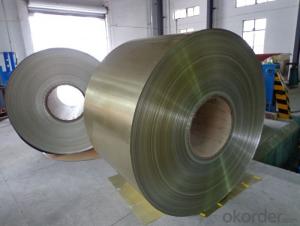

Jeep Kl Cherokee Aluminum Coil Spacers - Color Coated Aluminium Coils for Various Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification of Color Coated Aluminum Coil | |

Alloy | 1050 1060 1070 1100 1200 1235 / 3003 5052 5083 6061 6063 5005 etc. |

Alloy or not | Non-alloy / Alloy |

Temper | O, H112, T4, T5, T6, T651 etc. |

Specification | Thickness: 0.5mm - 500mm |

Width: 600mm - 2200mm | |

Length: 1000 - 6000mm or in coil size | |

Surface | coated |

Application | Heat preservation\ refrigerator\ Furniture\ decorate\ industry\ |

construction\ mould and so on | |

Features | 1.With good plasticity no matter in Cold and Hot condition; |

2. Can be pressed into various shapes of Construction Profile; | |

3. Easy to weld and cold process with good mouldability; | |

4. Can be processed into Sheet, Strip, Tube, Bar, Profile, Forged Piece, etc | |

5. Long life time. | |

MOQ | 3 Ton |

Package | wooden pallets or as customer request |

payment | 30% by T/T as deposit, and the rest 70% balance before loading. |

Delivery time | 15-30 days after receiving the deposit. |

Coating of Color Aluminum Coil

Coating thickness | PVDF >=25micron POLYESTER>=18micron |

Color standard | E < 2 or it is not obvious by eyeballing |

Pencil hardness | > 2HB |

Coating adhesive | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

Bend strength | >100 times |

Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive | surface deep in the 5% muriatic acid and 5% NaCL, |

interior deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

Application of Color Coated Aluminum Coil

Main Usage: Aluminium curtaim wall, Aluminium Composite Panel, Aluminium Honeycomb Plate, Ceiling,

Roof, Roller Shutter Door, Garages Door, Furniture, Electronic Industry, etc.

Our services

Main Services:

> Precision aluminum plate

> Casting products

> Forging products

Special Services:

> Alloy selection

> Aluminum machining techniques

> Hot working

> Surface treatment

Our Promise

---High quality stainless steel with reasonable price.

---Wide excellent experiences with after-sale service.

---Every process will be checked by responsible QC.

---Professional packing teams which keep every packing safely.

---Trial order can be done in one week.

---Samples can be provided as your requirements.

- Q: Can aluminum coils be used for food storage containers?

- Yes, aluminum coils can be used for food storage containers. Aluminum is a popular choice for food storage containers due to its many beneficial properties. It is lightweight, durable, and has excellent thermal conductivity, meaning it can evenly distribute heat for efficient cooking or cooling. Additionally, aluminum is non-toxic, odorless, and resistant to corrosion, making it a safe option for storing food. It also provides an effective barrier against light, moisture, and oxygen, which helps to preserve the freshness and quality of the stored food. Overall, aluminum coils can be a reliable and practical choice for food storage containers.

- Q: Can you create a tank, AFV, IFV etc. from aluminium or is this just a stupid idea that would kill everyone inside?

- Most military vehicles these days are made out of a super high grade strength linoleum. That way, if they're ever needed to be lifted out by a helicopter or some other flying vehicle, they're light enough. And it also is easier to repair damage and clean off blood stains as compared to other types of metal.

- Q: Are there any limitations on the width-to-thickness ratio of aluminum coils?

- Yes, there are limitations on the width-to-thickness ratio of aluminum coils. The specific limitations depend on various factors such as the intended application, manufacturing process, and the mechanical properties of the aluminum alloy being used. Generally, a higher width-to-thickness ratio can result in increased material instability, difficulty in handling, and potential quality issues. Therefore, it is necessary to carefully consider these factors and consult industry standards and guidelines to determine the appropriate width-to-thickness ratio for aluminum coils.

- Q: Is aluminium a safe metal to put in ones mouth without any side effects?

- I just saw a post on Facebook to whiten your teeth....just like professionals. Put salt,baking soda, and toothpaste mixed together. Spread on teeth. Wrap aluminum foil over teeth and let set. So I'm wondering if the aluminum foil at this point leeches into your mouth???

- Q: Is it advisable to purchase and utilize recycled aluminum coils without initial quality assessment?

- <p>No, it is not safe to buy and use recycled aluminum coils without first checking their quality. Recycled aluminum coils may have inconsistencies in thickness, strength, and purity, which can affect the performance and safety of the final product. It's crucial to inspect the coils for any defects, impurities, or deviations from the required specifications to ensure they meet the standards necessary for your application. Quality control is essential to prevent failures, maintain safety, and uphold the integrity of your manufacturing process.</p>

- Q: Can aluminum coils be used in food packaging?

- Indeed, food packaging can make use of aluminum coils. Aluminum, a secure and adaptable substance, has enjoyed extensive usage in the food packaging sector for numerous years. It provides numerous advantages, including its lightweight nature, resistance to corrosion, and exceptional thermal conductivity. These qualities render it perfect for food packaging scenarios that prioritize the maintenance of food product quality, freshness, and safety. Aluminum coils can be conveniently molded into various shapes and dimensions, permitting tailored packaging solutions. Furthermore, aluminum qualifies as a sustainable material due to its 100% recyclability, further augmenting its allure for food packaging purposes.

- Q: What is the weight of an aluminum coil?

- The weight of an aluminum coil can vary depending on its size, thickness, and length. On average, aluminum coils typically weigh between 1,500 and 6,000 pounds. However, it is essential to note that specific aluminum coils can weigh more or less depending on the specific requirements and specifications of the coil.

- Q: What are cold rolled aluminum coils and hot rolled aluminium coils, what are their respective features?

- The difference between hot rolling and cold rolling is that cold rolling is rolled at recrystallization temperature and hot rolling is above the recrystallization temperature.

- Q: This question asks for precautions that should be taken when handling aluminum coils to ensure safety.

- <p>When handling aluminum coil, it's crucial to follow safety measures to prevent accidents and injuries. Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and closed-toe shoes. Ensure that the work area is well-lit and free from clutter to avoid trips and falls. Use lifting equipment, such as cranes or forklifts, for heavy coils and never attempt to lift them manually. Keep the coils dry to prevent corrosion and ensure they are stored properly on wooden pallets or racks to prevent damage. Be aware of the risk of aluminum dust, which can be a fire hazard, and ensure proper ventilation is in place. Regularly inspect the coil for any sharp edges or damage that could cause injury. Always follow the manufacturer's guidelines and adhere to local safety regulations.</p>

- Q: What is the role of aluminum coils in the construction of railways?

- Aluminum coils are used in the construction of railways for various purposes, primarily for the manufacturing of overhead lines and electrical conductors. Due to their high conductivity, lightweight nature, and corrosion resistance, aluminum coils are ideal for transmitting electrical power and ensuring efficient and reliable railway operations. These coils are also utilized in the production of railway carriages and components, providing strength and durability while reducing overall weight, which ultimately improves fuel efficiency and lowers operating costs. Overall, aluminum coils play a crucial role in enhancing the performance, safety, and sustainability of railway systems.

Send your message to us

Jeep Kl Cherokee Aluminum Coil Spacers - Color Coated Aluminium Coils for Various Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords