Mild Steel Square Billet for Section Steel Production in Factory Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

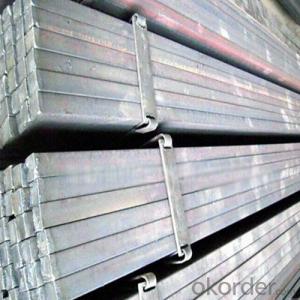

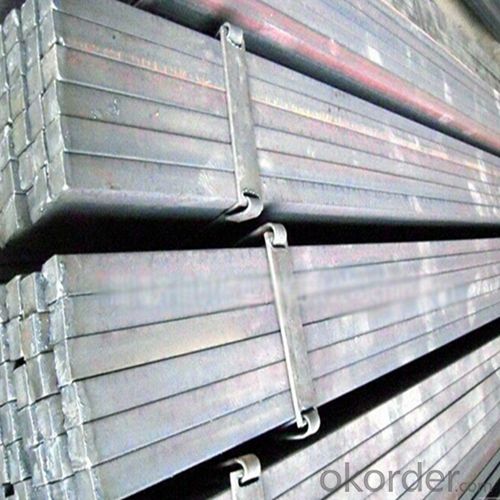

1. Structure of Mild Steel Square Billet description:

Mild steel square billet is a bar with square shaped cross-section. It is special case of equal sides. Before steel products are sold on the market, the steel must first be processed into more functional pieces. Raw steel cannot be of use while in its pure form, thus it has to be cast into shape. The freshly made steel, mild steel square billet is still in the form of a metal bar or rectangle. Small sizes of mild steel square billet are used in ship building.

2. Main Features of Mild Steel Square Billet:

• Grade: Q235

• Type: Mild carbon steel

• A quadrilateral with four equal sides and four right angles.

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Mild Steel Square Billet Images:

4. Mild Steel Square Billet Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①What is the main material?

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: How accurate are steel squares?

- Steel squares are generally considered to be highly accurate measuring tools. Their accuracy depends on the quality of the manufacturing and the precision of the markings on the square itself. High-quality steel squares have precise angles and straight edges, allowing for accurate measurements and squareness checks. However, it is important to note that even the best steel squares may have slight variations due to manufacturing tolerances. To ensure the accuracy of a steel square, it is recommended to check it against a known reference or a precision measuring instrument. This can be done by placing the square against a flat surface and verifying that the edges are parallel and the angles are square. If any discrepancies are found, adjustments can be made or the square can be replaced if necessary. Overall, steel squares are generally reliable and accurate tools for measuring and checking squareness. However, it is always important to verify their accuracy and perform regular maintenance to ensure their continued precision.

- Q: How do you use a steel square to determine cut angles?

- To use a steel square to determine cut angles, you can follow these steps: 1. Place the steel square on the material you want to cut, aligning one edge of the square with the edge of the material. 2. Find the angle you want to cut and locate the corresponding angle on the steel square. The steel square typically has a protractor scale on one of its sides. 3. Once you have located the angle on the steel square, mark the material using a pencil or a scribe along the edge of the square. 4. Double-check the alignment and ensure that the square is securely positioned before making the cut. By using a steel square in this way, you can accurately determine and mark the desired cut angles on your material, ensuring precise and consistent cuts.

- Q: Can a steel square be used for checking the squareness of a countertop?

- No, a steel square is not suitable for checking the squareness of a countertop. Steel squares are typically used for measuring and marking right angles in woodworking and metalworking projects. However, when it comes to checking the squareness of a countertop, specialized tools such as a carpenter's square or a framing square would be more appropriate. These squares are specifically designed for accurately measuring and verifying right angles, making them more reliable for ensuring the squareness of a countertop.

- Q: How do you use a steel square to measure and mark 326.25-degree angles?

- A steel square cannot directly measure or mark 326.25-degree angles as it typically has markings for 90-degree, 45-degree, and 30-degree angles. To measure or mark a 326.25-degree angle, you would need to use a protractor or a specialized angle measuring tool.

- Q: Can a steel square be used for marking out tenon shoulders?

- Yes, a steel square can be used for marking out tenon shoulders. A steel square is a versatile tool that can be used for measuring and marking out precise angles and lines, making it suitable for marking the shoulders of a tenon. Its sturdy construction and accurate measurements ensure a clean and professional result.

- Q: Can a steel square be used for checking the squareness of a window frame corner?

- Indeed, the squareness of a window frame corner can be assessed using a steel square. Carpenters and builders often rely on this tool to guarantee precise right angles. With its 90-degree angle, the steel square enables accurate measurement and verification. By positioning the steel square against the window frame corner, one can effortlessly ascertain whether it is perfectly square or necessitates adjustments. Consequently, the steel square serves as a trustworthy instrument to evaluate the squareness of a window frame corner.

- Q: Can a steel square be used for furniture-making projects?

- Indeed, furniture-making projects can utilize a steel square. Woodworkers and furniture makers frequently employ steel squares to precisely gauge and designate angles, corners, and straight lines. These adaptable tools serve various purposes, including verifying joint squareness, outlining mortise and tenon joints, and guaranteeing accurate cuts and joinery. Due to their durability and ability to yield precise measurements, steel squares prove invaluable in furniture-making endeavors.

- Q: Can a steel square be used for checking the squareness of a picture frame?

- Yes, a steel square can be used for checking the squareness of a picture frame. A steel square is a tool that has a 90-degree angle, making it ideal for measuring right angles. By placing the steel square against the corners of the picture frame, you can easily determine if the frame is perfectly square or if there are any discrepancies. If the frame is not square, adjustments can be made to ensure that the corners are properly aligned and the frame is straight.

- Q: Can a steel square be used for checking the alignment of a wall frame?

- Yes, a steel square can be used for checking the alignment of a wall frame.

- Q: How do you use a steel square to measure board thicknesses?

- To use a steel square to measure board thicknesses, simply place one edge of the square against the board's edge and align the other edge with the opposite side of the board. Then, read the measurement scale on the square to determine the thickness of the board.

Send your message to us

Mild Steel Square Billet for Section Steel Production in Factory Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords