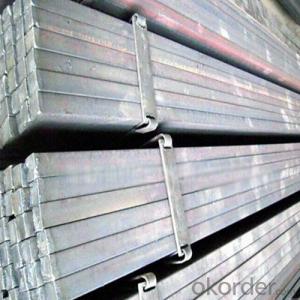

Square Steel Cold Drawn with High Quality for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Cold Drawn with High Quality for Sale:

Diameter:2-500mm

Length:Customized

Quality: High quality stainless steel bar

stainless steel square bar flat steel bar

Stainless Steel bar

Diameter:2-160mm

Length: Customized

Technique | Hot Rolled/Cold Drawn/Peeled |

1.Round bar 1Hot rolled black bar: (5~400x6000mm or according to your requirement. 2Acid round bar: (5~400)x6000mm or according to your requirement. 3Cold drawn bright bar: (1~20x6000mm or according to your requirement. 4)Polishing round bar: (5-400)x6000mm or according to your requests. | |

2. Square bar 1)Hot rolled black bar: (5*5-400*400)x6000mm or according to your requests. 2)Acid square bar: (5*5-400*400)x6000mm or according to your requests. 3)Cold drawn square bar: (1*1-20*20)x6000mm or according to your requests 4)Polishing square bar: (5*5-400*400)x6000mm or according to your requests | |

Diameter± | H9 tolerance can reach the industry standard |

Quality | Our production equipment 24 hours of continuous temperature work, to ensure the unity of the product roundness, elongation, tensile strength and yield strength. Welcome customers to our company to detect the products before shipment. For the customers who are not inconvenient, quality assurance can be laid down in the contract, we will take charge of the returning and shipping fee if there is any problems of the product quality, so it will dismiss any of your worry about our products. |

Package | Standard seaworthy packing(plastic&wooden) or according to the customer's requests |

Delivery time | 7-20days, according to the quantity |

Productivity | 10000 tons/month |

Applications of Square Steel Cold Drawn with High Quality for Sale:

Hot Rolled Steel Rebar Deformed Bar High Quality Made In China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Advantages of Square Steel Cold Drawn with High Quality for Sale:

OKorder's Hot Rolled Steel Rebar Deformed Bar High Quality Made In China are durable, strong, and resist corrosion.

Main Product Features of Square Steel Cold Drawn with High Quality for Sale:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can a steel square be used for fence-building projects?

- Yes, a steel square can be used for fence-building projects. Steel squares are versatile tools that can assist in ensuring accurate angles and measurements during the construction and installation of fences. They can help in marking out precise right angles, checking for levelness and plumbness, and ensuring the correct alignment of posts and rails, making them a valuable tool for fence builders.

- Q: Can a steel square be used for drawing straight lines?

- Yes, a steel square can be used for drawing straight lines. A steel square, also known as a framing square or a carpenter's square, is a versatile tool used in carpentry and other trades. It consists of two arms, one longer than the other, which meet at a right angle. The longer arm usually has measurements marked along its edge, allowing for accurate measurements and angles. To draw a straight line using a steel square, one can align the longer arm of the square with the desired line and hold it securely in place. By using a pencil or a marking tool against the edge of the longer arm, one can then easily draw a straight line. The steel construction of the square ensures its durability and stability, making it a reliable tool for drawing straight lines. However, it is important to note that the accuracy of any straight line drawn with a steel square depends on proper alignment and positioning of the tool. It is recommended to use a level or another straight edge to double-check the accuracy of the line. Additionally, when using the steel square, it is essential to hold it firmly and steady to prevent any unintentional movement that could affect the straightness of the line.

- Q: How does a steel square assist in determining the correct angle for a half-blind dovetail joint?

- A steel square can be a helpful tool in determining the correct angle for a half-blind dovetail joint. This type of joint is commonly used in woodworking to create a strong and aesthetically pleasing connection between two pieces of wood, typically seen in drawers or boxes. To create a half-blind dovetail joint, one side of the joint is visible while the other side is concealed within the wood. The visible side is usually cut at a 90-degree angle to create a neat and clean appearance. The concealed side, however, needs to be cut at an angle that matches the slope of the dovetail pins. This ensures a snug fit and a strong joint. Here's where a steel square comes in handy. A steel square is a flat, triangular-shaped tool with a 90-degree angle. By using the steel square, you can accurately determine the angle needed to cut the concealed side of the joint. First, mark the desired angle on the steel square. This angle should match the slope of the dovetail pins, typically 7 to 9 degrees. Then, place the steel square against the edge of the wood piece, aligning the marked angle with the edge. By holding the square firmly in place, you can now use it as a guide to cut the concealed side of the joint at the correct angle. By using a steel square, you can ensure that the angle of the half-blind dovetail joint is accurate and matches the slope of the dovetail pins. This precision helps in achieving a tight and professional-looking joint, enhancing both the strength and visual appeal of the finished woodworking project.

- Q: What are some alternative tools to a steel square?

- There are various options available as alternatives to a steel square for different tasks. The following are some of these alternatives: 1. Framing Square: In carpentry and framing projects, a larger version of a steel square called a framing square is commonly used. It consists of two arms, one longer and one shorter, forming a right angle. The longer arm usually has measurements and markings for easy angle and length calculations. 2. Combination Square: For measuring, marking, and checking right angles in woodworking and metalworking projects, a versatile tool called a combination square is used. It combines a ruler, a square, and a level. 3. Speed Square: In roofing and carpentry projects, a triangular-shaped tool known as a speed square, rafter square, or triangle square is commonly used. It serves multiple purposes, including measuring and marking angles, determining roof pitches, and acting as a saw guide. 4. Sliding T-Bevel: To transfer and measure angles, a tool called a sliding T-bevel is used. It consists of a handle and a blade that can be adjusted to any desired angle and locked in place. Woodworking and metalworking projects often employ this tool for marking and replicating angles. 5. Angle Finder: An angle finder is a tool used for accurate measurement and transfer of angles. It typically comprises two arms with pivoting joints that allow for easy adjustment and locking. Carpentry, metalworking, and construction projects commonly rely on angle finders. 6. Digital Angle Finder: For working with complex angles or when a high level of accuracy is required, a more advanced version of an angle finder called a digital angle finder is used. It usually has a digital display that provides precise angle measurements. Depending on the specific task, these alternative tools can serve as excellent replacements for a steel square. They offer unique functionalities and features that cater to different needs and preferences.

- Q: How do you use a steel square for making accurate miter cuts?

- Achieving accurate miter cuts with a steel square involves several steps: 1. Ensure that your steel square is clean and free of dirt or debris. This is important for obtaining precise measurements. 2. Position the steel square flat against the material's edge where the miter cut will be made. Make sure it is aligned correctly and that the desired cutting angle is perpendicular to the square. 3. Securely hold the square against the material to prevent any movement or shifting. If necessary, use clamps or a vise to keep the square in place. 4. Use a pencil or marking knife to mark the line where the miter cut will be made. Align the square with the desired angle and trace along its edge to create an accurate guideline. 5. Verify the square's alignment before proceeding. It is crucial to confirm that the square has not moved while marking the line. 6. Carefully follow the marked line using a miter saw or handsaw to make the miter cut. Take your time and make precise cuts to achieve the desired angle. 7. After making the cut, check the accuracy of the miter by fitting the two cut pieces together. They should fit snugly and form a perfect angle. If adjustments are necessary, use sandpaper or a file to refine the cut until the desired fit is achieved. Remember, practice and patience are essential when using a steel square for accurate miter cuts. Over time, you will improve and achieve precise, clean cuts for your woodworking projects.

- Q: How do you use a steel square to mark parallel lines?

- In order to mark parallel lines using a steel square, you will require a flat surface, a pencil or marking tool, and the steel square itself. Begin by placing the steel square on the flat surface, aligning one of its edges with the starting point of the line you wish to mark. Make sure to firmly hold the square against the surface to prevent any movement. Next, take the pencil or marking tool and position it against the inner edge of the square, ensuring that it is perpendicular to the square's edge. Adjust the marking tool's position until it aligns with the desired distance for the parallel line. Once the marking tool is properly positioned, carefully slide the square along the surface while keeping the marking tool against the inner edge of the square. This will generate a straight and parallel line that is equidistant from the original line. Repeat this procedure as necessary to mark multiple parallel lines using the same measurement. Always double-check that the square is correctly aligned and securely positioned against the surface before marking each line to guarantee accuracy and consistency.

- Q: What are the different ways to hold a steel square?

- To hold a steel square, there are various methods to consider based on the specific task and personal preference. Here, we present some commonly used techniques: 1. Finger grip: The most basic and widely used approach involves firmly grasping the steel square with your fingers and thumb, ensuring a secure hold. 2. Palm grip: Some individuals prefer this method for enhanced control and stability. It involves holding the steel square in your palm, with your fingers wrapped around the handle. This grip facilitates greater precision and accuracy during usage. 3. Thumb grip: Another popular technique is to hold the steel square with your thumb on one side of the handle and your fingers on the other side. This grip provides stability and control while keeping your fingers free for other tasks. 4. Hook grip: In specific situations where stability is required, you may need to hang the steel square on an edge or hook it onto a surface. To achieve this, you can hold the square by inserting your fingers through the holes or slots in the handle, creating a grip resembling a hook. 5. Clamped grip: For more intricate tasks such as woodworking or metalworking, securing the steel square in place using clamps or vices can be advantageous. This ensures the square remains fixed, enabling precise measurements and marking. Ultimately, the choice of how to hold a steel square depends on personal comfort, the nature of the task, and the desired level of control and stability. It is crucial to find a grip that allows for safe and effective use of the square.

- Q: How do you use a steel square to determine the angle of a molding cut?

- In order to determine the angle of a molding cut using a steel square, a few simple steps must be followed. Begin by ensuring that the steel square is clean and devoid of any debris or rust, as this will guarantee precise measurements. Next, position the square on the molding's edge, aligning one side of the square with the edge of the molding. Verify that the square is placed in a manner where the other side is perpendicular to the molding's edge. Once the square is appropriately positioned, locate the angle markings on the square. These markings are typically situated on the inside corner of the square, where the two arms meet. Now, carefully observe the angle measurement indicated on the square. This measurement will aid in determining the angle at which the molding needs to be cut. If the angle indicated on the square exceeds 90 degrees, it signifies the necessity for an obtuse angle cut. If the angle is less than 90 degrees, it denotes an acute angle cut. To execute the cut, transfer the angle measurement from the square to your saw or miter box. Set the saw or miter box to the desired angle and meticulously cut the molding along the marked line. Always remember to wear appropriate safety gear, such as goggles and gloves, when working with tools and sharp objects. Prior to making any cuts, double-check your measurements and angle settings to ensure accuracy and precision.

- Q: Can a steel square be used for precise woodworking?

- Yes, a steel square can be used for precise woodworking. Steel squares are commonly used in woodworking for accurate measurements, marking, and checking right angles. They are durable, provide straight edges, and are suitable for various woodworking tasks such as marking lines, checking corners, and ensuring accurate cuts and joints.

- Q: Can a steel square be used for checking the squareness of a table saw fence?

- Yes, a steel square can be used for checking the squareness of a table saw fence. A steel square, also known as a carpenter's square or framing square, is a tool with a right-angle shape that can be used to ensure that the edges and corners of a workpiece or tool are perfectly square. To check the squareness of a table saw fence, simply place the steel square against the fence and align it with the blade of the table saw. If the square is properly aligned, the blade should be perpendicular to the fence, indicating that the fence is square. However, it is important to note that while a steel square can provide a quick and easy way to check squareness, it is always recommended to use a more precise measuring tool, such as a dial indicator or precision square, for accurate results.

Send your message to us

Square Steel Cold Drawn with High Quality for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords