluminum plating mainly in Jiangsu origin, the general material is relatively hard, and the surface is not imported, aluminum plate bright and clean, but the price is lower than the import. Imported aluminum plate mainly in the eastern Pohang, South Korea, Japan's three major steel. Pohang is the three major steel plant, the material is more flexible and tensile properties. The relative price is higher than domestic.

- Q: Hey I just noticed that my deodorant/antiperspirant has aluminum in it. I remember reading that this is bad for you. My question is, will this be dangerous for my health in the long run?

- Yes. Use natural.

- Q: Can aluminum sheets be used for wall cladding?

- Yes, aluminum sheets can be used for wall cladding. Aluminum is a popular choice for cladding materials due to its lightweight nature, durability, and corrosion resistance. It is commonly used in commercial and residential buildings for wall cladding as it provides an attractive and modern aesthetic to the exterior of a structure. Aluminum sheets can be easily formed and fabricated into various shapes and sizes, allowing for flexibility in design. Additionally, aluminum cladding is low maintenance, requiring minimal cleaning and upkeep. Overall, aluminum sheets are a versatile and practical choice for wall cladding.

- Q: 1. Why does aluminium resist corrosion?2. How do we make aluminium stronger?3. Why does titanium resist corrosion?4. What properties make titanium ideal to use in jet engines and nuclear reactors?5. Why do we need electricity to make aluminium and titanium?6. Why does recycling aluminium save electricity?Even if you only know the answer to one question the help will be much appreciated :D

- 1. When exposed to air, pure aluminium rapidly forms a passive oxide layer, alumina, which further inhibits aluminium reactions with other elements. 2. Aluminium can be made stronger by alloying with other elements. One of the most known aluminum alloy is duraluminium, where the principal alloying component is copper. 3. Exactly as aluminium, titanium corrosion resistance is due to its high reactivity with oxygen. When pure titanium is exposed to air it forms a passive titanium dioxide layer on the surfaces exposed which further prohibits other reactions with corrosion agents. 4. The use of titanium in jet engines components is favored by its strength to weight ration, which is unmatched by any other metal. As for the nuclear reactors, its use is preferred because of its superior corrosion resistance associated with fracture toughness and overall durability. 5. Both titanium and aluminium are refined from their respective mined ores - bauxite, for aluminium, ilmenite and rutile for titanium. Basically, these are oxides of the metals. Pure metal has to be reduced from these ores and processes involve use of temperatures up to and sometime exceeding 1000 degrees Celsius, which obviously requires a great consumption of energy, including electricity. Moreover, pure aluminium is obtained in the final processing phase through electrolysis, meaning an electrical current is needed in order to drive the required chemical reactions, thus adding to the electrical consumption. 6. Recycling aluminium from aluminium simply requires the remelting of the metal, eliminating the electrolytic phase that is high electric energy consuming.

- Q: Are aluminum sheets suitable for industrial machinery?

- Yes, aluminum sheets are suitable for industrial machinery. Aluminum is a versatile and widely used material in various industries, including machinery and manufacturing. Aluminum sheets offer several advantages that make them suitable for use in industrial machinery. Firstly, aluminum sheets are lightweight. Compared to other metals like steel, aluminum has a significantly lower density, making it ideal for applications where weight reduction is important. The lightweight nature of aluminum allows for easier handling, transportation, and installation of machinery components, resulting in higher efficiency and lower costs. Secondly, aluminum sheets are highly corrosion resistant. Aluminum forms a natural oxide layer on its surface, which acts as a protective barrier against corrosion. This resistance to corrosion makes aluminum sheets suitable for use in industrial machinery, especially in environments where exposure to moisture, chemicals, or harsh weather conditions is common. Additionally, aluminum sheets have excellent thermal conductivity. This property allows aluminum to quickly and efficiently dissipate heat, making it suitable for applications where machinery components generate significant heat. By effectively managing heat, aluminum sheets help prevent overheating and prolong the lifespan of machinery. Furthermore, aluminum sheets are easily formable and can be fabricated into various shapes and sizes, making them adaptable to different machinery designs and requirements. They can be easily machined, welded, and joined, allowing for easy integration into industrial machinery manufacturing processes. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable without losing its properties, reducing the environmental impact of industrial machinery production and disposal. In conclusion, aluminum sheets are suitable for industrial machinery due to their lightweight nature, corrosion resistance, thermal conductivity, formability, and sustainability. These qualities make aluminum sheets an excellent choice for various applications in the machinery and manufacturing industries.

Send your message to us

Aluminum Sheets Blanket - Color Coating Aluminum Sheet Plate AA3003 for Building Outside Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords