Middle Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

Waterproofing;Sound Insulation;High density;moisture proof;anti-sunk;Strength;Toughess;Anti wet; Nice thin board usage,bendable.

2,Main Features of the (Cement Boards)

Properties:

·100% Non-asbestos

·Density: 1250 to 1500 kg/m3 (+ - 5%)

·Coefficient of thermal expansion: 0.11 kcal/m.hroC

·Bending Strength: over 180 kgf/cm2

·Linear expansion rate: 0.1%

·Water absorption rate: 35%

·Water penetration rate: 0%

·Water content: 8%

·Incombustibility according to CNS 6532 and BS 476

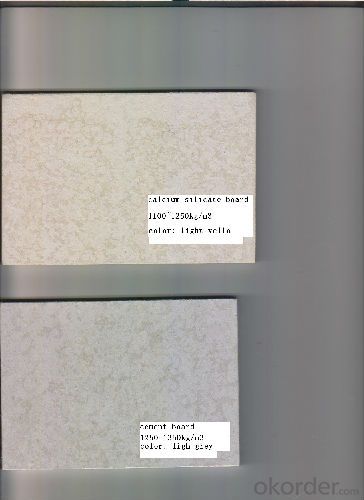

3,(Cement Boards) Images

4,(Cement Boards) Specification

| Standard Data of the Middle Density Firber Cement Board | ||||||||

| Standard Size | 1220X2440mm/1200X2400mm | Max Width | 1250mm | Max Length | 4880mm | |||

| Thickness | 4-30mm | Density | 1.3-1.7g/cm3 | |||||

| Wet Expansion Rate | ≤0.23% | Water Penetration | ≤25% | |||||

| Forst Resistance | No Layer & no cracks after 25 cycles under freezing and thawing | |||||||

| Incombustibility | Incombustible Class A1 | Radioactivity | Decorative materials Class A | |||||

| Flexural Strength | Air dried Condition ≥18 | Water Penetration | Back side without water drop after 24 hours | |||||

| Saturated Condition≥14 | ||||||||

5,FAQ of (Cement Boards)

Application

(1)Cavity Wall for Interior Partition

1.Wet area( restroom,kitchen and basement etc.)

2.High sound insulation requirements area ( pc room,meeting room and hotel etc.)

(2) Light Concrete Grouting Wall

(3) Other Applications

1. Ceiling board

2. Perforated board

3. Aluminum lining boards and insulation barriers for high-speed train

4. Column Coverage

Production Scale and Equipment

We introduced international advanced equipment and technologies. From raw materials preparation to board forming stacking and compressing, autoclaving and destacking are all controlled by strict and efficient production craft. The whole process is full automatic, high efficient and quality stable.

- Q: how can i put tile in my bathroom using thin cement board.so my bathroom floor can be even with my living room floor.

- You have to consider the thresh hold-doorway. Usually it is a strip of marble. The bathroom is considered a wet area so you may not want it even with your living room floor. Blue board is most often the foundation for good tile work.

- Q: our cement board was left out in a rain storm and then was installed under marble tiles. will this be an issue?

- Yes it can, but makes sure its dry before it gets closed off (tiled over)

- Q: Can cement fiber board be attached to fire board?

- Cement fiber board he would have belonged to a1 grade fireproof material, you posted fire board why, money ah

- Q: over the bath tub is durock cement board enough by itself,or it has to be something else under durock...?

- There has to be done more then that. 1st I would check your local codes 1st some say yes some say no. But when you have the wall apart you should insulate and put plastic up. This will do a few things It will deadin the sound and if you ever put in a steamer or anything else the walls will be preped. Plus doing this will not cost you much at all. Maybe 100bucks if that. Its much better to do it now then later Plus if you sell your house Its a good thig to say. Hey if you want to do this or that The walls are ready for whatever you want to do. Im a Plumber for 20yrs and everytime I run into this and I tell them sorry I cant put in a steamer or other things cuz it aint up tp code and so on. So take the extra time and money and do it correct. If you just want to doit quick and not care then use d-rock make sure you do the seams and the CORRECT SCREWS!!! Goodluck

- Q: An exhibition, you can use the cement board to do arc shape of the wall? If so, what about the specific building steps?

- Cement board to do the arc wall, then cut into a long strip of the fight Steps: playing keel cement pressure plate cut the arc to fight arc-shaped shape hanging iron net plaster finishes

- Q: im using a cement backer board why do i need a scratch coat and mesh?

- Sounds like belt and braces to me.

- Q: Do you know that light through the cement? What is the material and how to do it?

- Transparent cement is a widely used with a new light transmission properties of building materials, is composed of fiber and fine grinding cement compounds. The cement is made up of thousands of optical fibers parallel to each other on both sides of the cement block. The proportion of fibers is very low (4%) throughout the cement block. In addition, because the fiber size is very small, so become a cement structure of a collection of components, cement block surface or uniform cement. Transparent cement can be used to build construction installations to build prefabricated blocks and cement boards. As the fiber size is small, so as a new ingredient mixed with the cement together to form a collection. Therefore, the final not only in the cement is mixed with two components of glass fiber only, but in the internal structure and the surface can achieve a balanced effect of new building materials. In theory, the light-permeable cement block can be built with a few meters of thickness of the wall, because the fiber in principle, within 20 meters will not lose any light information. The fiber does not affect the high capacity of the cement, so in these cement blocks can build any load of the building structure. The light-permeable cement block can be produced in a different size, and a heat-insulating layer can be added thereto.

- Q: Help? Do I just lay new thinset on top or what?

- i've got laid some tile, flooring,showers, and a pair tables(greater of the mosaic form). i'm exceedingly beneficial which you're able to desire to apply hardibacker(cement board) purely for showers or kitchen/tub flooring. it somewhat is substantial objective is to evade any air /moisture from seeping up with the aid of the backside ,for this reason inflicting the tiles to interrupt. Hardibacker helps seal all that out. yet i do no longer think of it somewhat is mandatory on your project. you will no longer could difficulty approximately spilled drinks after your table is cured and sealed. The grout is what keeps something from getting below your tiles. be certain you wait a minimum of 24 hours earlier sealing your new tile activity. perhaps look into a tile e book from the library or seem up How-to do -it your self form of web sites for education. stable success!

- Q: The cement is in a three foot hole used with lumber for a hammock which, was too small as it broke off at the base. I've read where other people have dug around the cement to loosen it, but my main problem would be lifting it out once it's loose. Another option I found was using a sledge hammer to break it up but I don't own one. I'm sure I could rent one from my local home improvement store, but thought I'd try this avenue first to see if there were any alternatives.Thanks!

- If there is still wood in the concrete use self-starting bolts and bolt another board across so that after loosening dirt around outside of concrete use rope, chain, or whatever to lift out of hole.

- Q: What is the best thing to do with the top floor of the house?

- Wash the trough with a brush with water Will cf-2000 efficient composite waterproofing agent, live putty-like, with water plugging is to be slightly harder, and then filled into the chiseled slot. Sealed compaction can be. Fill the groove before filling the water. Can be plugged with water immediately after the operation of water plugging. 30 minutes can be only 2 kg pressure seepage. 24 hours can be resistant to 7 kg pressure seepage.

Send your message to us

Middle Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords