Sheets of Aluminum AA1050 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA1050 D.C Quality Used for Construction Description

Aluminum Sheets AA1050 D.C Quality Used for Construction, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been high weather resistance \anti scratch anticorrosion \ subtle edges and elegant appearance \ easy processing and installation\ high brightness and hardness.

2.Main Features of Aluminum Sheets AA1050 D.C Quality Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

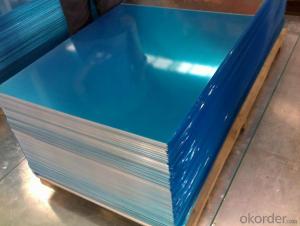

3.Aluminum Sheets AA1050 D.C Quality Used for Construction Images

4.Aluminum Sheets AA1050 D.C Quality Used for Construction Specification

Alloy | AA1050 |

Temper | H14, H16, H18, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1050 D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1050 D.C Quality Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1050 D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What specific criteria or standards must be met when utilizing recycled aluminum in construction?

- <p>Recycled aluminum products used in construction projects must meet specific requirements to ensure safety, durability, and compliance with building codes. These include adherence to ASTM standards for recycled aluminum alloys, such as ASTM B601 for ingots and ASTM B209 for rolled or cold finished products. The recycled aluminum must also have consistent mechanical properties and corrosion resistance comparable to virgin aluminum. Additionally, the products should be free from contaminants that could compromise structural integrity. It's crucial to verify the source and processing methods of recycled aluminum to ensure it meets these standards before use in construction.</p>

- Q: Can aluminum sheets be used for heat sinks?

- Yes, aluminum sheets can be used for heat sinks. Aluminum has excellent thermal conductivity properties, making it an ideal material for transferring heat away from electronic components. Aluminum sheets can be formed into various shapes and sizes to maximize heat dissipation. They are commonly used in applications such as computer processors, LED lights, and power electronics, where efficient heat dissipation is crucial for maintaining optimal performance and preventing overheating. Additionally, aluminum sheets are lightweight and cost-effective, making them a popular choice for heat sink applications.

- Q: Can the aluminum sheets be used for manufacturing light reflectors?

- Yes, aluminum sheets can be used for manufacturing light reflectors. Aluminum is a highly reflective metal and is commonly used in various industrial applications, including the production of light reflectors. Its high reflectivity allows it to efficiently redirect and amplify the light, making it an ideal material for manufacturing light reflectors for applications such as lighting fixtures, automotive headlights, solar panels, and photography equipment. Additionally, aluminum sheets are lightweight, durable, and corrosion-resistant, which further enhances their suitability for this purpose.

- Q: So my new farrier comes out tomorrow and charges $20 more for aluminum shoes and I was wondering why that is? Is one better than the other? My horse is a TB hunter jumper. Tell me what you think :)

- Unless you have a specific reason for aluminum, the steel is better. It is more rigid, and supplies more support to the hoof wall. The aluminum bends if the horse steps on something, stressing the hoof wall. I used them for an OTTB who had weak, shelly hooves in front. He threw shoes like second graders throw spitballs... and when a steel shoe would come off, so would half his hoof wall. I switched to aluminum; the smaller nails stressed the hoof less, and the light weight put less stress on the nails. He still threw the shoes, but his hoof wall stayed intact - a great improvement. I evented and hunter paced this horse in these shoes. They wore pretty well, and I had them reset many times. I din't use the racing plates (even lighter and thinner), but got regular shoes made from aluminum. However, unless you have a similar hoof problem, I'd stick with steel. Edit: they're more expensive because aluminum costs more, and he can't buy them in bulk because fewer people use them. They're also harder to put on properly, because the aluminum nails bend really easily. They can be harder to shape, again because they bend easily and if you're used to bending steel, you have to develop the touch for it.

- Q: How much is the aluminum plate with a thick 2mm 1000*2000? Thanks

- (current aluminium ingot price is about: 15000 yuan / ton, plus board processing fee 2000/ tons, =18000 yuan / ton)2.71*3mm* aluminium plate price 18 yuan / kilogram, =146.34 yuan / square.2MM*2.71* price 18 yuan =97.26 yuan / square.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more).

- Q: I have heard that consuming aluminum can increase your risk for Alzheimer's later in life.Knowing this, would it increase my risk to eat sweet potatoes cooked in aluminum foil?Even if there is a negligible risk, I still want to know for curiosity reasons.Thank You

- Don't eat the foil. The only potentially direct connection to Alzheimers with aluminum was where aluminum dust was inhaled in an industrial setting over several years and the person was diagnosed with Alzheimer's and had high amounts of neurotoxic aluminum in his brain.

- Q: Explain the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with several options to enhance their appearance, durability, and functionality. These include: 1) Anodizing, which creates a protective oxide layer, 2) Powder coating, offering a wide range of colors and textures, 3) Liquid painting, for a smooth, painted finish, 4) Laminating, which bonds a protective film to the surface, 5) Electrolytic coloring, resulting in a variety of colors, 6) PVD (Physical Vapor Deposition), for a high-quality, durable finish, and 7) Thermal spraying, applying a coating to improve wear resistance. Each method serves different purposes and has its advantages and limitations.</p>

- Q: What are the typical thicknesses of aluminum sheets?

- The specific application and industry requirements can cause variations in the typical thicknesses of aluminum sheets. Nevertheless, there are several standard thicknesses commonly used, including 0.025", 0.032", 0.040", 0.050", 0.063", 0.080", 0.090", 0.100", 0.125", and 0.190" inches. These thicknesses find application in diverse industries like construction, automotive, aerospace, and manufacturing. It is worth mentioning that aluminum sheets can be tailored to meet precise thickness specifications for specialized applications.

- Q: Can 101 aluminum sheets be purchased in small quantities or only in bulk?

- Aluminum sheets can typically be purchased in both small quantities and bulk, depending on the supplier and their policies. It is advisable to check with the specific supplier to determine the availability of purchasing 101 aluminum sheets in small quantities.

- Q: What are the typical uses or applications for 101 aluminum sheets?

- 101 aluminum sheets are commonly used in a variety of applications due to their unique properties. Some typical uses for 101 aluminum sheets include: 1. Automotive industry: 101 aluminum sheets are widely used in the automotive industry for manufacturing vehicle bodies, panels, and other components. Their lightweight nature, corrosion resistance, and high strength-to-weight ratio make them ideal for improving fuel efficiency and reducing overall vehicle weight. 2. Construction industry: These aluminum sheets are extensively used in construction projects for roofing, cladding, and facades. They provide excellent durability, weather resistance, and easy formability, making them suitable for various architectural applications. 3. Packaging industry: 101 aluminum sheets are commonly used in the packaging industry for manufacturing cans, containers, and foils. Their malleability and ability to retain the freshness and quality of food make them a preferred choice for packaging perishable goods. 4. Electrical industry: Due to their excellent conductivity and low electrical resistance, 101 aluminum sheets are frequently used in the electrical industry for manufacturing power transmission lines, bus bars, and electrical enclosures. They offer superior heat dissipation properties, making them ideal for applications requiring efficient heat transfer. 5. Marine industry: The corrosion-resistant properties of 101 aluminum sheets make them suitable for marine applications. They are often used in boat building, shipbuilding, and offshore structures, as they can withstand the harsh saltwater environment without significant degradation. 6. Aerospace industry: 101 aluminum sheets find extensive use in the aerospace industry for manufacturing aircraft components such as wings, fuselages, and structural parts. Their lightweight nature and high strength make them crucial for reducing the overall weight of aircraft and increasing fuel efficiency. 7. Household appliances: These aluminum sheets are commonly used in the manufacturing of household appliances like refrigerators, air conditioners, and cookware. Their thermal conductivity, durability, and resistance to corrosion make them suitable for various applications in the home. Overall, 101 aluminum sheets have a wide range of uses and applications across various industries due to their exceptional properties, including lightweight, corrosion resistance, durability, and formability.

Send your message to us

Sheets of Aluminum AA1050 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords