Jeep Kl Cherokee Aluminum Coil Spacers - Aluminium Prepainted Coil with PVDF/PE 3XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

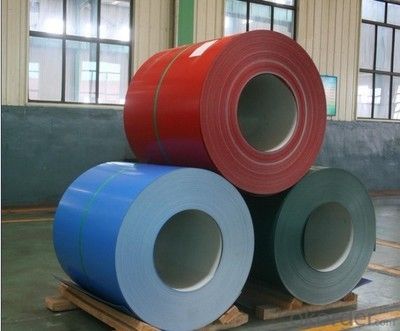

ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

High intensity.

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance.

Images of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX Specifications:

| Alloy | 1050 1060 1100 3003 3004 3005 3014 3105 3A21 5A02 5005 5052 5083 5251 6061 6063 etc |

| Temper | F O H12 H22 H14 H24 H16 H26 H18 H32 H34 H38 H111 H1112 H116 H321 T5 T6 etc |

| Thickness | 0.02mm - 1.2mm |

| Width | Standard width: 1200mm 1240mm ; Special width:1300mm 1520mm 1570mm 1595mm |

| Diameter | Standar dia: 1200mm ; Interior dia: 150mm 405mm 505mm |

| Weight | 1 T / coil -- 3 T / coil |

| Coating | PE PVDF ACRYLIC |

| Surface | Coated , Mill Finish ,Embossed |

| Color | Ral Color |

| Gloss | 10-90%(EN ISO-2813:1994) |

| Coating Thickness | PE: more than 18 micron PVDF : more than 25 micron |

Coating Hardness (pencilresistance) | More than 2 h |

| Coating Adhesion | 5J (EN ISO - 2409 : 1994 ) |

| Impact Resistance | No peeling or cracking (50kg / cm ,ASTMD - 2794 : 1993 ) |

| Flexibility(T-bend) | 2 T |

| MEK resistance | More than 100 |

| MOQ | 2 T |

| Payment Terms | TT or LC at sight |

| Applycation | Mainly in construction, decoration ,PCB materials, labels, house hold appliance ,lift, cover material ,LCD back panel, refrigeration, air conditioner ,automobile etc |

FAQ:

a: Where is your factory:

Henan Provence.

b:Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect

- Q: How are aluminum coils used in the production of sporting goods?

- Aluminum coils play a vital role in the production of sporting goods due to their lightweight, durable, and corrosion-resistant properties. These coils are primarily used in the manufacturing of sporting equipment such as baseball bats, tennis rackets, golf clubs, and bicycle frames. One of the key advantages of aluminum coils is their lightweight nature, which allows for enhanced maneuverability and improved performance. For instance, in the production of baseball bats, aluminum coils are used to create hollowed-out barrels that provide players with a better swing speed and increased power. Similarly, in tennis rackets and golf clubs, aluminum coils are utilized to construct the shaft, offering players greater control and maneuverability during gameplay. The durability of aluminum coils ensures that the sporting goods can withstand the rigors of intense physical activities. Whether it is the impact of a baseball hitting a bat or the force exerted on a bicycle frame during a rough ride, aluminum coils provide the necessary strength and resilience to withstand such pressures. This durability factor is crucial in ensuring the longevity of the sporting goods, reducing the need for frequent repairs or replacements. Furthermore, the corrosion-resistant properties of aluminum make it an ideal material for sporting equipment that may be exposed to various weather conditions or moisture. Aluminum coils are resistant to rust, ensuring that the sporting goods can maintain their performance and appearance over time. This quality is particularly beneficial in outdoor sports like golf or cycling, where exposure to rain, humidity, or perspiration is common. In summary, aluminum coils are extensively used in the production of sporting goods due to their lightweight, durable, and corrosion-resistant properties. These coils contribute to the overall performance, strength, and longevity of sporting equipment, enhancing the experience of athletes and enthusiasts alike.

- Q: What substances are used to make aluminum coils?

- <p>Aluminum coils are made from aluminum, a lightweight and malleable metal with the chemical symbol Al. They are typically produced from high-purity aluminum or aluminum alloys, which may include small amounts of other elements to enhance specific properties such as strength, durability, or resistance to corrosion. Pure aluminum is soft and lacks strength, so alloys are often used to improve these characteristics for various applications.</p>

- Q: What are the potential environmental impacts of aluminum coil production?

- There are several categories in which the potential environmental impacts of aluminum coil production can be classified. Firstly, the extraction of aluminum from bauxite ore requires significant amounts of energy and can contribute to the emission of greenhouse gases. Additionally, if not managed correctly, the use of toxic chemicals in the process can contaminate nearby water sources and soil. Moreover, the manufacturing of aluminum coils involves various stages, such as smelting, rolling, and annealing, each of which has its own environmental implications. For instance, smelting releases air pollutants like sulfur dioxide, nitrogen oxides, and particulate matter, resulting in air pollution and potential respiratory issues for nearby communities. Furthermore, the rolling process consumes a substantial amount of electricity, which may be derived from fossil fuel sources, leading to additional greenhouse gas emissions. Improper management of water usage in cooling and cleaning processes can also strain local water resources. Transportation is another factor to consider. Aluminum coils are often transported over long distances, contributing to carbon emissions from the burning of fossil fuels in trucks or ships. Lastly, the disposal of waste generated during the production process, such as scrap metal or chemicals, requires careful management to prevent pollution of landfills or nearby ecosystems. To mitigate these potential environmental impacts, companies can implement various strategies. These strategies include investing in more energy-efficient technologies, promoting recycling and the principles of a circular economy to reduce the need for primary aluminum extraction, adopting cleaner production techniques, and ensuring proper waste management and pollution control measures are in place.

- Q: What is the hardness range of aluminum coils?

- The hardness range of aluminum coils can vary depending on the specific alloy and temper. Aluminum coils can be produced in a wide range of hardness levels, from very soft to very hard. The hardness of aluminum is often measured using the Rockwell or Brinell hardness scales. Soft aluminum coils typically have a lower hardness range, ranging from 20 to 40 on the Rockwell scale. These soft coils are commonly used in applications where flexibility and formability are important, such as packaging, insulation, and electrical wiring. Hard aluminum coils, on the other hand, have a higher hardness range, typically ranging from 40 to 70 on the Rockwell scale. These coils are more rigid and have better mechanical properties, making them suitable for applications that require strength and durability, such as automotive parts, construction materials, and aerospace components. It is important to note that the specific hardness range of aluminum coils can also be influenced by factors such as the rolling process, heat treatment, and alloy composition. Therefore, it is always recommended to consult the manufacturer or supplier for the specific hardness range of the aluminum coils being considered for a particular application.

- Q: im looking for a bat but i dont know what to get wood or aluminum what is harder wood or aluminum ?? what would be better for hitting hard balls with ( or maybe people ) haha no im joking i need help !!!!

- Aluminum. When you hit the ball, it goes farther then a wooden bat. That is why MLB players can't use them, just in case of a line drive to the pitcher. They have enough problems dodging it, and this would get a lot more of them hit.

- Q: I don't know, I see a metal is a metal. I understand that a bike shop bike has better service and the bike has better components. Yet I just feel the frame of a $500 bike store bike and a $100 bike from Walmart using aluminum is the same. It's like people charging $100 for audio/video cables when a $1 no-name cable works the same for tv. Is this the same marketing ploy in the bike industry?I see a Mongoose bike for $500 to $1000 on their website, yet I see one with the same frame metal at Walmart/Kmart for only $100. Mongoose is a reputable name. What gives?What do you think? Is the metal quality in a $500 aluminum bike shop bike the same as a $100 aluminum department store bike?

- Customer service is a very important reason to buy a bike shop quality bike. A bike shop will have staff who actually know something about bicycles. They will make sure the bike is the right size for you fits you comfortably. They won't mind changing over parts (such as a saddle or a stem) to make the bike has comfortable as possible. They provide a bike with a decent warranty (on both the frame components) some free bike check-ups from a qualified mechanic. The mechanics don't mind adjusting the bike gears brakes for you, usually free of charge. And they have a wealth of knowledge, and don't mind answerering any questions you may have. These are all very good reasons to not buy a bike at a walmart store. EDIT - The dual suspension on cheap bikes are usually not very good quality. Don't expect to be able to do any real mountain biking with that kind of bike. It'll also have low quality gears brakes. Be prepared to learn how to do basic adjustments maintenance yourself, so it stays roadworthy. The metal quality might be similar, but the welding will not be as good as more expensive bikes. And what's the point in having a good frame if the components are low quality. It's the components which make the bike function as a bike.

- Q: Can aluminum coils be used in extreme weather conditions?

- Aluminum coils are capable of being utilized in the harshest weather conditions. With its exceptional durability and resistance to corrosion, aluminum proves to be a formidable material that can endure extreme heat, cold, humidity, as well as heavy rain or snow. Notably, it finds extensive employment in essential areas where weather resistance holds paramount importance, including air conditioning systems, refrigeration units, and outdoor equipment. These coils are expressly engineered to possess remarkable strength and dependability, ensuring their suitability for deployment in severe weather conditions, all the while maintaining optimal performance and lasting durability.

- Q: We have all heard the Us saying aluminum and their euro counterparts saying aluminium. I assumed this was just a small difference in culture or location. But, while reading my chemistry book (Chemistry the Central Science 12th) i came across a section saying: Cations formed from nonmetal atoms have names that end in -ium: NH4+ ammonIUM ion, H3O+ hydronIUM ion. So, i have came up with a hypothesis, could it be possible that when the periodic table was coming together, the aluminium was changed to aluminum to allow the rules to work? Thus making aluminum the correct spelling? Give me your thoughts.

- www.okorder ... aluminum (n.) 1812, coined by English chemist Sir Humphry Davy (1778-1829), from alumina, name given 18c. to aluminum oxide, from Latin alumen alum (see alum). Davy originally called it alumium (1808), then amended this to aluminum, which remains the U.S. word, but British editors in 1812 further amended it to aluminium, the modern preferred British form, to better harmonize with other metallic element names (sodium, potassium, etc.).

- Q: Can aluminum coils be used for solar panel installations?

- Yes, aluminum coils can be used for solar panel installations. Aluminum is a commonly used material in the construction of solar panels due to its lightweight, durability, and corrosion resistance properties. It is often used for framing and mounting systems to support and protect the solar panels.

- Q: This question asks about the differences between 3D printed aluminum coils and traditionally manufactured aluminum coils.

- <p>Yes, there are differences between 3D printed and regular aluminum coils. 3D printed aluminum coils are manufactured using additive manufacturing, which allows for complex geometries and customization. They can be produced with less material waste and can be designed for specific applications. Traditionally manufactured aluminum coils, on the other hand, are typically made through processes like rolling, which may not offer the same level of design flexibility. 3D printed coils may have different mechanical properties due to the layer-by-layer manufacturing process, potentially resulting in varying strength and durability. Additionally, 3D printed coils might have a higher cost due to the specialized equipment and materials required for additive manufacturing.</p>

Send your message to us

Jeep Kl Cherokee Aluminum Coil Spacers - Aluminium Prepainted Coil with PVDF/PE 3XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords