Painted Aluminum Coil Stock - Customized 5052 H36 Wide Aluminum Coil of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

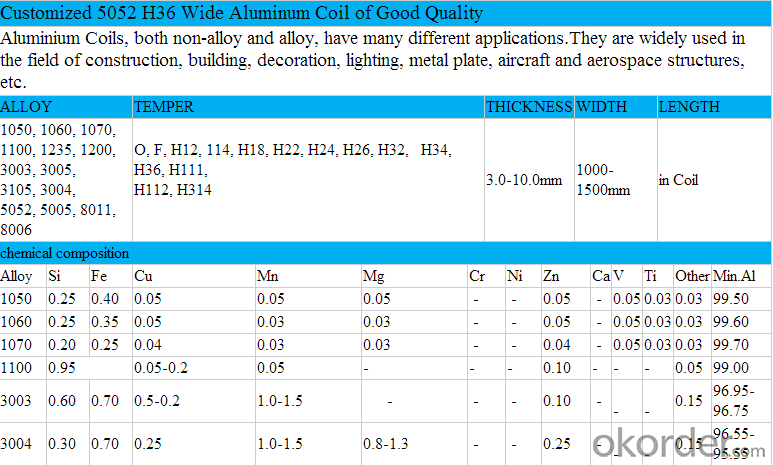

Customized 5052 H36 Wide Aluminum Coil of Good Quality

Aluminum coil is a kind of metal product. Rolled through by casting machine and processed by pull corner machine, aluminum coil is ready for the conduct of the shears. It is widely used in manufacturing aluminum thin sheet and aluminum foil. Aluminum coil is suitable for further machining with original standard quality. It is easy to controll and manufacture according to each customer's requirements.

5000 series aluminum alloys are more commonly used aluminum series, the main elements of magnesium, magnesium content between 3-5%. Also it can be called aluminum-magnesium alloy.

Aluminum Coil Specification:

l Packaging&Shipping

Packaging detail: Standard seaworthy exporting carton, wooden pallets, waterproof paper and plastic coverage or as customer's requirements.

Delivery detail: About 25 days from received original L/C or advance payment.

l Features

1. Name: Customized 5052 H36 Wide Aluminum Coil of Good Quality

2. Temper: O, F, HXX

3. Thickness: 3.0-10.0mm

4. Width: 1000-1500mm

5. Type: Coil/Roll

6. Surface Treatment: Mill finished

7. Application: Decoration, packaging, printing, covering

8. Standard size: Upon customer's demand

9. Quantity: 18tons(±10%)in one 20 feet container

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42800 employees and sales in 2005 of US Dollar 4.395 billion.

The Aluminum Product Department of CNBM manufactures and sells aluminum products including aluminum coils, aluminum foils, aluminum sheets, aluminum circles etc. With strong technical strength and strong ability to innovate, CNBM aluminum coils are being sold to many countries in around the world.

l CNBM World Wide

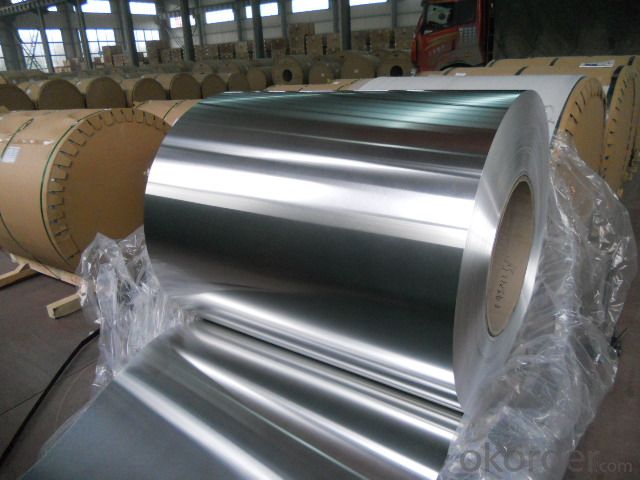

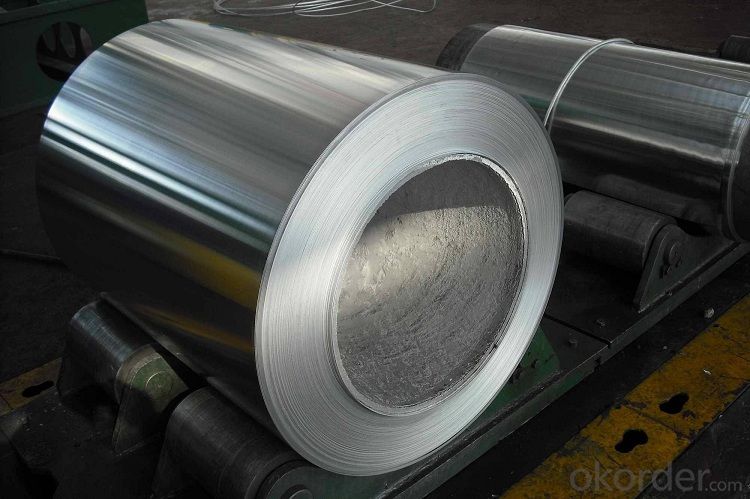

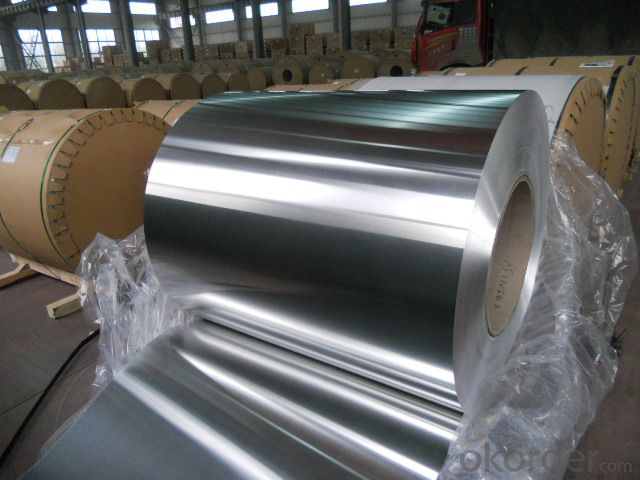

l Products images

l FAQ

Q: Do you provide free samples?

A: Yes, free aluminum coil samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

Fore more information about aluminum coil or other aluminum products, please contact service@okorder.com

- Q: Can aluminum coils be used in roofing applications?

- Yes, aluminum coils can be used in roofing applications. Aluminum is a popular choice for roofing due to its lightweight nature, corrosion resistance, and durability. Aluminum coils are commonly used in the construction of roofing systems, including standing seam roofs, metal shingles, and flat roofs. The coils are typically formed into panels or sheets that are installed on the roof, providing protection against weather elements and enhancing the aesthetic appeal of the building. Additionally, aluminum's reflective properties can help reduce energy consumption by reflecting sunlight and heat away from the building, making it an environmentally friendly choice for roofing applications.

- Q: Explain the distinctions among various welding equipment used specifically for joining aluminum coils.

- <p>Different types of welding equipment for aluminum coils include Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Resistance Welding (RW). GTAW, also known as TIG welding, uses a non-consumable tungsten electrode and produces high-quality welds with minimal distortion. GMAW, or MIG welding, uses a continuous wire feed as the electrode and is faster but may not be as precise. Resistance Welding involves using electrical current to heat the metals at the joint, which is quick and efficient but not suitable for all aluminum alloys. Each method has its advantages and is chosen based on factors like weld quality, speed, and the specific aluminum alloy being welded.</p>

- Q: Can aluminum coils be used for thermal insulation purposes?

- No, aluminum coils cannot be used for thermal insulation purposes. Aluminum is a highly conductive metal, meaning it easily transfers heat. Therefore, using aluminum coils as thermal insulation would actually promote heat transfer rather than preventing it. For effective thermal insulation, materials with low thermal conductivity, such as fiberglass, foam, or mineral wool, are commonly used. These materials create a barrier that limits heat transfer, keeping the desired temperature within a space.

- Q: Are aluminum coils suitable for medical equipment applications?

- Yes, aluminum coils can be suitable for medical equipment applications. Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity properties. These factors make it an ideal material for various medical equipment applications, such as cooling systems, heat exchangers, and MRI coils. Additionally, aluminum coils can be easily formed and fabricated into complex shapes, allowing for customization based on the specific requirements of the medical equipment. However, it is important to note that the suitability of aluminum coils for medical equipment applications may also depend on other factors such as the specific medical device, regulatory requirements, and industry standards.

- Q: What is the typical coefficient of friction for aluminum coils?

- The coefficient of friction for aluminum coils can differ based on numerous factors, including surface conditions, lubrication, and the specific aluminum alloy employed. Nevertheless, compared to other materials, aluminum coils generally exhibit a relatively low coefficient of friction. Typically, it ranges from 0.1 to 0.4.

- Q: Can aluminum coils be used in architectural applications?

- Aluminum coils, indeed, find application in architectural projects. The construction industry frequently employs aluminum due to its adaptability, endurance, and ease of manipulation. Architects often make use of aluminum coils for roofing, cladding, and facades, thanks to their malleability in creating diverse forms and proportions. Furthermore, these coils can be coated with various finishes to improve their visual appeal and safeguard against weathering and discoloration. Ultimately, given their blend of utility, attractiveness, and durability, aluminum coils have become a favored option for architectural purposes.

- Q: This question asks for the current prices of aluminum coils, which may vary based on factors such as weight, thickness, and market conditions.

- <p>The prices of aluminum coils can vary significantly depending on several factors including weight, thickness, grade, and market demand. Prices are also influenced by global economic conditions and the current state of the commodities market. As of my last update, aluminum coil prices could range from a few dollars to several hundred dollars per pound, but for the most accurate and up-to-date pricing, it's best to check with a supplier or a commodities exchange, as these prices fluctuate regularly.</p>

- Q: What are the different width tolerances for aluminum coils?

- The different width tolerances for aluminum coils can vary depending on the specific industry and application. However, common width tolerances for aluminum coils range from +/- 0.005 inches to +/- 0.030 inches.

- Q: What specific cleaning procedures should be followed for aluminum coils post-usage to ensure their longevity and functionality?

- <p>After using aluminum coils, it's important to clean them properly to maintain their performance and longevity. Typically, a mild detergent and warm water solution can be used to gently clean the coils. Avoid abrasive materials or harsh chemicals that could scratch the surface. Rinse thoroughly to remove all detergent residues. For stubborn residues, a soft cloth or sponge can be used. It's also crucial to dry the coils completely to prevent corrosion. Regular inspection and maintenance, including cleaning, will help extend the life of aluminum coils.</p>

- Q: What are the methods to prevent rust formation on aluminum coils during storage and transportation?

- <p>To prevent rust on aluminum coils during storage and transportation, ensure that the coils are clean and dry before storage. Store them in a cool, dry place away from moisture and corrosive substances. Use protective wrappings or coatings to shield the coils from the environment. Maintain proper ventilation to reduce humidity. Avoid stacking the coils directly on the ground; use pallets or racks to keep them off damp surfaces. Regularly inspect the coils for signs of moisture or damage and address any issues promptly.</p>

Send your message to us

Painted Aluminum Coil Stock - Customized 5052 H36 Wide Aluminum Coil of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords