Laminated Aluminum Steel Sheets - AA1100 D.C Quality Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA1100 D.C Quality Used for Construction Description

Aluminum Sheets AA1100 D.C Quality Used for Construction, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been high weather resistance \anti scratch anticorrosion \ subtle edges and elegant appearance \ easy processing and installation\ high brightness and hardness.

2.Main Features of Aluminum Sheets AA1100 D.C Quality Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

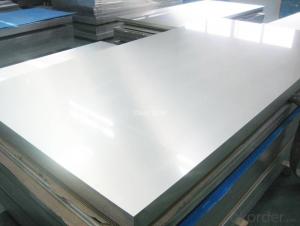

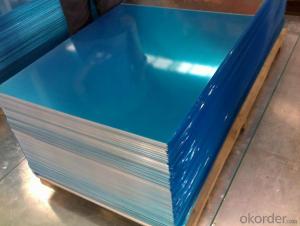

3.Aluminum Sheets AA1100 D.C Quality Used for Construction Images

4.Aluminum Sheets AA1100 D.C Quality Used for Construction Specification

Alloy | AA1100 |

Temper | H14, H16, H18, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1100 D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1100 D.C Quality Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1100 D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can the aluminum sheets be used for manufacturing medical equipment?

- Medical equipment can be manufactured using aluminum sheets, as they possess several properties that make them appropriate for this purpose. Aluminum is widely utilized in various industries, including healthcare, due to its versatility. To begin with, aluminum is both lightweight and durable, which is advantageous for the production of portable medical devices. This characteristic facilitates the handling and transportation of equipment, particularly for healthcare professionals who may need to move them frequently. Additionally, aluminum exhibits exceptional resistance to corrosion, rendering it suitable for medical applications where cleanliness and hygiene are paramount. It can endure disinfection processes without suffering any deterioration, thus ensuring the longevity of the equipment. Moreover, aluminum can be easily sterilized, which is crucial for medical equipment. It can withstand high-temperature sterilization methods, such as autoclaving, without experiencing any detrimental effects on its structural integrity. Furthermore, aluminum possesses excellent heat and electricity conduction properties. These attributes are beneficial for medical equipment that requires efficient heat dissipation or electrical conductivity, such as surgical instruments or diagnostic tools. Furthermore, aluminum is non-toxic, making it safe for medical use. It does not release harmful substances, guaranteeing the absence of health risks to both patients and healthcare professionals. In conclusion, aluminum sheets are indeed suitable for the manufacturing of medical equipment due to their lightweight nature, durability, corrosion resistance, sterilization capabilities, thermal and electrical conductivity, as well as their non-toxicity. These properties make aluminum an appropriate choice for various medical applications, thereby contributing to the advancement of healthcare technology.

- Q: Can aluminum sheets be used in the aerospace industry?

- Indeed, the aerospace industry does employ aluminum sheets. Aluminum, being a lightweight material with a remarkable strength-to-weight ratio, is highly favored for numerous aerospace purposes. Its usage is prevalent in the manufacturing of aircraft structures, including fuselages, wings, and panels. The adoption of aluminum sheets in the aerospace sector offers several advantages, encompassing diminished fuel consumption due to weight reduction, enhanced maneuverability, and heightened payload capacity. Furthermore, aluminum showcases excellent resistance to corrosion, a vital trait for aircraft operating in harsh environmental conditions. All in all, the aerospace industry extensively relies on aluminum sheets, owing to their advantageous properties and exceptional performance.

- Q: Are 101 aluminum sheets suitable for outdoor applications?

- Yes, 101 aluminum sheets are suitable for outdoor applications.

- Q: Can aluminum sheets be recycled?

- Yes, aluminum sheets can be recycled. Aluminum is one of the most commonly recycled materials in the world because it can be recycled indefinitely without losing its quality. Recycling aluminum sheets involves melting them down to their original state and then shaping them into new sheets or other aluminum products. This process requires significantly less energy compared to producing aluminum from raw materials, making recycling aluminum sheets an environmentally sustainable option.

- Q: Can aluminum sheets be welded?

- Yes, aluminum sheets can be welded. Aluminum is a versatile material that can be easily welded using various welding techniques such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Gas Metal Arc Welding (GMAW). However, welding aluminum requires special considerations compared to other metals due to its unique properties. Aluminum has a low melting point and high thermal conductivity, which means that it requires a higher heat input and faster welding speed compared to other metals. Additionally, aluminum oxide can form quickly on the surface, making it necessary to remove this oxide layer before welding. Specialized welding techniques, such as using alternating current in TIG welding or using a spool gun in MIG welding, are often employed to ensure proper weld quality. Overall, with the right techniques and equipment, aluminum sheets can be successfully welded, making it a popular choice in various industries such as automotive, aerospace, and construction.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: Is it possible to use aluminum sheets for indoor purposes?

- <p>Yes, aluminum sheets can be used for indoor applications. They are commonly used in interior design for their durability, lightweight, and resistance to corrosion. Aluminum sheets are often utilized in the construction of furniture, decorative panels, and even as a material for interior walls and ceilings. Their ease of maintenance and ability to be recycled make them an environmentally friendly option for indoor use.</p>

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- You should have a small metal plate that is riveted into the rear transom that will tell you what the max. capacity, persons and weight. If this is absent, I would answer the question by saying that if your boat is of the John boat variety, (square front end) and pretty shallow sides, I would think twice about 2 large people that weigh 225+. If your boat is of the deep-V variety with deeper sides, then two people with gear would probably be fine. Any way you look at it, a 10 boat is a maximum of twp persons.

- Q: Can aluminum sheet be used for food contact applications?

- Yes, aluminum sheet can be used for food contact applications. Aluminum is a safe and commonly used material for food packaging and cooking utensils due to its non-toxic properties, resistance to corrosion, and ability to maintain food quality and freshness.

- Q: Are the aluminum sheets suitable for manufacturing power distribution panels?

- Yes, aluminum sheets are suitable for manufacturing power distribution panels. Aluminum is a lightweight and durable material with excellent electrical conductivity, making it ideal for use in power distribution systems. Additionally, it is highly resistant to corrosion, which is crucial for ensuring the longevity and reliability of the panels.

Send your message to us

Laminated Aluminum Steel Sheets - AA1100 D.C Quality Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords