Insulating Fire Brick - Refractory High Alumina Thermal Insulating Fire Brick 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Refractory High Alumina Thermal Insulating Fire Brick 2015

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | international index | Al2O3 Content (%): | ≥48 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | LG-1.0 | Brand Name: | |

| Sample: | Free | Fe2O3 %: | ≤2 | Bulk Density, g/cm3: | ≤1.0 g/cm3 |

| Cold crushing strength(Mpa): | ≥3.9 | temp linear change on reheating: | 1400 | Thermal conductivity /W.(m.k)-1: | ≤0.5 |

| size: | 230mm*114mm*65/75mm | HS code: | 6902200 |

Packaging & Delivery

| Packaging Details: | Packed on wooden pallets, with water-proof cover, all measurements of each case is 1050mm*1050mm*1050mm. We will pack the goods according to your requirement. |

| Delivery Detail: | 10~30 days after receiving your payment |

refractory lightweight high alumina thermal insulating fire brick

Product Description

Refractory lightweight high alumina thermal insulating fire brick is made out of a naturally-occurring material known as bauxite. This material includes aluminum hydroxide, which is what gives the bricks such great warmth resistance. The bricks also include kaolinitic clays, which are roasted to create an unique combination including mullite and also synthetic alumina. This is where the name “high alumina” stems from.

Features

1.High-temperature endurable .

2.Good thermal shock resistance .

3.High cold crushing strength.

4.Good resistance to abrasion and corrosion.

5.Good thermal spalling resistance.

6.High mechanical strength.

7.Good volume stability at high temperature.

Application

1.General use in heat containment unit form temperature 1500-2000°C.

2.Resistant to highest temperature for steelmaking operations such as ladle applications, sidewall, roofs, burner blocks, anchor brick for reheating furnaces and many other areas.

3.transition and cooling zones of rotary cement kilns, lime kilns , etc.

4.lower sidewall and bottom of aluminum refining,melting furnaces ,etc.

Technical Data

Description of parameters |

Index of high alumina lightweight fire brick | ||||||

LG- 1.0 | LG-0.9 | LG-0.8 | LG-0.7 | LG-0.6 | LG-0.5 | LG-0.4 | |

AL2O3 % | ≥48 | ||||||

Fe2O3 % | ≤2.0 | ||||||

Bulk Density, g/cm3 | ≤1.0 | ≤0.9 | ≤0.8 | ≤0.7 | ≤0.6 | ≤0.5 | ≤0.4 |

Cold Crushing Strength MPa | ≥3.9 | ≥3.4 | ≥2.9 | ≥2.5 | ≥2.0 | ≥1.5 | ≥0.8 |

Test temp linear change within 2%on reheating | 1400 | 1400 | 1400 | 1350 | 1350 | 1250 | 1250 |

Thermal conductivity /W.(m.k)-1 | ≤0.5 | ≤0.45 | ≤0.35 | ≤0.35 | ≤0.30 | ≤0.25 | ≤0.20 |

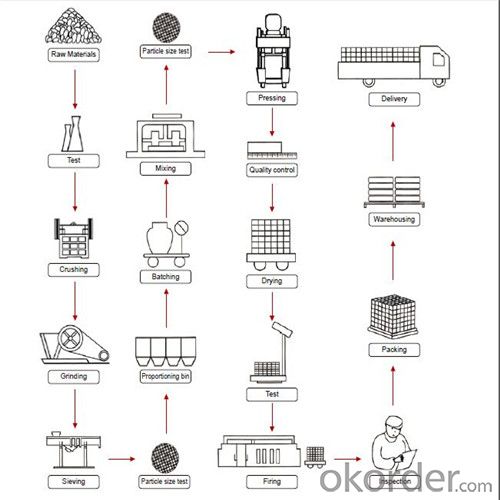

Packaging & Shipping

1. Strong packing will protect the goods from any possible damage during transit.

2. Solid packing and overall stuffing can prevent the cases from vibration and jarring.

3. We must take necessary precaution that the packing can protect the goods from pilferage or rain.

4. l can confirm that we take every possible precaution to ensure that our products reach our customers all over the world in prime conditon.

Our Services

1.We will reply to you immediately, if you have any question.

2.We can provide free samples for you.

3.we have all kinds of fire bricks ,for example,high alumina brick ,fireclay brick, corundum brick, refractory ball, allotypic brick, lightweight brick and so on. We can offer you products of a wide range of specifications.

Why choose us

1.We are professional manufacturer of refractory brick and had been in this line for more than 20 years .

2.Our products quality will be guaranteed . We have our own technical team to test the products before delivery.

3.Competitive prices based on same quality. Guarantee samples quality same as mass production quality.

4.Adhering to the business philosophy "mutual trust, mutual benefit, mutual profit, faith oriented".

5.We can according to your requirements to produce your order and OEM/ODM service is available.

6. Products are inspected through SGS and BV etc and accord with the international standard.

7.Your inquiry related to our products or prices will be replied in a timely manner.

8. We provide the best after sales service.

- Q: Can insulating fire bricks be cut or shaped to fit specific dimensions?

- Insulating fire bricks possess the capability to be tailored or molded according to particular dimensions. Composed of lightweight refractory materials, these bricks are purposely designed to facilitate easy cutting or shaping to fulfill specific necessities. A saw, knife, or alternative cutting tools are suitable for cutting them, while grinding or sanding can be employed to shape them. Such adaptability allows for meticulous customization of the bricks, rendering them a versatile choice for a myriad of applications, including lining furnaces, kilns, and other environments with elevated temperatures.

- Q: Can insulating fire bricks be used for insulation in power boiler walls?

- Yes, insulating fire bricks can be used for insulation in power boiler walls. Insulating fire bricks are specifically designed to have low thermal conductivity, allowing them to effectively insulate high temperature environments such as power boilers. They are made from lightweight materials such as clay and other refractory materials, which provide excellent insulation properties while withstanding the extreme heat conditions found in power boilers. The use of insulating fire bricks in power boiler walls helps to reduce heat loss, improve energy efficiency, and maintain high operating temperatures within the boiler.

- Q: Can insulating fire bricks be used in ladles?

- Certainly! Ladles can indeed utilize insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures while offering thermal insulation. They find frequent application in situations where the maintenance or regulation of high temperatures is necessary, like furnaces, kilns, and ladles. Ladles are employed for the purpose of pouring and transferring molten metal or other substances. By incorporating insulating fire bricks into ladles, heat loss is reduced and energy efficiency is enhanced. Moreover, these bricks serve as a safeguard against chemical reactions and erosion stemming from the molten materials, thus qualifying them as suitable for ladle usage.

- Q: Can insulating fire bricks be used in rocket stoves?

- Yes, insulating fire bricks can be used in rocket stoves. In fact, they are often preferred for their high insulation properties. Insulating fire bricks are made from lightweight refractory materials, such as silica, which have low thermal conductivity. This means that they are able to withstand high temperatures while minimizing heat loss, making them an ideal choice for rocket stoves. Rocket stoves are designed to efficiently burn biomass fuel, such as wood or charcoal, by creating a combustion chamber with a vertical chimney. The insulating fire bricks can be used to construct the combustion chamber and line the chimney, ensuring that the heat generated by the fire is effectively contained and directed towards the cooking surface. By using insulating fire bricks, rocket stoves can achieve higher temperatures and maintain them for longer periods of time. This results in more efficient and effective cooking, as well as reduced fuel consumption. Additionally, the insulating properties of these bricks also help to protect the surrounding environment from excessive heat, reducing the risk of accidental burns or fires. Overall, insulating fire bricks are a suitable choice for rocket stoves due to their ability to withstand high temperatures, minimize heat loss, and improve the efficiency of the cooking process.

- Q: Can insulating fire bricks be used in biomass boilers?

- Yes, insulating fire bricks can be used in biomass boilers. Insulating fire bricks are designed to have low thermal conductivity, which helps to retain heat within the boiler and increase its overall efficiency. In biomass boilers, these bricks can be used to line the combustion chamber, helping to keep the heat inside and prevent it from escaping. Additionally, insulating fire bricks can withstand high temperatures, making them suitable for use in biomass boilers where combustion temperatures can reach several hundred degrees Celsius. Overall, the use of insulating fire bricks in biomass boilers can enhance their thermal efficiency and contribute to a more efficient and sustainable energy production process.

- Q: Can insulating fire bricks be cut or shaped to fit specific applications?

- Yes, insulating fire bricks can be cut or shaped to fit specific applications. Insulating fire bricks are made from lightweight refractory materials, typically ceramic fibers or lightweight aggregates, which allows them to be easily cut or shaped without compromising their structural integrity. They can be cut with a saw, knife, or other cutting tools to fit specific dimensions or shapes required for various applications, such as lining kilns, furnaces, or fireplaces. Additionally, insulating fire bricks can be shaped by using molds or by hand molding during the manufacturing process. This flexibility in cutting and shaping makes insulating fire bricks highly versatile and suitable for a wide range of industrial and residential applications.

- Q: What is the typical bulk density of an insulating fire brick?

- The typical bulk density of an insulating fire brick is around 0.6 to 1.2 grams per cubic centimeter (g/cm³).

- Q: Can insulating fire bricks be cut or shaped using common tools?

- Indeed, common tools can be utilized to cut or mold insulating fire bricks. These bricks are typically composed of lightweight refractory substances like clay and minerals, making them more amenable to cutting and shaping than conventional fire bricks. To achieve the desired dimensions and design, one can employ basic tools such as a handsaw, angle grinder, or even a chisel and hammer. However, it is crucial to prioritize safety when handling insulating fire bricks by donning protective gear like gloves, goggles, and a dust mask. This precautionary measure is necessary to avert any potential health risks.

- Q: Are insulating fire bricks resistant to vibrations?

- Insulating fire bricks are generally not designed to be resistant to vibrations. While they are known for their excellent thermal insulation properties, their resistance to vibrations is typically limited. Insulating fire bricks are made from lightweight materials such as ceramic fibers, vermiculite, or perlite, which are not particularly known for their ability to dampen or absorb vibrations. Therefore, if a specific application requires resistance to vibrations, it may be advisable to consider alternative materials or designs that are better suited for such conditions.

- Q: Can insulating fire bricks be used for high-temperature insulation?

- Yes, insulating fire bricks can be used for high-temperature insulation. These bricks are specially designed to withstand extreme temperatures, making them suitable for insulation in applications such as kilns, furnaces, and fireplaces. They have excellent thermal conductivity and can effectively reduce heat loss, making them an ideal choice for high-temperature insulation needs.

Send your message to us

Insulating Fire Brick - Refractory High Alumina Thermal Insulating Fire Brick 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords