Aircraft Grade Aluminum Sheets AA8006 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA8006 D.C Quality Used for Construction Description

Aluminum Sheets AA8006 D.C Quality Used for Construction, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been high weather resistance \anti scratch anticorrosion \ subtle edges and elegant appearance \ easy processing and installation\ high brightness and hardness.

2.Main Features of Aluminum Sheets AA8006 D.C Quality Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

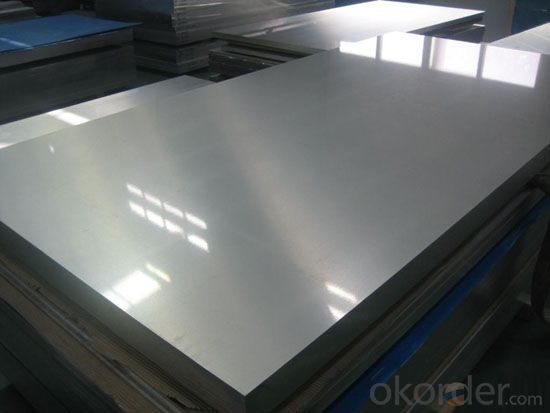

3.Aluminum Sheets AA8006 D.C Quality Used for Construction Images

4.Aluminum Sheets AA8006 D.C Quality Used for Construction Specification

Alloy | AA8006 |

Temper | H14, H16, H18, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA8006 D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA8006 D.C Quality Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA8006 D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What are the different methods for perforating aluminum sheets?

- There are several different methods for perforating aluminum sheets, each with its own advantages and applications. Some of the most common methods include: 1. Punching: Punching is one of the most traditional methods for perforating aluminum sheets. It involves using a punch and die set to create holes in the material. This method is efficient and cost-effective for producing simple hole patterns and is commonly used in industries such as automotive and construction. 2. Laser cutting: Laser cutting is a precise and versatile method for perforating aluminum sheets. It uses a high-powered laser beam to vaporize or melt the metal, creating intricate and complex hole patterns. This method is highly accurate, fast, and suitable for a wide range of applications, including decorative and functional perforations. 3. Waterjet cutting: Waterjet cutting is another popular method for perforating aluminum sheets. It uses a high-pressure jet of water mixed with abrasive materials to erode the metal and create holes. Waterjet cutting is known for its ability to cut through thick aluminum sheets and produce clean and precise edges. It is commonly used in industries such as aerospace and architecture. 4. Rotary perforating: Rotary perforating involves using a rotating cylindrical tool with sharp blades or teeth to perforate aluminum sheets. This method is ideal for producing continuous perforations or creating patterns that require curved or irregular hole shapes. Rotary perforating is commonly used in applications such as filtration systems and acoustic panels. 5. Pressing: Pressing, also known as embossing or stamping, is a method that involves pressing a patterned die into an aluminum sheet to create raised or sunken areas. These areas can act as perforations, providing aesthetic appeal or functional applications such as slip resistance. Pressing can be achieved using hydraulic or mechanical presses and is commonly used in industries such as architecture and interior design. It is worth noting that the choice of perforation method depends on various factors, including the desired hole pattern, material thickness, production volume, and budget. Consulting with a perforation specialist can help determine the most suitable method for a specific application.

- Q: How do you prevent scratches during transportation of aluminum sheets?

- To minimize the occurrence of scratches when transporting aluminum sheets, there are several steps that can be taken: 1. Adequate packaging: It is important to securely package the aluminum sheets using suitable materials like bubble wrap, foam, or cardboard. This will offer cushioning and protection against external impacts. 2. Application of protective layers: Inserting paper or plastic film between individual sheets will prevent direct contact and minimize the risk of scratching. 3. Secure stacking: When loading the aluminum sheets onto transportation vehicles, ensure they are stacked securely to prevent any movement or shifting during transit. This can be achieved by using appropriate strapping or palletizing techniques. 4. Gentle handling: Properly train personnel involved in the transportation process to handle the aluminum sheets with care. They should avoid dragging or sliding them against rough surfaces that could cause scratches. 5. Avoid contact with sharp objects: Take measures to ensure that the aluminum sheets do not come into contact with sharp objects or edges. This can be accomplished by keeping them separate from other materials or using protective covers. 6. Regular inspections: Regularly inspect the aluminum sheets during transportation to identify any potential scratches or damages. If any are discovered, immediate action should be taken to prevent further harm. By implementing these preventive measures, the likelihood of scratches occurring during the transportation of aluminum sheets can be significantly reduced. This will ensure that the sheets are delivered in optimal condition to their destination.

- Q: Can the aluminum sheets be used for manufacturing light reflectors?

- Certainly! Aluminum sheets possess the potential to be utilized in the fabrication of light reflectors. Due to its remarkable reflectivity, aluminum is a frequently employed metallic substance across diverse industrial fields, encompassing the creation of light reflectors. Its exceptional reflectivity facilitates the efficient redirection and intensification of light, rendering it an impeccable material for manufacturing light reflectors for a range of purposes, such as illuminating fixtures, automotive front lights, solar panels, and photographic apparatus. Moreover, the lightweight nature, durability, and resistance to corrosion exhibited by aluminum sheets further augment their aptness for fulfilling this objective.

- Q: i've been looking at stove top espresso coffee makers and they are all made of either aluminum or stainless steel. so i wonder is one metal any better than the other as far as coffee makers go? i thought before i actually buy one i'd like to hear from you - do you have a stove top espresso maker? what metal is it and what do you think of it? looking forward to reading your thoughts - thanks everyone!cheers!

- stainless steel is heavier and holds onto heat longer its also non-reactive aluminum can react to acids, changing flavors, and coffee has acids, so this could affect the taste.

- Q: Can aluminum sheets be used for elevator panels?

- Yes, aluminum sheets can be used for elevator panels. Aluminum is a versatile and durable material that is commonly used in construction and architectural applications, including elevator interiors. It offers several advantages such as being lightweight, corrosion-resistant, and easy to clean. Aluminum panels can be customized to fit the specific design requirements of elevator interiors and can be finished with different surface treatments or coatings to enhance their appearance and durability. Additionally, aluminum is a sustainable material as it is highly recyclable, making it an environmentally-friendly choice for elevator panels.

- Q: Are aluminum sheets suitable for industrial machinery?

- Yes, aluminum sheets are suitable for industrial machinery due to their high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. Additionally, aluminum is easy to fabricate, making it a popular choice for various applications in the industrial sector.

- Q: What are the different grades of aluminum sheets?

- In the market, a variety of aluminum sheet grades can be found, each having its own unique properties and uses. Some commonly used grades are 3003, 5052, and 6061. Grade 3003, a non-heat treatable alloy, displays high resistance against corrosion. It finds its application in scenarios where corrosion resistance is crucial, such as packaging, cooking utensils, and chemical equipment. Grade 5052, also non-heat treatable, offers exceptional corrosion resistance along with strength and durability. This makes it suitable for marine applications, transportation equipment, and architectural purposes. Grade 6061, a heat treatable alloy, combines good corrosion resistance with high strength. It is extensively used in structural applications like aircraft components, automotive parts, and construction materials. In addition to these grades, there are specialized aluminum alloys like 2024, 7075, and 5083, catering to specific properties required in particular industries or applications. To ensure the right grade of aluminum sheet for your project, it is crucial to consider its specific requirements, as each grade possesses its own strengths and limitations. Seeking advice from a knowledgeable supplier or expert can assist in determining the most suitable grade for your needs.

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces.

- Q: It seemed in my experiment that aluminum wasn't reactive at all in the displacement reactions, except with copper sulfate. Is there a reason? or did I make a mistake? aluminum is more reactive than e.g silver nitrate, why didn't it react with it?

- Aluminium has a protective coating of Aluminium Oxide, this prevents many chemicals reaching the surface. This is because aluminium has a very strong affinity for oxygen and bonds to it with extremely strong bonds. It can be removed by dipping it carefully into a solution of Mercury (II) Chloride.

- Q: Can aluminum sheets be painted or coated?

- Aluminum sheets have the ability to be painted or coated. Aluminum, being a versatile material, can easily be painted or coated in order to enhance its appearance or improve its performance. The key to successfully painting or coating aluminum lies in adequately preparing the surface and using appropriate primers or coatings specifically designed for aluminum. To achieve this, the aluminum sheet's surface must be thoroughly cleaned, devoid of any oils, dirt, or oxidation, and may require sanding or etching to promote adhesion. Once the surface is prepared, a wide array of paints or coatings can be applied, including liquid paints, powder coatings, and anodizing. These finishes offer various advantages such as heightened corrosion resistance, improved durability, enhanced aesthetics, and even specialized properties like heat resistance or anti-microbial properties. It is crucial to seek professional advice or adhere to the manufacturer's instructions to ensure the correct application and long-lasting effects of the paint or coating on aluminum sheets.

Send your message to us

Aircraft Grade Aluminum Sheets AA8006 D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords