Aluminum Coil 0.05 X 102 - Wooden Pattern Roll Coated Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Pattern Roll Coated Aluminum Coil

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

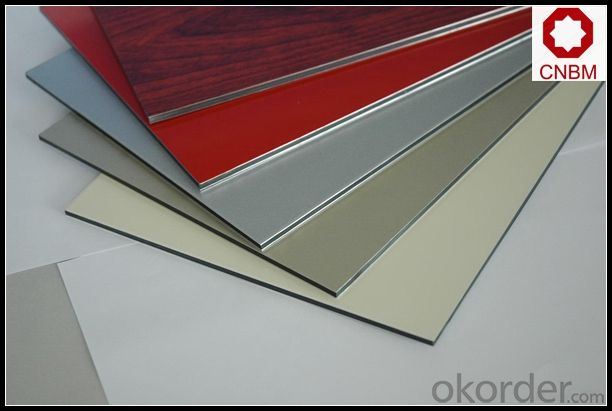

2. Application of Wooden Pattern Roll Coated Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Pattern Roll Coated Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

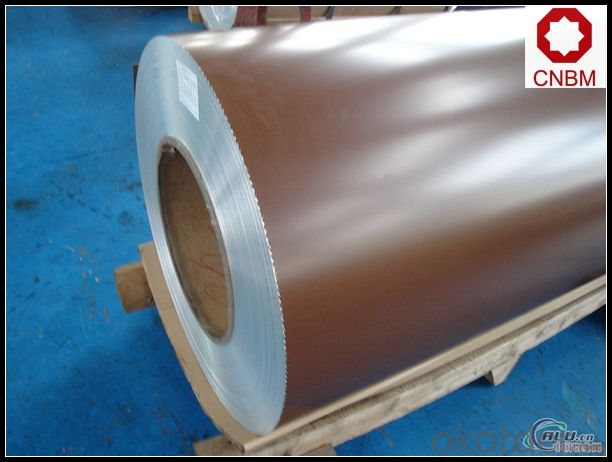

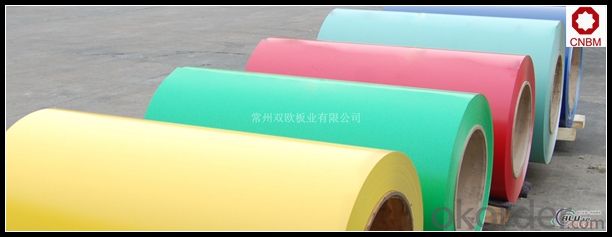

5. Image of Wooden Pattern Roll Coated Aluminum Coil

6. Package and shipping of Wooden Pattern Roll Coated Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the fire resistance properties of aluminum coils?

- Aluminum coils have excellent fire resistance properties due to the unique characteristics of the metal. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which allows it to withstand high temperatures without deforming or melting. In addition, aluminum forms a thin layer of oxide on its surface when exposed to air, which acts as a protective barrier against fire and prevents further oxidation. This oxide layer has a high melting point and is non-combustible, making it an effective fire retardant. Furthermore, aluminum is a poor conductor of heat, meaning it does not readily transfer heat during a fire, which helps to slow down the spread of flames. Therefore, aluminum coils are widely used in various applications where fire resistance is a crucial requirement, such as in building construction, transportation, and electrical wiring.

- Q: We are working on a new aluminum fixture. It is basically an aluminum spine with many 6061-T6 pins sticking out. Currently we drill the holes inside the spine and hammer the 5/32 6061-T6 pins inside. Is there anyway to cast aluminum with many 6061-T6 pins embedded (they will stick out after the casting)?

- How long are the pins? have you considered casting the pins along with the rest of the part? or is that what you are asking, it sounds, like you are talking about loading pins into the mold and having the cast spine bond with them. What casting process are you using, or are you even using a casting now, or is the spine currently rolled or extruded shapes? As mentioned on RCM, the pins will no longer be T6 after casting, if you need the T6 temper the part will have to be heat treated.

- Q: I planned on making heart shaped pancakes for Valentine's day - is it ok to use aluminum foil as the mold for it? If so, how should I go about it?

- No, a stove top produces hot points. Better to just shape the pancakes with the spatula.

- Q: What is the typical warranty period for aluminum coils?

- The typical warranty period for aluminum coils varies depending on the manufacturer and the specific application. However, it is common to find warranties ranging from 5 to 10 years for residential applications, while commercial warranties can extend up to 20 years or more. It is recommended to check with the manufacturer or supplier for the exact warranty details for specific aluminum coil products.

- Q: Is it possible to utilize an angle grinder for cutting hot rolled aluminum coils?

- <p>Yes, you can use an angle grinder to cut hot rolled aluminum coils, but you must take precautions. Use a grinding disc specifically designed for metal cutting, preferably one with a diamond or carbide grit for better performance on aluminum. Ensure the grinder is equipped with a safety guard and wear appropriate safety gear, including goggles and gloves. Be aware that aluminum can be reactive when heated, so cutting may produce sparks and fumes; ensure proper ventilation. Always follow the manufacturer's guidelines for your specific angle grinder and safety regulations.</p>

- Q: Can aluminum coils be utilized as an insulating material?

- <p>Aluminum coils are not typically used for insulation. They are good conductors of heat and electricity, which makes them unsuitable for insulation purposes. Insulation materials should be poor conductors to prevent the flow of heat or electricity. Aluminum coils are more commonly used in applications where conductivity is desired, such as in electrical wiring or heat exchangers. For insulation, materials like fiberglass, mineral wool, or plastic foams are used because they resist heat flow effectively.</p>

- Q: What are the methods to prevent rust formation on steel coils during storage and transportation?

- <p>To prevent rust on steel coils during storage and transportation, follow these steps: 1. Keep the coils dry and avoid exposure to moisture. 2. Use rust inhibitors or anti-corrosion coatings on the coils. 3. Store the coils in a clean, dry, and well-ventilated area. 4. Use protective wrapping materials like plastic film or corrosion-resistant paper. 5. Ensure proper stacking and avoid direct contact between coils. 6. Use rust-resistant materials for transportation containers. 7. Regularly inspect the coils for signs of rust and address any issues promptly. By implementing these measures, you can significantly reduce the risk of rust formation on steel coils.</p>

- Q: What are the potential safety hazards when using a soldering iron on copper or aluminum coils?

- <p>Using a soldering iron to solder copper or aluminum coils can pose safety risks. Copper and aluminum can react when joined, potentially leading to a galvanic corrosion. Additionally, the high heat from the soldering iron can cause the metal to expand or deform, especially if not handled properly. Always ensure proper ventilation to avoid inhaling fumes from the soldering process. Wear heat-resistant gloves and safety glasses to protect against burns and flying debris. Ensure the work area is clear of flammable materials to prevent fire hazards.</p>

- Q: Can aluminum coils be used in the production of fire-resistant structures?

- Indeed, the utilization of aluminum coils is possible for the fabrication of fire-resistant structures. Being inherently fire-resistant and possessing a remarkably high melting point, aluminum emerges as an excellent substance for structures that necessitate endurance against elevated temperatures. In the realm of construction, aluminum coils are frequently employed to fulfill fire-resistant requirements, including roofs, walls, and insulation. Moreover, the lightweight and durability of aluminum further facilitate the installation and maintenance of fire-resistant structures.

- Q: Is it possible to use a saw to cut aluminum coils?

- <p>Yes, aluminum coils can be cut with a saw, but it's important to use the right type of saw. A hacksaw or a fine-toothed metal cutting saw is suitable for cutting aluminum. Lubrication is also crucial to reduce friction and prevent the saw blade from overheating. When cutting aluminum, it's advisable to use a cutting fluid or a light machine oil to keep the blade cool and ensure a clean, smooth cut. Always follow safety precautions and wear appropriate protective gear when cutting metal.</p>

Send your message to us

Aluminum Coil 0.05 X 102 - Wooden Pattern Roll Coated Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords