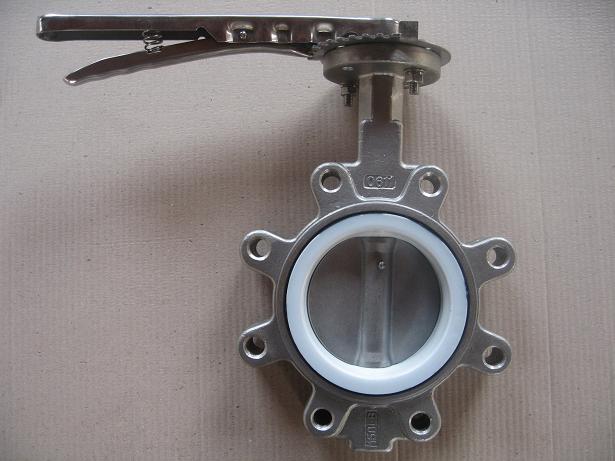

lug type butterfly valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Lug Type butterfly valves

About Product

A butterfly valve consists of body ,stem ,disc , actuator (manual actuator, worm-gear actuator , aerodynamic actuator or electric actuator) , and PTFE butterfly valve can implement the process for turning on turning off and regulating the flow by the circumrotation of stem and disc that is droved by actuators.

1.Simple and compact construction. Small in size and light in weight. Easy transportation, installation and maintenance.

2. Quick 90 degrees on-off operation. Minimized operating torque ,energy saving.

3. Excellent sealing performance with ZERO leakage. Long service life.

4. Wide selection of materials ,applicable for various media..

5. Flow curve tending to straight line. Excellent regulation performance.

- Q: I am working on my riding mower Briggs and Stratton 15.5 OHV. After replacing my headgasket my intake valve did not move when I turned shaft by hand. I took it back apart and believe I have my pushrods positioned correctly but cannot seem to get the rockkers back over the valves and rods. Maybe its because I am a girl and just need to man up but I thought it should be easier. Anyone got any tips?

- Okay, here we go. I have been doing this for 150 years, so I think I know why you are having the problem. The piston must be at Top-Dead-Center (TDC) on the FIRING stroke. Both valves will be what is known as On The Rock. That is or means the push-rods will be resting on the camshaft inside the engine where there is no lift (bottomed). The best way to find this out is to look at the flywheel and see where the magnet is in relation to the ignition coil. The engine actually fires twice (it's just the way it is), but if yo see the magnet on the ignition coil then chances are you are either at TDC on the compression stroke or BDC on the induction stroke. Confused yet? Let's make it easy to tell the difference. When the piston is at TDC the piston will be at the to p of the bore and the magnet will be on the ignition coil. The valve push-rods will be at the same height. This is when you fit the rockers. As you can see there will be two nuts or a single nylock nut that has a nylon insert. If you have the nylock nut then then just tighten the inlet to 0.007 and the exhaust to 0.010. The same applies with the two nut system, except that when you have set the gaps you have to spin the locking nut down and hold the set nut (the first one) and then tighten the other nut down tight to the set nut. But I guess you knew all this, eh. Good to go, eh. I hope I might have been some help. mmalky: 50 years fixing small and large lawnmowers.

- Q: My sprinkler valve I just put in leaks from the top knobs you turn to allow water to pass through to the 3 main pvc pipes. I turn the water on on the main water line, open the little black twisty knobs to allow the water to pass through to the irrigation lines, but water leaks out through all 3 black twisty knobs. What do I need to do?!?!?!

- I have been given the equivalent line from our water application while the strain valve broke and blew up our water softener it is the 1st concern on the line from their tension regulator. fortuitously, it has a lifetime insurance yet their plumber urged me that it incredibly was once the duty city on account that of the strain regulator which they admitted to being at fault as quickly as they replaced it.

- Q: I just got a new set of tired 2 months ago. The last 3 weeks I've had a separate tire go flat (3 in total). The last 3 the repair company said they were caused by cracked valve stems. So after the 3rd time it happened they replaced all valve stems on each tire. Now today I just got a 4th flat. That's 1 each week for the past 4 weeks. I'm taking into the shop this afternoon for them to inspect the tire. I suspect they will say it's again the valve stem. Any help on what I can do or what to say or ask to get them to fix the problem instead of just putting another bandaid on it? I'm very concerned about my safety and it really sucks that everytime i get into my car, I have to wonder, am i going to get a flat tire today...

- Any reputable tire shop will install new valve stems when mounting new tires. This really sounds like somebody is messin with you. Anyone else in your area having similar problems?

- Q: I just bought a brand new rain bird sprinkler valve with flow control and when I turn the valve on automatically or manually it makes a loud sound that resembles a muted horn and when I close it, it makes the same sound but thumps at the end. Is this normal? Or do I need to get a new valve?

- Provided you are talking about the valve that controls flow from the constant on of water to the sprinklers, that also cuts it off, the turning on is a groaning of the built up pressure (normal) releasing into the sprinkler line. The thump only occurs at the end when you close it because it's slowly cutting off the pressure. Its more pronounced in the sprinkler valves because you are dealing with greater pressure than say when you turn on a sink or hose, in fact you can nearly mimic a more muffled version of the sound by using a hose, and kinking it or using a nozzle head. Having installed 20+ of these working with my Dad on his rental properties, I can guarantee they are not silent. Unless water is spraying all over the place, I'm 98% positive its a perfectly functioning valve.

- Q: i went to the heart doc today to get the results from an echocardiogram and he told me i had two leakages in one of the valves of my heart. i dont know why, but i didnt even bother to ask him exactly what that meant because he told me it was nothing to worry about. can anyone tell me more about this?

- What okorder /

- Q: I gotta 89 Crx si. Just wondering if you could put on a blow off valve and it work without it boosted

- Simply put...No...If you mount it on a cold air intake, you will intake air from where you mount it, and most likely throw off your MAFS and make your car run poorly

- Q: what are the factors should be know to select a control valve for specified application

- nan

- Q: Is there any application usuage of ball valve in comparison,most engineers opinion is as Valve size get reduces in reduced port.Other than this what paramteres decides in selection of either of one

- W.W. Grainger out of Chicago ships all over the world, also McMaster-Carr Supply.

- Q: 1. Why is there an exaust valve. Isnt it only a port. Where do the gases that go into the exaust valve go?2. How does air enter the intake valve. If you look at a push rod diagram, you cant see where the air is enteringCan someone explain to me the valve concept

- Hey mechanic wannabe, The intake valve opens, the piston moving downward pulls the fuel mixture into the combustion chamber, the fuel explodes under pressure caused by the piston rising and both valves remain closed. When the piston comes back up the exhaust valve opens and all the burnt fuel leaves the combustion chamber and goes down the exhaust pipes until blown out the end of the exhaust system.

- Q: i have a 04 kia sadona i have been having issues with the van overheating someone told me to open the bleeder valve and let it drain then refill leave the valve open and if i see bubbles in the radiator than its a blown head gasket. is this true? is there a bleeder valve on this and if so where is it located? its not on the thermostat housing i allready replaced the thermostat.

- Remove the radiator cap when cold and run the engine. Have someone rev the engine while the transmission is in park (with the parking brake ON), and you watch in the top of the radiator for bubbles. It may take a few seconds from the time they rev till the bubbles rise to the top.

Send your message to us

lug type butterfly valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords