High Quality Insulating Fire Brick GJM23-26 Insulation Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Insulation Brick:

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay..

2.Main features of Insulation Brick:

◆Light weight and low thermal conductivity ◆Low heat storage

◆Low iron and impurities ◆High thermal shock resistance

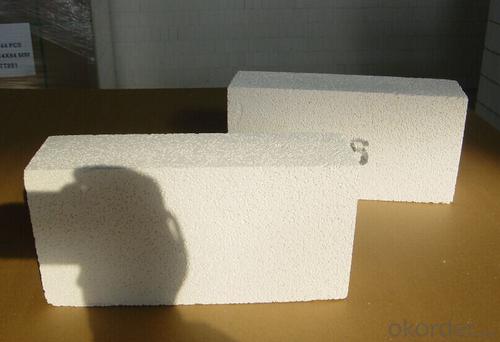

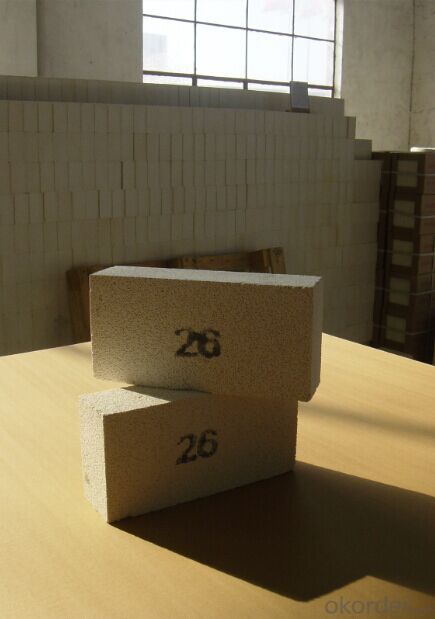

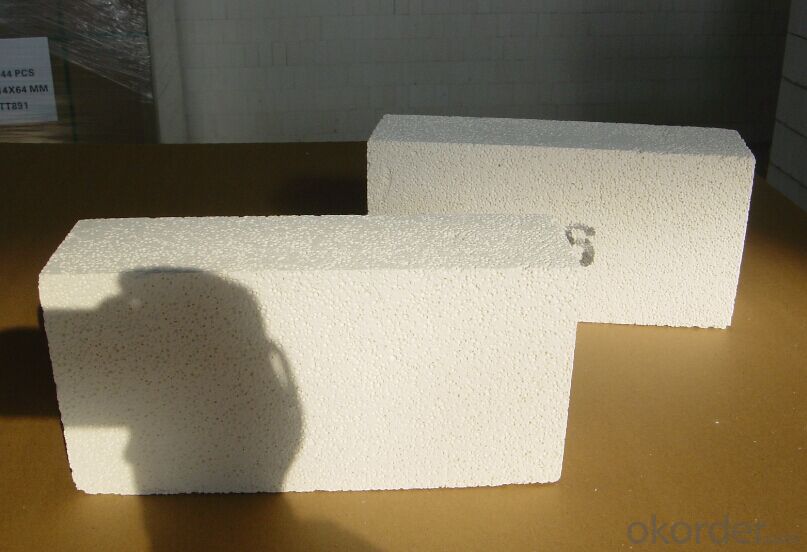

3. Insulation Brick Images:

4. Insulation Brick Technical Parameters

Our Insulation Brick contains 20, 23, 25,26, 28, 30, 32. Classification temperature is from 1100℃ to 1760℃. Density is from 0.52g/cm3 to 1.25g/cm3. As we all know, the company type is 23 and 26.

1) For the 23, its density is 0.52g/cm3, but some customer may require 0.8g/cm3, we can also meet your special require. Content of Al2O3 is about 45%.

2) For the 26, its density is 0.8g/cm3, but if you have other special requirement on that, pls also tell us. Content of Al2O3 is about 55%.

Application: CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our Insulation Brick?

A world class manufacturer & supplier of InsulationBrick is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can insulating fire bricks be used in refractory castings?

- Yes, insulating fire bricks can be used in refractory castings. Insulating fire bricks are lightweight and have high insulating properties, making them suitable for applications that require thermal insulation. This includes refractory castings, which are used to create linings in furnaces, kilns, and other high-temperature equipment. The insulating fire bricks can be used as a layer or as a part of the refractory casting mix to provide thermal insulation and reduce heat loss. Additionally, their low thermal conductivity helps in minimizing energy consumption and maintaining high temperatures within the casting.

- Q: Can insulating fire bricks be used in the construction of tundishes?

- Insulating fire bricks are indeed applicable for tundish construction. They possess exceptional thermal insulation qualities and are lightweight, which makes them perfect for situations that demand heat retention. Tundishes, utilized in the steel industry to regulate molten metal flow, necessitate materials capable of enduring high temperatures while minimizing heat loss. Insulating fire bricks excel in this area, successfully enduring extreme temperatures within tundishes, thereby safeguarding the desired molten metal temperature and preventing heat loss. Moreover, their lightweight nature facilitates uncomplicated handling and installation during tundish construction. In conclusion, insulating fire bricks prove to be a suitable choice for tundish construction due to their thermal insulation qualities and ability to withstand high temperatures.

- Q: How do insulating fire bricks perform in terms of sound insulation?

- Insulating fire bricks are primarily designed for excellent thermal insulation, but their performance in terms of sound insulation can vary. While they can provide some sound reduction due to their dense and non-porous nature, they are not specifically engineered for soundproofing. The level of sound insulation offered by insulating fire bricks depends on factors such as brick thickness, density, and sound frequency. Generally, insulating fire bricks can somewhat reduce high-frequency noises, but they may not be as effective in blocking low-frequency sounds. For superior sound insulation, specialized acoustic materials or construction techniques may be more appropriate.

- Q: Can insulating fire bricks be used in the construction of heat exchangers?

- Insulating fire bricks have the capability to be utilized in the construction of heat exchangers. These bricks are specifically designed to possess exceptional thermal insulation properties, thereby rendering them ideal for situations where the maintenance or control of high temperatures is necessary. Heat exchangers, which are devices responsible for the transfer of heat between two or more fluids, require insulation in order to prevent any loss or gain of heat during the process. The incorporation of insulating fire bricks in the construction of heat exchangers aids in the reduction of heat transfer to the surrounding environment, ultimately resulting in enhanced energy efficiency and decreased operational expenses. These bricks are capable of withstanding high temperatures, typically reaching up to 3000°F (1650°C), thus making them suitable for various heat exchanger applications, such as furnaces, boilers, and industrial processes. Moreover, insulating fire bricks possess the additional benefits of being lightweight and having low thermal conductivity. This means that they provide effective insulation while also being less bulky and more cost-effective compared to traditional refractory bricks. Consequently, they are easier to handle and install within heat exchanger systems. In conclusion, the utilization of insulating fire bricks in the construction of heat exchangers offers numerous advantages, including improved thermal insulation, enhanced energy efficiency, and reduced expenses.

- Q: Are insulating fire bricks resistant to insect infestations?

- No, insulating fire bricks are not specifically designed to be resistant to insect infestations.

- Q: How do insulating fire bricks help reduce heat loss through conduction?

- Insulating fire bricks help reduce heat loss through conduction by having low thermal conductivity. This means that they are poor conductors of heat, preventing the transfer of thermal energy from one side to the other. The bricks are made of materials with high porosity, which traps air within their structure. This trapped air acts as an insulator, minimizing the conduction of heat between the two sides of the brick. As a result, insulating fire bricks act as a barrier, reducing the amount of heat that is transferred through conduction and helping to maintain a more stable temperature.

- Q: Can insulating fire bricks be used in the construction of thermal oxidizers?

- Yes, insulating fire bricks can be used in the construction of thermal oxidizers. Insulating fire bricks have excellent thermal insulation properties, which make them ideal for applications where high temperatures need to be contained within a specific area. Thermal oxidizers are used to combust volatile organic compounds (VOCs) at high temperatures, and the use of insulating fire bricks can help maintain the required temperature within the combustion chamber while minimizing heat loss to the surroundings. Additionally, insulating fire bricks are lightweight, durable, and have good resistance to thermal shock, which further contributes to their suitability for use in thermal oxidizers.

- Q: Can insulating fire bricks be used for insulation in refractory lining repair?

- Yes, insulating fire bricks can be used for insulation in refractory lining repair. Insulating fire bricks are specifically designed to provide insulation in high-temperature environments, making them suitable for repairing refractory linings that require thermal insulation.

- Q: What is the maximum temperature range of high temperature resistant insulation materials?

- A class of inorganic non-metallic materials with a refractoriness of not less than 1580 degrees. Refractoriness is defined as the temperature of a sample of a refractory cone sample that resists high temperature without loading and does not soften and melt down. But only in terms of fire resistance can not be fully described refractories, 1580 degrees of temperature is not absolute.

- Q: Can insulating fire bricks be used in high-temperature ducts?

- Insulating fire bricks can indeed be used in high-temperature ducts. These bricks are specially designed to withstand extreme temperatures, making them an ideal choice for applications where heat retention and insulation are crucial. With their low thermal conductivity and high resistance to thermal shock, insulating fire bricks can effectively trap heat within the ducts, preventing any loss of energy and ensuring efficient heat transfer. Additionally, their lightweight nature makes them easy to install and handle, while their durability allows them to withstand the harsh conditions of high-temperature environments. Overall, insulating fire bricks are a reliable and effective solution for insulating high-temperature ducts.

Send your message to us

High Quality Insulating Fire Brick GJM23-26 Insulation Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords