Insulating Fire Brick - Refractory Mullite Insulating Fire Brick for Heating Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of High Purity Corundum Brick:

High purity corundum brick SiO2<0.2%, Al2O3>99%, used in petrochemical industry furnace, gasification furnace and large fertilizer equipment, and more than 1600° C super high temperature furnace, liner of furnace. Long life and reliable in quality. We can make different kinds of shape products according the customer's drawing.

2. Main features of High Purity Corundum Brick

1. High compression strength.

2. Top high-temperature capability.

3. Excellent thermal stability.

4. Low thermal conductivity.

5. Powerful penetrating-proof capability.

6. Good erosion-resistance.

7. Long service life.

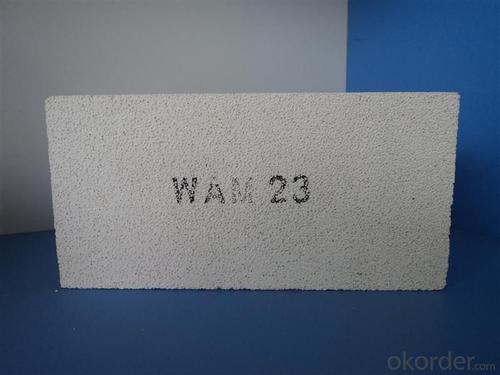

3. High Purity Corundum Brick Images:

4. Applications of High Purity Corundum Brick:

Mullite lightweight brick plant can be in direct contact with the flame,this insulating brick can be used as linings or as thermal preservation layers in various industrial furnaces and kilns in metallurgical industry, ceramic industry, chemical industry, machinery industry.

such as blast furnace, hot blast stoves ,electric arc furnace, cement kiln,melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other thermal industrial equipment.

- Q: Can insulating fire bricks be used in solar power plants?

- Yes, insulating fire bricks can be used in solar power plants. They are commonly used in the construction of high-temperature equipment such as solar receivers, combustion chambers, and thermal energy storage systems. Insulating fire bricks help to minimize heat loss and maintain high operating temperatures, making them suitable for various applications in solar power plants.

- Q: Material and making method of light insulating brick

- Material production of ordinary light insulating brick clay, high alumina high strength low iron bead brick, mullite, high aluminum light insulating refractory brick, diatomite insulating refractory brick.

- Q: Can insulating fire bricks be used in electric furnaces?

- Yes, insulating fire bricks can be used in electric furnaces. Insulating fire bricks are designed to have low thermal conductivity, which makes them ideal for use in applications where heat needs to be contained or insulated. Electric furnaces require insulation to prevent heat loss and improve energy efficiency. Insulating fire bricks can withstand high temperatures and provide excellent insulation properties, making them suitable for use in electric furnaces. Additionally, they are lightweight and easy to install, making them a preferred choice for insulation in electric furnaces.

- Q: Are insulating fire bricks resistant to oil and gas?

- Insulating fire bricks typically offer resistance against oil and gas. These bricks are crafted from high temperature materials like alumina and silica, which grant exceptional thermal insulation qualities and can endure elevated temperatures. They are commonly employed in industries where exposure to heat occurs, such as furnaces, kilns, and fireplaces. Nevertheless, it is crucial to acknowledge that the resistance to oil and gas can vary depending on the precise composition and manufacturing process of the insulating fire bricks. Certain bricks may exhibit higher resistance to oil and gas compared to others. To guarantee the utmost resistance to oil and gas, it is recommended to utilize insulating fire bricks that are specifically engineered for such applications. These bricks are often known as oil and gas resistant fire bricks and are formulated with supplementary additives or coatings that enhance their resistance to these substances. In conclusion, although insulating fire bricks generally offer resistance to oil and gas, it is advisable to employ bricks that are specifically tailored for such applications to ensure optimal performance and longevity.

- Q: Can insulating fire bricks be used in boilers for steam generation?

- Boilers can utilize insulating fire bricks for steam generation. These bricks are composed of lightweight materials, such as ceramic fibers or expanded clay, that possess exceptional insulation properties. Their low thermal conductivity ensures effective heat transfer prevention. The insulation within boilers is crucial for minimizing heat loss and enhancing energy efficiency. Insulating fire bricks can be utilized to line the boiler combustion chamber's walls, roof, and floor. By creating a highly insulating barrier, they retain heat within the chamber, enabling more efficient steam generation. Additionally, insulating fire bricks possess the ability to withstand high temperatures, making them suitable for boilers that involve elevated temperature steam generation. They also exhibit resistance to thermal shock, which is significant in scenarios where temperature fluctuations can arise. In conclusion, insulating fire bricks offer considerable advantages for boiler applications. They provide exceptional insulation, can endure high temperatures, and contribute to enhanced energy efficiency in steam generation.

- Q: Are insulating fire bricks chemically resistant?

- Yes, insulating fire bricks are chemically resistant. They are composed of high-temperature materials that can withstand harsh chemical environments without undergoing significant chemical reactions or degradation. This resistance makes them suitable for various industrial applications where exposure to chemicals is a concern.

- Q: What material is good for indoor thermal insulation?

- Own home, if the south, hot summer and cold winter zone, with inorganic insulation mortar or polystyrene particles insulation mortar, the effect is very good;

- Q: Can insulating fire bricks be used in the construction of combustion chambers for rocket engines?

- Yes, insulating fire bricks can be used in the construction of combustion chambers for rocket engines. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. This makes them ideal for applications where extreme heat is involved, such as the combustion chambers of rocket engines. The primary purpose of insulating fire bricks in a rocket engine's combustion chamber is to protect the surrounding structure from the intense heat generated during combustion. By providing insulation, these bricks help to minimize heat transfer to the outer walls of the combustion chamber, preventing damage and ensuring structural integrity. Furthermore, insulating fire bricks are lightweight and have low thermal conductivity, allowing them to effectively retain heat within the combustion chamber. This is crucial for maintaining high combustion efficiency and optimizing rocket performance. In addition to their thermal properties, insulating fire bricks are also known for their durability and resistance to thermal shock. This is particularly important in rocket engine applications where rapid temperature changes can occur, such as during ignition or shutdown sequences. The ability of insulating fire bricks to withstand such thermal stresses is essential for the reliability and longevity of the combustion chamber. Overall, insulating fire bricks are a suitable choice for the construction of combustion chambers in rocket engines due to their high-temperature resistance, thermal insulation capabilities, lightweight nature, and durability.

- Q: Can insulating fire bricks be used in the construction of kilns?

- Yes, insulating fire bricks can be used in the construction of kilns. Their high insulating properties help to retain heat and improve energy efficiency in the kiln, making them a popular choice for lining the walls and floor of kilns.

- Q: Can insulating fire bricks be used in biomass power plants?

- Insulating fire bricks possess the capability to be utilized within biomass power plants. Specifically designed to endure extreme temperatures and offer insulation, these fire bricks are well-suited for an array of applications in high-temperature settings, including biomass power plants. These power plants generate electricity by incinerating biomass materials such as wood chips, agricultural waste, and other organic substances. The usage of insulating fire bricks can span across multiple areas within a biomass power plant. Primarily, they can be employed to line the combustion chamber where the biomass is burned, releasing heat. The insulating properties of these bricks aid in containing the heat within the combustion chamber, thereby enhancing the efficiency of the biomass combustion process. Furthermore, insulating fire bricks serve a purpose in the construction of the plant's boiler, responsible for converting the heat produced by the biomass incineration into steam. The bricks can be utilized to line the walls and roof of the boiler, delivering thermal insulation and preventing heat loss. This insulation serves to maintain high temperatures inside the boiler, which is vital for steam generation and subsequent power production. Moreover, the construction of the chimney or flue system of biomass power plants can also incorporate insulating fire bricks. These bricks can be utilized to line the interior of the chimney, ensuring that the high temperatures and corrosive gases resulting from biomass combustion are safely contained and directed out of the plant. In summary, insulating fire bricks are an exceptional choice for biomass power plants due to their ability to withstand high temperatures and provide thermal insulation. Their utilization in the combustion chamber, boiler, and chimney systems contributes to the improvement of efficiency and safety in biomass power generation.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Fire Brick for Heating Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords