Aluminum Sheets Brooklyn - Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

Alloy Number | AA1xxx 3xxx 5xxx |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

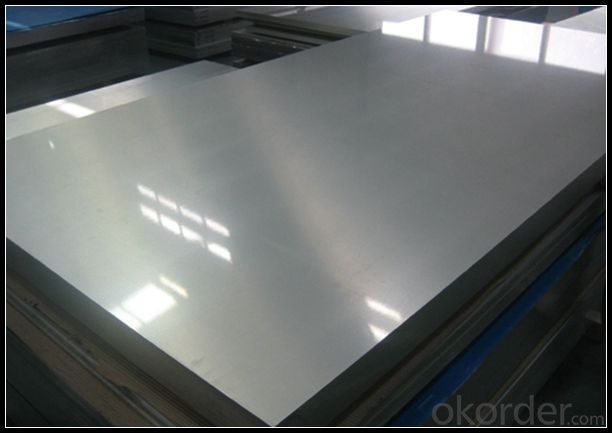

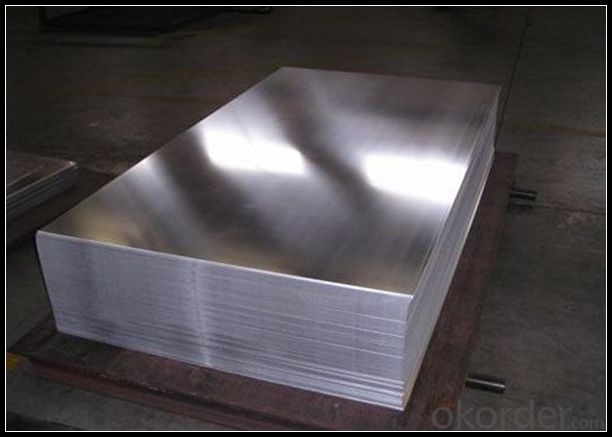

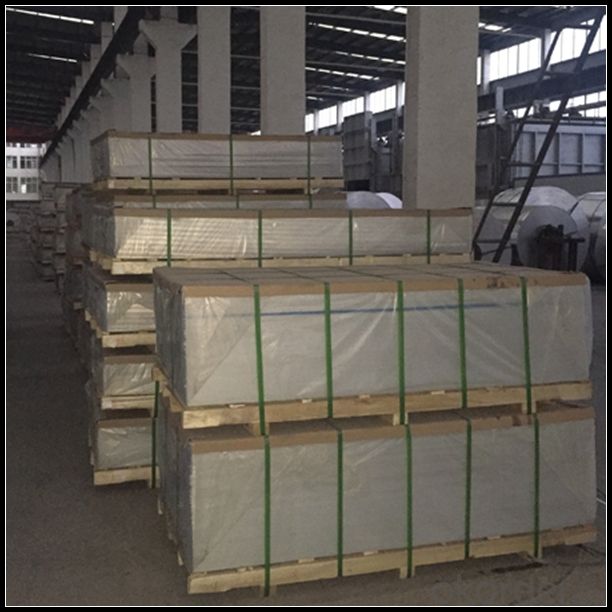

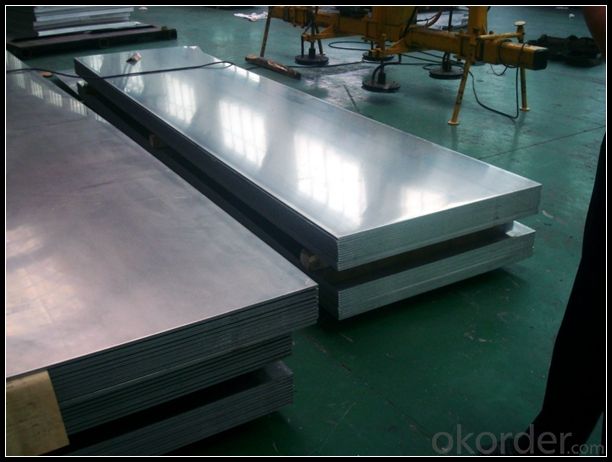

5. Image of Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

6. Package and shipping of Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to substitute traditional wooden windows and doors with aluminum sheets?

- <p>Yes, you can use aluminum sheets to replace traditional wooden windows and doors. Aluminum is a popular choice due to its durability, low maintenance, and resistance to weather and pests. It also offers good thermal performance and can be designed to mimic the appearance of wood. However, it's important to consider factors like insulation, cost, and the specific design requirements of your project before making the switch.</p>

- Q: This question asks if there are any potential risks or hazards associated with using windows that are manufactured from recycled materials.

- <p>There are generally no significant safety concerns with using windows made from recycled materials. These windows are often made from recycled plastics or glass, which are processed to ensure they meet safety and quality standards. However, it's important to ensure that the recycled materials used are free from contaminants and are processed correctly to maintain structural integrity. Additionally, the manufacturing process should adhere to environmental and safety regulations to prevent any health or environmental risks. Always check for certifications and standards that the windows meet to ensure their safety and reliability.</p>

- Q: Can aluminum sheets be used for curtain walls?

- Certainly, curtain walls can utilize aluminum sheets. Aluminum proves to be a favored option for curtain wall systems because of its lightweight, enduring, and corrosion-resistant properties. Aluminum sheets can be effortlessly molded into different forms and dimensions, rendering them ideal for crafting the structural framework of curtain walls. Moreover, aluminum can undergo coating or anodization processes to enhance its visual appeal and offer extra safeguard against weather conditions. Consequently, aluminum sheets emerge as a versatile and pragmatic material for erecting curtain walls in both commercial and residential structures.

- Q: What is aluminium plate L2-Y2?

- China plastic deformation of pure aluminum grades are 1080, 1080A, 1070, 107000A (L1), 1370, 1060, 1050 (L2), 1050A (L3), 1A50 (LB2), 1350, 1145, 1035 (L4), 1A30 (L4-1), 1100 (L5-1), 1200 (L-5), 1235. Iron and silicon are their major impurities and are increasing by the number of brands.2, Y2: indicates that the material is in a semi hard state

- Q: Can aluminum be either conductive or magnitized?

- Aluminum is conductive. In fact at one point in time it was used as an alternative to copper wiring for home electrical wiring. (There were problems, so it is no longer used).

- Q: How does my world Pocket Monster mod aluminum plate synthesize?

- Right on the ball cover and the aluminum ball low and then use the hammer on the anvil.

- Q: has aluminum sheet reacted with concentrated sulfuric acid?

- it can be regarded as no reaction, concentrated sulfuric acid will make aluminum's surface inactivation,and produce a layer of dense aluminium oxide film which will prevent further reaction.

- Q: This question asks for a comparison between aluminum sheets that have undergone anodizing treatment and those that have not, highlighting their distinct characteristics.

- <p>Anodized aluminum sheets are aluminum that has been treated with an electrochemical process to increase its thickness and durability, forming a protective oxide layer on the surface. This process enhances corrosion resistance, wear resistance, and allows for a wide range of colors. Non-anodized aluminum sheets, on the other hand, have not undergone this treatment and are more prone to corrosion and less durable. They also have a more limited color range and are generally softer and less resistant to wear.</p>

- Q: Can 101 aluminum sheets be anodized in different colors?

- Indeed, it is possible to anodize 101 aluminum sheets in various hues. Anodization entails generating an oxide coating on the aluminum's surface, which can then be dyed to attain a plethora of colors. The quantity of sheets, in this instance 101, does not impede the capacity to anodize them in distinct shades. Every sheet can be anodized and dyed separately to produce a distinct and preferred color. Anodization is a versatile procedure that facilitates customization and color diversity, enabling the achievement of diverse tones and tints on each individual aluminum sheet.

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into diluted hydrochloric acid?

- Aluminum element is extremely activated and will react with oxygen, generating aluminum oxide, once being exposed in air, so there is a layer of aluminum oxide on the surface of daily aluminum products including aluminum sheet. When aluminum sheet is put into diluted hydrochloric acid, aluminum oxide on the surface will firstly react with hydrochloric acid, generating aluminium chloride and water, the process won’t generate bubble, but after finishing the reaction of aluminum oxide on the surface, when the exposed aluminum element reacts with hydrochloric acid, generating aluminium chloride and oxygen, the bubble appears.

Send your message to us

Aluminum Sheets Brooklyn - Mill Finish Aluminium Sheet Alloy AA1060 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords