Diamond Plate Aluminum Sheets Phoenix - White Aluminum Sheet Alloy 3003 for Wall Systems

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

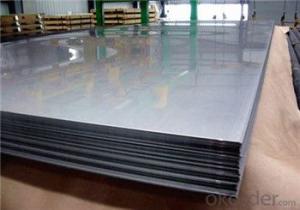

1.Structure of White Aluminum Sheet Alloy 3003 for Wall Systems

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of White Aluminum Sheet Alloy 3003 for Wall Systems

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

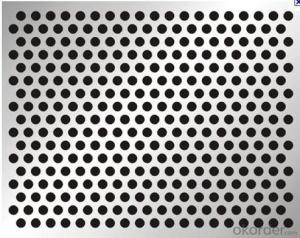

3. White Aluminum Sheet Alloy 3003 for Wall Systems Images

4.Specification of Aluminum Sheet 6061 for Window And Door System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What are the rules and standards that govern the use of aluminum sheets in construction projects?

- <p>Yes, there are regulations regarding the use of aluminum sheets in construction. These regulations vary by country and region but generally cover aspects such as material standards, safety, and environmental impact. For instance, in the United States, the American Society for Testing and Materials (ASTM) provides standards for aluminum sheet materials. Building codes like the International Building Code (IBC) also specify requirements for the use of aluminum in construction. These regulations ensure that aluminum sheets meet certain strength, durability, and performance criteria. Compliance with these regulations is crucial for safety, structural integrity, and to obtain necessary permits and approvals for construction projects.</p>

- Q: It is a club aluminium dutch oven from the 50's. It is discolored on the interior and has baked on dirt on the exterior. The exterior has a textured surface which makes cleaning more difficult. I tried baking soda and water paste, but it did not budge it!

- Even though it's a keepsake, you might think of switching to stainless steel. It's questionable whether the aluminum is healthy since elements of the metal may taint your food and get into your body.

- Q: Are aluminum sheets suitable for transportation applications?

- Yes, aluminum sheets are suitable for transportation applications. Aluminum is lightweight, durable, and corrosion-resistant, making it an ideal choice for various transportation components such as body panels, frames, and structural parts in vehicles, aircraft, and ships. Its high strength-to-weight ratio allows for improved fuel efficiency and load capacity. Additionally, aluminum is easily recyclable, contributing to sustainability in the transportation industry.

- Q: I had this mandarin orange can. I filled the can with water. Four days later, there are quarter inch thick rust cakes on the inside of the can. Since I assume the can is aluminum, are these cakes aluminum oxide? If so, is it flammable and/or dangerous?

- Aluminum oxide is white and powdery in texture. It also takes a bit longer for aluminum to oxidize than iron, so I don't think you could have cakes of aluminum oxide in 4 days. If the cakes you are describing are reddish in color, then no, it is NOT aluminum oxide. It is good old fashioned ferric oxide- rust from iron.

- Q: What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot can vary depending on the thickness or gauge of the sheet. On average, a 1/8 inch thick aluminum sheet weighs around 1.9 pounds per square foot. However, thinner sheets may weigh less, while thicker sheets can weigh more. It is important to consider the specific thickness of the aluminum sheet when determining its weight per square foot.

- Q: The diameter of a hole drilled through aluminum at 22°C is 7.50 mm. Find the diameter and the area of the hole at 89°C.

- Aluminum okorder / So 7.50 * 22.2 * 10-6 * 89 = 0.0111555 mm diameter increase (should only report 3 sig figs, so 7.51 mm). The area is then pi / 4 * d^2 = 44.31017 (so 44.3) mm^2

- Q: What is aluminium plate for?

- Two outdoor and indoor, outdoor curtain wall decoration, indoor ceiling (such as aluminum pinch plate, aluminum grille, aluminum hanging tablets, etc.), color diversity, but also can be made imitation wood grain, imitation marble and other colors, widely used

- Q: What is the typical torsional strength of aluminum sheets?

- The typical torsional strength of aluminum sheets can vary depending on various factors such as the alloy composition, thickness, and manufacturing process. However, aluminum generally possesses good torsional strength, making it suitable for a wide range of applications.

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

- Q: What are the cost considerations when purchasing aluminum sheets?

- When purchasing aluminum sheets, there are several cost considerations to take into account. First and foremost, the price of aluminum sheets is determined by the current market conditions. The price of aluminum is influenced by factors such as supply and demand, global economic conditions, and geopolitical events. Therefore, it is essential to stay updated on market trends and fluctuations to make an informed purchasing decision. Another cost consideration is the quantity of aluminum sheets needed. Purchasing in bulk or larger quantities often results in lower per-unit costs. However, it is crucial to assess the required quantity accurately to avoid excess inventory and unnecessary expenses. Additionally, the grade and quality of aluminum sheets can impact their price. Aluminum sheets are available in various grades, each with specific properties and performance characteristics. Higher-grade aluminum sheets, such as those with superior strength or corrosion resistance, tend to be more expensive. It is important to evaluate the specific requirements of the project to determine the appropriate grade of aluminum sheets needed. Transportation costs are another factor to consider when purchasing aluminum sheets. Depending on the supplier's location and the quantity ordered, shipping expenses can vary significantly. It is advisable to explore different shipping options and negotiate favorable terms to minimize transportation costs. Lastly, it is essential to consider additional costs such as processing, finishing, and customization. Some projects may require additional services like cutting, bending, or coating the aluminum sheets. These services can add to the overall cost but may be necessary to meet specific project requirements. Overall, when purchasing aluminum sheets, it is crucial to consider the current market price, required quantity, grade and quality, transportation costs, and any additional processing or customization needs. By carefully evaluating these cost considerations, one can make a well-informed decision and ensure the best value for their investment.

Send your message to us

Diamond Plate Aluminum Sheets Phoenix - White Aluminum Sheet Alloy 3003 for Wall Systems

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords