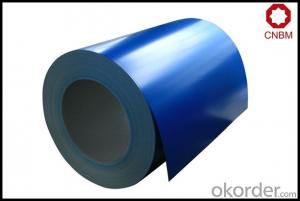

Collapsible Aluminum Coiler PE Paint Prepainted Aluminum Sheet Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE Aluminum Coating Coils for ACP

Features of PE Aluminum Sheet:

1. Adopting precision rolling coatingtechnology, our PVDF and PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PE coated aluminum coil weproduced, there are various colors for your choice.

3. Using infrared heating technology toprotect environment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wall panels, advertisement boards, counters,home appliances, decoration in and out of autos and boats.

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: How do aluminum coils contribute to recyclability in the construction industry?

- The inherent properties and characteristics of aluminum coils play a vital role in improving recyclability in the construction industry. To begin with, aluminum is a material that can be recycled repeatedly without losing its quality or physical properties, making aluminum coils an eco-friendly and sustainable option for construction projects. The recyclability of aluminum coils aids in reducing the environmental impact associated with the construction industry. By opting for aluminum coils, construction companies can contribute to the preservation of natural resources and the reduction of energy consumption. Recycling aluminum requires much less energy compared to producing it from raw materials, resulting in a significant decrease in greenhouse gas emissions and carbon footprint. Furthermore, the use of aluminum coils in construction simplifies the dismantling and deconstruction processes, making it easier to separate the aluminum components from other materials. This efficient separation allows for effective recycling of aluminum coils, ensuring that they can be transformed into new products or materials. Moreover, aluminum's durability and resistance to corrosion make it a suitable choice for construction applications. Its long lifespan reduces the need for frequent replacements, thereby minimizing waste generation and the consumption of raw materials. When the time comes to replace or renovate a building, the aluminum coils can be effortlessly collected, recycled, and reintroduced into the manufacturing cycle, completing the material's lifecycle. In conclusion, aluminum coils play a significant role in enhancing recyclability in the construction industry. Their high recyclability, low energy requirements for recycling, and ease of separation during deconstruction make them an environmentally friendly choice. By utilizing aluminum coils, the construction industry can promote sustainability, reduce waste generation, and conserve natural resources, ultimately leading to a greener and more circular construction sector.

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum's low coefficient of friction and excellent thermal conductivity make it a suitable material for various applications where low friction is desired, such as in sliding mechanisms, bearings, and electrical connectors.

- Q: What are the potential health hazards linked to the use of aluminum coils?

- <p>There are concerns about the use of aluminum coils due to the possibility of aluminum leaching into food during cooking. Aluminum has been linked to various health issues, including cognitive decline and Alzheimer's disease, although the evidence is not conclusive. Additionally, aluminum exposure may lead to bone and neurological disorders. However, the health risks associated with aluminum coils are still a subject of debate among researchers. It's recommended to minimize exposure to aluminum by using alternative cooking methods or materials, such as stainless steel or cast iron.</p>

- Q: What are the potential applications of mill-finished aluminum coils?

- Mill-finished aluminum coils have a wide range of potential applications due to their excellent corrosion resistance, lightweight nature, and versatility. Some common applications include roofing, insulation, cladding, automotive parts, electronic casings, and packaging materials. Additionally, mill-finished aluminum coils can be further processed or coated to suit specific needs in industries such as construction, transportation, aerospace, and consumer goods.

- Q: What are the common surface finishes for aluminum coils in the electrical industry?

- In the electrical industry, aluminum coils are commonly used for various applications such as transformers, motors, and electrical enclosures. These coils are often subjected to different surface finishing processes to enhance their performance and longevity. One of the most common surface finishes for aluminum coils in the electrical industry is anodizing. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. This layer not only provides excellent corrosion resistance but also improves the coil's durability and electrical insulation properties. Another popular surface finish is chemical conversion coating, also known as chromate conversion coating. This process involves treating the aluminum surface with a chemical solution to create a thin layer of protective coating. The coating not only provides corrosion resistance but also improves the adhesion of subsequent coatings or paints applied to the coil. Powder coating is another common surface finish used in the electrical industry for aluminum coils. It involves applying a dry powder onto the coil's surface and then curing it under heat to create a durable and attractive finish. Powder coating provides excellent resistance to chipping, scratching, and fading, making it ideal for applications where aesthetics and durability are important. In addition to these surface finishes, aluminum coils in the electrical industry may also undergo other treatments such as lacquering or painting. Lacquering involves applying a clear protective coating to the coil's surface, providing a glossy and protective finish. Painting, on the other hand, involves applying a colored coating to the surface for aesthetic purposes while also providing protection against corrosion. Overall, the choice of surface finish for aluminum coils in the electrical industry depends on the specific requirements of the application. Factors such as corrosion resistance, electrical insulation, durability, and aesthetics play a significant role in determining the most suitable surface finish for a given application.

- Q: What's the difference between an aluminum alloy strip and an aluminum coil?

- The specifications are different. Generally speaking, the aluminum strips are of small size, and the aluminum rolls are of large size

- Q: I'm asking about the aluminum tabs on soda cans. I've heard mixed things.

- Depends what you mean by site. A full service junkyard will pay by the pound for most kinds of metal, including washers dryers and stoves but you would need a lot of them to make it worthwhile at 60 cents a pound or so

- Q: I go on a trip once a year with a group of lets say 10 people, we go for 7 nights and consume on average approx 120 cans of beer each (throughout the week). We have a fire burning the whole time in a hole that we dig approx 1ft deep, then we dispose of each can in the fire and let them melt down never thinking about them again. That's approx 1,200 cans that melt in the one fire hole.Will the aluminum have an affect on the soil? does anyone know what sort of damage this can cause? and for what distance / area around the fire might be affected?The theory amongst the group is that cans do not hurt anything so that's why they take cans instead of glass.Thanks

- Aluminum is very reactive in air and will form a layer of aluminum oxide around the outside of any piece. This oxide layer is very stable which is why aluminum doesn't corrode. Since your block of aluminum will be totally oxidized being in a fire, it's inert and just going to sit in the hole for the foreseeable future. The burning paint might not be healthy to breath but that's about the only hazard. Most common soil is a mixture of aluminum, carbon and silica compounds anyways so you aren't even adding anything particularly exotic. Alternatively, you could bring along a couple fifths of whiskey. It's lighter and has less packaging so it's the environmentally friendly way to get drunk.

- Q: How are aluminum coils protected against moisture during storage?

- Aluminum coils are typically protected against moisture during storage through the use of various methods and materials. One common method is the application of a protective coating, such as a thin layer of oil or a corrosion-resistant film, which forms a barrier between the coil and any moisture present in the environment. This coating helps to prevent direct contact between the aluminum surface and water, minimizing the risk of corrosion or other moisture-related damage. In addition to protective coatings, aluminum coils may also be stored in a controlled environment with low humidity levels. This can be achieved by storing the coils in a dry warehouse or using dehumidifiers to remove excess moisture from the storage area. By controlling the humidity, the risk of moisture condensation on the coils is reduced, further protecting them from potential damage. Furthermore, proper packaging is crucial in protecting aluminum coils against moisture during storage. Coils are often wrapped in moisture-resistant materials, such as plastic or moisture-proof paper, to create a barrier that prevents moisture from reaching the coils. Additionally, the packaging is often sealed to provide an airtight environment, further minimizing the chances of moisture ingress. Regular inspection and maintenance are also important to ensure the continued protection of aluminum coils during storage. This includes checking the integrity of the protective coatings, monitoring the storage environment for any changes in humidity levels, and promptly addressing any signs of moisture damage. Overall, the use of protective coatings, controlled storage environments, proper packaging, and regular maintenance are key factors in protecting aluminum coils against moisture during storage. By implementing these measures, the risk of moisture-related damage is significantly reduced, ensuring the quality and integrity of the coils until they are ready for use.

- Q: Normal aluminum like you find in the ground, not the man made stuff

- ALL aluminum is man made. What exists in the ground is aluminum-oxide which is a white/grey granular material. The oxide is converted into the base metal by use of an electric arc furnace. (the power bill is huge) Aluminum as the metal you are familiar with in recyclable soda cans does NOT exist in nature. NO, aluminum is a metal, and like all other metals, only glows if heated to a high enough temperature to do so... You can recycle 100 cans for the cost of what it takes to make the aluminum for ONE NEW can.

Send your message to us

Collapsible Aluminum Coiler PE Paint Prepainted Aluminum Sheet Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords