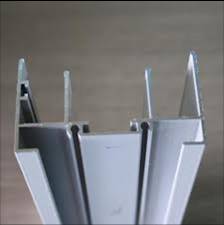

Large Aluminum Extrusion Profiles for Window Frame

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Item: | aluminium window and door profile |

Material: | 100% alloy :6063-T5,6061-T6,6463-T5,7075-T6,6082,5052,2024,7005,6013,7020 etc. |

Size: | 3m-6m or customized size |

Application | Furniture, windows & doors, decorations ,industry, construction etc. |

Colors: | Anodized, wood grain,powder coating, anodised polished and brushed, electrophoresis, flurocarbon powder coated etc. |

MOQ: | 500KG for each profile |

OEM service | based on customer designed drawings or samples |

Certification | ISO:9001, SONCAP , BV Certificate or customers’ Certificate Available |

Packing Detail | (1)Inside : packed with plastic protective film to protect each profile |

(2)Outside:packed with waterproof kraft paper | |

Delivery time: | (1)Die Developing and Sample test : 12-18days . |

(2)Production duration:25-30days after sample is confirmed by Buyer. | |

Payment term: | T/T, 30% down payment while balance shall be paid off before delivery. |

Settlement : | Final payment shall be based on final actual physical weighing. |

Capacity: | 2400-3000 Metric tonnes per month. |

Guarantee | Surface color is able to sustain for 10~20 years for indoor using. |

Port: | FOB Shenzhen, Guangzhou, Foshan |

Strong resistance corrosion property, effectively prevent acid, alkali, and salt etc.

Smooth and subtle, vivid, bright, and magnificent appearance

Alloy: 6063

Finish: anodizing, electrophoretic coating, powder coating, wood effect etc according to customers’ need

Standard package: suitable for long ocean transporting

OEM&ODM is welcome

Last for life time

- Q: What precautions should be taken while handling aluminum profiles to ensure safety?

- <p>When working with aluminum profiles, it's important to take several safety measures. Always wear appropriate personal protective equipment (PPE), including safety glasses to protect your eyes from flying debris, gloves to protect your hands, and a dust mask to prevent inhalation of dust particles. Ensure that the work area is well-ventilated to avoid inhaling aluminum dust. Use proper tools for cutting and shaping aluminum profiles to minimize the risk of injury. Keep the work area clean and free from clutter to prevent tripping hazards. Be cautious when handling sharp edges and ends of cut aluminum profiles. Lastly, be aware of the weight of the aluminum profiles to avoid back injuries when lifting.</p>

- Q: How do aluminum profiles compare to plastic profiles?

- Aluminum profiles generally offer greater strength, durability, and stability compared to plastic profiles. They can withstand higher loads and have higher resistance to heat, chemicals, and UV radiation. Additionally, aluminum profiles provide more design flexibility, as they can be easily machined, welded, and anodized to achieve desired shapes and finishes. However, plastic profiles are often more cost-effective and lighter in weight, making them suitable for certain applications where strength and rigidity are not critical. Ultimately, the choice between aluminum and plastic profiles depends on the specific requirements and constraints of the project.

- Q: Are aluminum profiles suitable for sports equipment?

- Sports equipment can be made using aluminum profiles, as they are lightweight and durable. Aluminum has a high strength-to-weight ratio, making it perfect for applications that require strength without excessive weight. Various sports equipment, including bicycles, golf clubs, baseball bats, tennis rackets, and even sports stadiums and arenas, commonly use aluminum profiles. The lightweight nature of aluminum allows athletes to handle the equipment easily, leading to better performance and less fatigue during sports activities. Moreover, aluminum's durability ensures that the equipment can endure intense use and last longer. The versatility of aluminum profiles also makes them suitable for sports equipment. They can be easily shaped, molded, and manipulated into different designs to meet specific performance requirements. This flexibility enables manufacturers to create equipment with desired characteristics, such as improved aerodynamics, better balance, or enhanced shock absorption. Furthermore, aluminum profiles have excellent corrosion resistance, which is especially crucial for sports equipment that may be exposed to moisture, sweat, or harsh environmental conditions. This property guarantees that the equipment remains functional and maintains its performance over time. In conclusion, aluminum profiles are a suitable choice for sports equipment because of their lightweight, durable, and versatile nature. With their high strength-to-weight ratio, they contribute to improved performance, reduced fatigue, and extended equipment lifespan.

- Q: Fenglv aluminum material how ah? What aluminum materials do you use for windows and doors?

- Domestic aluminum quality is about the same, mainly you installed in the window accessories, is the key to the life of the service, recommend several brands Bar Reid Jan Ron Lixin spring is not recommended, quality is not very rely on live

- Q: Is it possible to utilize aluminum profiles for constructing exterior railings and staircases?

- <p>Yes, aluminum profiles can be used for exterior railings and staircases. They are known for their durability, resistance to corrosion, and low maintenance requirements, making them ideal for outdoor applications. Aluminum's strength and lightweight properties also contribute to its suitability for these structures. However, it's important to ensure that the aluminum is of high quality and properly treated to withstand weather conditions and ensure longevity.</p>

- Q: This question asks about the various uses of aluminum profiles in the construction of buildings.

- <p>Aluminum profiles have a wide range of applications in building construction due to their strength, durability, and lightweight properties. They are used in window and door frames, curtain walls, and structural glazing systems for their high strength-to-weight ratio and resistance to corrosion. Additionally, aluminum profiles are utilized in the construction of balconies, handrails, and stairways for their ability to withstand harsh weather conditions. They are also employed in the fabrication of modular building systems and prefabricated components, offering ease of assembly and design flexibility. Furthermore, aluminum profiles are used in the construction of solar panel mounting systems and facades due to their thermal conductivity and ability to support heavy loads.</p>

- Q: Are aluminum profiles suitable for outdoor sign applications?

- <p>Yes, aluminum profiles are commonly used for outdoor signage due to their durability, resistance to corrosion, and lightweight properties. They can withstand various weather conditions without rusting or fading, making them an ideal material for long-lasting outdoor signs. Aluminum profiles can be easily cut, shaped, and assembled, offering flexibility in design and functionality.</p>

- Q: What are the benefits of using aluminum profiles in interior design?

- There are several benefits of using aluminum profiles in interior design. Firstly, aluminum profiles are highly versatile and can be used in a wide range of applications. They can be easily customized and fabricated to fit different design requirements. Whether you are designing a modern, minimalist space or a traditional, ornate interior, aluminum profiles offer a flexible solution. Secondly, aluminum profiles are lightweight yet durable, making them an ideal choice for interior design. They are resistant to corrosion, moisture, and temperature changes, ensuring a long lifespan. This durability also means that aluminum profiles require minimal maintenance, saving both time and money in the long run. Another benefit of using aluminum profiles is their aesthetic appeal. They come in a variety of finishes, colors, and textures, allowing designers to achieve their desired look and feel. Aluminum profiles can be anodized, powder-coated, or polished, giving them a sleek and modern appearance. They can also be designed to mimic other materials, such as wood or stainless steel, while offering the added benefits of aluminum. Additionally, aluminum profiles offer excellent thermal and acoustic insulation properties. They can help regulate temperature and reduce noise levels, creating a more comfortable and peaceful environment. This is especially beneficial in areas where soundproofing or energy efficiency is required, such as offices, hotels, or residential spaces. Lastly, aluminum profiles are eco-friendly and sustainable. Aluminum is a highly recyclable material, and using aluminum profiles in interior design helps reduce waste and minimize environmental impact. Moreover, aluminum profiles can contribute to energy efficiency by allowing natural light to enter a space, reducing the need for artificial lighting during the day. In conclusion, the benefits of using aluminum profiles in interior design are versatility, durability, aesthetic appeal, thermal and acoustic insulation, and sustainability. These qualities make aluminum profiles a popular choice among designers and architects looking to create functional and visually appealing spaces.

- Q: Are aluminum profiles suitable for use in furniture fittings and accessories?

- Yes, aluminum profiles are indeed suitable for use in furniture fittings and accessories. Aluminum is a versatile material that offers several advantages for furniture applications. Firstly, aluminum profiles are lightweight, making them easy to handle and install. This is particularly beneficial for furniture fittings and accessories that may require frequent adjustments or movements. Additionally, aluminum profiles are highly durable and resistant to corrosion, ensuring a long lifespan for furniture fittings and accessories. This makes them suitable for both indoor and outdoor furniture, as they can withstand various environmental conditions without deteriorating. Aluminum is also highly customizable, allowing for a wide range of design options. It can be easily shaped, cut, and welded into various forms and sizes, enabling furniture designers to create unique and aesthetically pleasing fittings and accessories. Moreover, aluminum profiles are low-maintenance and easy to clean, making them ideal for furniture applications. They can be easily wiped down or washed without the risk of damage or degradation. Furthermore, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, meaning that it can be reused indefinitely without losing its properties. Using aluminum profiles in furniture fittings and accessories contributes to a more sustainable and eco-friendly design approach. Overall, the combination of lightweight, durability, customization options, low-maintenance, and sustainability makes aluminum profiles a suitable choice for use in furniture fittings and accessories. They offer numerous benefits and can enhance the functionality, aesthetics, and longevity of furniture pieces.

- Q: How do you ensure proper electrical grounding with aluminum profiles?

- In order to achieve proper electrical grounding with aluminum profiles, it is necessary to follow a few essential steps. To begin with, it is crucial to ensure the cleanliness and freedom from dirt, dust, or oxidation of all aluminum profiles. This can be accomplished by utilizing an appropriate cleaning agent or solvent to eliminate any contaminants that may impede the grounding process. Subsequently, the utilization of conductive hardware, such as grounding clips or brackets specifically designed for aluminum profiles, can enable the attainment of proper electrical grounding. These hardware components must be securely affixed to the aluminum profiles to establish a dependable electrical connection. Moreover, establishing a robust electrical connection between the aluminum profiles and the grounding system is of utmost importance. This can be accomplished by employing copper or aluminum grounding conductors that are appropriately sized and firmly connected to both the aluminum profiles and the grounding system. Additionally, it is essential to conduct regular inspections of the grounding system to ensure its effectiveness. This may involve scrutinizing for any loose connections, indications of corrosion, or damage to the grounding conductors. Any identified issues should be promptly addressed and repaired to maintain proper electrical grounding. Lastly, it is advisable to consult with a qualified electrician or engineer who specializes in electrical grounding when dealing with aluminum profiles. They can offer specific guidance and guarantee compliance with pertinent electrical codes and standards to ensure the proper and safe grounding of the system.

Send your message to us

Large Aluminum Extrusion Profiles for Window Frame

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords