High Quality Square Steel With Low Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Square Steel:

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q235 or equivalent.

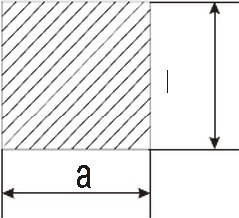

(The section of Square Steel)

Some details of Square Steel:

-List 1. The Chemical Composition.

|

Standard |

Grade |

Element (%) | ||||

|

GB |

Q235B |

C |

Mn |

S |

P |

Si |

|

0.12~0.20 |

0.3~0.7 |

≤0.045 |

≤0.045 |

≤0.3 | ||

-List 2.The length of a side and the theoretical weight of Square Steel.

|

Length of a side(mm) |

Theoretical weight(kg/m) |

Length of a side(mm) |

Theoretical weight(kg/m) |

|

6 |

0.283 |

32 |

8.04 |

|

7 |

0.385 |

*33 |

8.55 |

|

8 |

0.502 |

34 |

9.07 |

|

9 |

0.636 |

*35 |

9.62 |

|

10 |

0.785 |

36 |

10.17 |

|

11 |

0.950 |

38 |

11.24 |

|

12 |

1.13 |

40 |

12.56 |

|

13 |

1.33 |

42 |

13.85 |

|

14 |

1.54 |

45 |

15.90 |

|

15 |

1.77 |

48 |

18.09 |

|

16 |

2.01 |

50 |

19.63 |

|

17 |

2.27 |

53 |

22.05 |

|

18 |

2.54 |

*55 |

23.6 |

|

19 |

2.82 |

56 |

24.61 |

|

20 |

3.14 |

*58 |

26.4 |

|

21 |

3.46 |

60 |

28.26 |

|

22 |

3.80 |

63 |

31.16 |

|

*23 |

4.15 |

*65 |

33.17 |

|

24 |

4.52 |

*68 |

36.3 |

|

25 |

4.91 |

70 |

38.49 |

|

26 |

5.30 |

75 |

44.16 |

|

*27 |

5.72 |

80 |

50.24 |

|

28 |

6.15 |

85 |

56.72 |

|

*29 |

6.60 |

90 |

63.59 |

|

30 |

7.06 |

95 |

70.85 |

|

*31 |

7.54 |

100 |

78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 3. The allowed tolerance of Square Steel:

|

Length of a side(mm) |

Allowed Tolerance | ||

|

Group1 |

Group2 |

Group3 | |

|

5.5~7 |

±0.20 |

±0.30 |

±0.40 |

|

7~20 |

±0.25 |

±0.35 |

±0.40 |

|

20~30 |

±0.30 |

±0.40 |

±0.50 |

|

30~50 |

±0.40 |

±0.50 |

±0.60 |

|

60~80 |

±0.60 |

±0.70 |

±0.80 |

|

80~110 |

±0.90 |

±1.0 |

±1.1 |

|

110~150 |

±1.2 |

±1.3 |

±1.1 |

|

150~190 |

―― |

―― |

±2.0 |

|

190~250 |

―― |

―― |

±2.5 |

Usage/Applications of Square Steel:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for square tubes.

Packaging & Delivery of Square Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation & Marking:

-Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

-Marks:

1, Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

2, Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

Photos of Square Steel:

- Q: Can a steel square be used for cabinet door hinge installation?

- Yes, a steel square can be used for cabinet door hinge installation. It can help ensure the hinges are properly aligned and at a 90-degree angle to the door and cabinet frame.

- Q: How do you use a steel square to determine the length of a stair stringer?

- To use a steel square to determine the length of a stair stringer, you will need to follow a few steps: 1. Start by measuring the total rise of the stairs, which is the vertical distance from the top of the landing to the ground or the lower landing. Ensure this measurement is accurate as it is crucial for determining the length of the stringer. 2. Next, measure the total run, which is the horizontal distance covered by the stairs. This measurement should be taken from the edge of the upper landing to the edge of the lower landing or the ground. Again, precision is important for accurate results. 3. Once you have both the rise and run measurements, use the steel square to calculate the length of the stringer. Place the square on a flat surface with the blade (long side) firmly against the edge. 4. Align the tongue (short side) of the square with the bottom edge of the stringer material. Ensure the blade extends past the top edge of the stringer. 5. Using the rise measurement, mark the blade of the square at the appropriate point along the run measurement. For instance, if the rise is 7 inches and the run is 10 inches, mark the blade at the 7-inch point measured from the edge. 6. Carefully remove the square from the stringer material and draw a straight line from the bottom corner of the stringer to the mark on the blade. This line will represent the length of the stringer. 7. Repeat this process for the opposite side of the stringer, if applicable, to achieve symmetry. By following these steps and using a steel square properly, you can accurately determine the length of a stair stringer. Remember to double-check your measurements and calculations to ensure the safety and stability of the stairs.

- Q: Can a steel square be used for woodworking projects?

- Yes, a steel square can be used for woodworking projects. It is a versatile tool that can be used for measuring and marking right angles, checking the squareness of corners, and guiding the cuts of various woodworking joints. However, some woodworkers prefer using a combination square or a try square, which have wooden or plastic handles that provide a more comfortable grip and reduce the risk of marring the wood.

- Q: What are some alternative tools to a steel square?

- There are several alternative tools to a steel square that can be used for various tasks. Some of these alternatives include: 1. Framing Square: A framing square is a larger version of a steel square that is commonly used in carpentry and framing projects. It consists of two arms, one long and one shorter, forming a right angle. The longer arm typically has measurements and markings for easy angle and length calculations. 2. Combination Square: A combination square is a versatile tool that combines a ruler, a square, and a level. It is commonly used in woodworking and metalworking projects for measuring, marking, and checking right angles. 3. Speed Square: A speed square, also known as a rafter square or a triangle square, is a triangular-shaped tool that is commonly used in roofing and carpentry projects. It has multiple functions, including measuring and marking angles, determining roof pitches, and acting as a saw guide. 4. Sliding T-Bevel: A sliding T-bevel is a tool used for transferring and measuring angles. It consists of a handle and a blade that can be adjusted to any desired angle and locked in place. It is commonly used in woodworking and metalworking projects for marking and replicating angles. 5. Angle Finder: An angle finder is a tool used to measure and transfer angles accurately. It usually consists of two arms with pivoting joints that allow for easy adjustment and locking. Angle finders are commonly used in carpentry, metalworking, and construction projects. 6. Digital Angle Finder: A digital angle finder is a more advanced version of an angle finder. It typically has a digital display that provides precise angle measurements. This tool is particularly useful when working with complex angles or when a high level of accuracy is required. These alternative tools can be great substitutes for a steel square, depending on the task at hand. They offer different functionalities and features that cater to specific needs and preferences.

- Q: How do you use a steel square for marking crown molding angles?

- To use a steel square for marking crown molding angles, you will need to follow a few steps. 1. Start by ensuring that your steel square is clean and free from any debris or rust. This will help ensure accurate measurements and markings. 2. Measure the width of your crown molding using a tape measure. This measurement will determine the position of the square on the molding. 3. Hold the steel square against the edge of the crown molding, aligning it with the width measurement you took earlier. Ensure that the square is firmly pressed against the molding. 4. Use a pencil to mark the angle on the crown molding. The angle will be determined by the position of the square against the molding. 5. Repeat this process for each piece of crown molding that requires marking. 6. Once you have marked all the angles, you can then cut the crown molding using a miter saw or hand saw, following the marked lines. It is important to note that using a steel square for marking crown molding angles requires accuracy and precision. Take your time to ensure that the square is aligned properly, and double-check your measurements and markings before cutting the molding. Practice and experience will also help improve your proficiency in using a steel square for this purpose.

- Q: Can a steel square be used for cabinet making?

- Cabinet making can indeed make use of a steel square. Known by various names such as framing square or carpenter's square, a steel square is a versatile tool widely employed in woodworking. Although not specifically designed for cabinet making, it remains highly effective in carrying out diverse tasks throughout the cabinet making process. Made from durable steel, the steel square consists of two arms, one longer than the other, which intersect at a right angle. Its primary function is to mark and measure angles, ensure squareness, and facilitate precise and accurate cuts. These attributes make it an indispensable tool for cabinet making. When constructing cabinets, the steel square proves invaluable in determining and marking appropriate angles and measurements for cutting and joining cabinet components, such as panels, shelves, and doors. By employing the steel square, the cabinet's squareness and alignment can be guaranteed, resulting in a well-constructed and structurally sound piece of furniture. Furthermore, the steel square is useful in gauging the squareness of corners and joints, thereby guaranteeing perfect 90-degree angles. This aspect is crucial in achieving a professional and seamless finish in cabinet making. Although specialized tools exist for specific cabinet making tasks, the steel square offers versatility and cost-effectiveness, meeting a wide range of measurement and marking requirements. Consequently, it is a staple in the toolboxes of both amateur and professional cabinet makers alike.

- Q: Can a steel square be used for checking the plumbness of a support beam?

- Typically, a steel square is not employed to assess the plumbness of a support beam. A steel square, otherwise referred to as a framing square or carpenter's square, is primarily utilized in carpentry and woodworking to measure and mark right angles. Although it may assist in different construction tasks, it is not specifically crafted for plumbness verification. For this purpose, it is advisable to employ a plumb bob or a spirit level, both of which are explicitly designed and offer more precise outcomes.

- Q: Can a steel square be used for checking the squareness of a door frame?

- The squareness of a door frame can indeed be checked using a steel square. A steel square, also referred to as a framing square or carpenter's square, is a versatile tool commonly employed in construction and woodworking. With its 90-degree angle, it aids in determining whether something is square or perpendicular. To assess the squareness of a door frame utilizing a steel square, simply position one arm of the square flush against the inner edge of the door frame and the other arm against the inner edge of the adjacent wall. By visually examining the alignment of the square with the frame and wall, one can ascertain whether the frame is square or if any adjustments are necessary. Nevertheless, it is worth noting that while a steel square can provide a decent initial indication of squareness, it may not be as precise as more specialized tools like a laser level or a framing square. Furthermore, it is crucial to take into account the overall stability of the door frame, as additional checks and adjustments may be required to ensure proper installation.

- Q: Can a steel square be used for measuring and marking out stairs?

- Stairs can be accurately measured and marked out using a steel square. A steel square, also called a framing square or carpenter's square, is a versatile tool utilized by carpenters and other tradespeople for various tasks, including measuring, marking, and checking right angles. Specifically for stairs, a steel square guarantees precise measurements and angles, resulting in well-aligned and accurate staircases. Its straight edges and perpendicular sides are perfect for measuring the rise and run of each step, ensuring consistency and levelness. Moreover, the square's inside corner can be utilized to mark out the inclined supports, known as stringers, which hold the steps in position. Ultimately, a steel square is a dependable and effective tool for measuring and marking out stairs.

- Q: Can a steel square be used for checking the squareness of a table top?

- Yes, a steel square can be used for checking the squareness of a table top. A steel square, also known as a try square or engineer's square, is a measuring tool with a 90-degree angle that is commonly used to ensure the accuracy and squareness of various objects, including table tops. To check the squareness of a table top, you can place the steel square against one edge of the table and align it with the adjacent edge. If the square fits perfectly against both edges and creates a right angle, then the table top is square. If there is any gap or the square does not align properly, it indicates that the table top is not square and may require adjustments.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Middle east; Southeast Asia; Africa; East Aisa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20%-35% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Square Steel With Low Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords