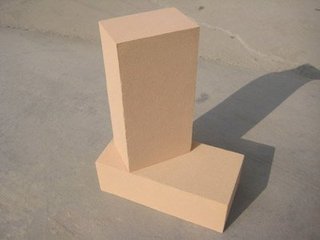

High Quality Insulating Fire Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 brick insulation material

Thermal insulation brick is a kind of polymer material synthesis of a new type of materials used.

2 insulation brick is introduced

A, fully replace aluminous model board, honeycomb panel, curtain wall, such as common decoration materials, multi-functional integration, a construction can solve the heat preservation decoration two functional requirements, level off is smooth and beautiful adornment sex is strong.

2, high strength, good rigidity, light seismic and wind resistance, creep, superior performance, reduce building load and more economic and durable.

Three fire retardant, heat preservation and heat insulation, sound insulation, heat insulation, anti-cracking waterproof, according to 65% of building energy efficiency requirements for construction design.

Four Jin Anhua, easy installation and finishing products, process, shorten the construction period and quality easy to control.

Five, don't use aluminum, steel, keel support, set in the installation, reduce the gap between the insulation board and wall body.Increased security system.

Six, no radiation, green environmental protection, can be widely used in all kinds of public buildings and home interior decoration.

Seven, installed with cement, save a lot of material, manpower and time.Reduce the air pollution caused by production cement burning, accord with the requirement of green low carbon environmental protection.

Eight, more than 70 carrier lifetime, more than 20 years of decoration life for a long time, to adapt to a variety of areas such as zha climate and complex environment.With the quality of class international aluminous model board, aluminum veneer and steel hanging stone, compared to reduce bearing 30% to 90%

Nine, double efficacy, shorten time limit, the comprehensive cost declined from 30% to 70%.

- Q: Are insulating fire bricks suitable for use in glass melting furnaces?

- Yes, insulating fire bricks are suitable for use in glass melting furnaces. Insulating fire bricks have high thermal resistance and low thermal conductivity, making them ideal for retaining heat and preventing heat loss in the furnace. Additionally, their lightweight and porous nature allow for efficient energy utilization and reduced fuel consumption.

- Q: Do insulating fire bricks require a curing period before use?

- Yes, insulating fire bricks typically require a curing period before use. This is because during the manufacturing process, these bricks are exposed to high temperatures which can cause the release of moisture and volatile compounds. Curing involves slowly heating the bricks to gradually remove any remaining moisture and volatile substances. This process helps to ensure that the bricks are fully dried and stabilized before they are subjected to the intense heat of a fire. The curing period can vary depending on the type and thickness of the bricks, but it generally involves gradually increasing the temperature over several days or weeks. Failure to properly cure insulating fire bricks can lead to cracking, spalling, and reduced thermal efficiency. Therefore, it is important to follow the manufacturer's recommendations and allow for an appropriate curing period before using these bricks in high-temperature applications.

- Q: Are insulating fire bricks suitable for use in cement plants?

- Yes, insulating fire bricks are suitable for use in cement plants. They are commonly used in high-temperature applications, such as kilns and furnaces, due to their excellent thermal insulation properties and ability to withstand extreme heat. Insulating fire bricks can help optimize energy efficiency, reduce heat loss, and provide a more controlled and stable environment in cement plants.

- Q: Can insulating fire bricks be used in the construction of foundry molds?

- Yes, insulating fire bricks can be used in the construction of foundry molds. Insulating fire bricks are made from lightweight materials such as clay, alumina, and silica, and are designed to have low thermal conductivity. This makes them ideal for applications that require high temperature resistance and insulation, such as foundry molds. Foundry molds are used to shape and hold molten metal during casting processes. Since molten metal is typically poured at extremely high temperatures, it is important to use materials that can withstand the heat without melting or deforming. Insulating fire bricks have a high melting point and excellent thermal stability, which makes them suitable for use in foundry molds. In addition to their high temperature resistance, insulating fire bricks also provide good insulation properties. This is important in foundry molds as it helps to control the cooling rate of the molten metal, preventing thermal shock and ensuring proper solidification. The insulation properties of insulating fire bricks can also help to reduce energy consumption and improve the overall efficiency of the foundry process. Overall, insulating fire bricks are a durable and efficient choice for constructing foundry molds. They offer high temperature resistance, excellent thermal stability, and good insulation properties, making them a reliable option for use in the demanding conditions of foundry operations.

- Q: What are the types of building blocks?

- Ordinary housing: building brick (clay brick), and non sintered brick (sand lime brick, fly ash brick, cement brick, etc.)

- Q: Are insulating fire bricks easy to handle and install?

- Insulating fire bricks are generally easy to handle and install. They are lightweight, making them easy to transport and carry around. Additionally, their shape and size are designed to be user-friendly, allowing for easy manipulation and installation. Most insulating fire bricks come with pre-drilled holes or grooves, which further simplifies the installation process. Moreover, these bricks can be easily cut or shaped to fit specific dimensions or requirements, making them highly versatile. Overall, insulating fire bricks are considered easy to handle and install, even for individuals with limited experience or knowledge in masonry work.

- Q: Can insulating fire bricks be used in the construction of thermal oxidizers?

- Certainly, thermal oxidizers can utilize insulating fire bricks in their construction. The remarkable thermal insulation properties of these bricks render them perfect for situations where precise containment of elevated temperatures is necessary. Thermal oxidizers function by incinerating volatile organic compounds (VOCs) at high temperatures, and the incorporation of insulating fire bricks aids in preserving the essential temperature within the combustion chamber and minimizing heat dissipation to the surroundings. Furthermore, the lightweight nature, durability, and impressive resistance to thermal shock exhibited by insulating fire bricks further enhance their appropriateness for deployment in thermal oxidizers.

- Q: Can insulating fire bricks be cut to size?

- Indeed, it is possible to alter the dimensions of insulating fire bricks. Usually composed of lightweight refractory substances like expanded clay or vermiculite, insulating fire bricks are quite manageable to cut. Saws or knives are sufficient tools for this task. It is crucial to bear in mind that precautions should be taken while cutting insulating fire bricks to ensure safety. Wearing protective goggles and a dust mask is recommended due to the potential dust and small particles generated during the cutting process. Furthermore, it is advisable to either refer to the manufacturer's instructions or seek professional guidance to guarantee the correct technique and tools are employed for cutting insulating fire bricks.

- Q: Can insulating fire bricks be used in high-temperature insulation applications?

- Indeed, high-temperature insulation applications can employ insulating fire bricks. These bricks are specifically engineered to endure and preserve heat in elevated temperatures. With their low thermal conductivity and exceptional insulation capabilities, they prove to be the perfect choice for containing and insulating high temperatures. Their widespread usage can be observed in industries like steel, glass, and ceramics, as well as in furnaces, kilns, and other equipment operating at extreme temperatures. By effectively retaining heat and minimizing energy loss, insulating fire bricks offer a dependable and efficient insulation solution for high-temperature environments.

- Q: Are insulating fire bricks resistant to alkali vapor attack?

- Insulating fire bricks are known for their general resistance to alkali vapor attack. They are crafted from high-quality refractory materials like fire clay or silica, which possess exceptional resistance to chemical assaults, including alkali vapor. These bricks are engineered to endure extreme temperatures and challenging surroundings, rendering them suitable for applications where alkali vapor may be present, such as in industrial furnaces, kilns, and incinerators. However, the level of resistance may vary depending on the specific composition and manufacturing process employed for these insulating fire bricks. To ensure compatibility with alkali vapor exposure, it is advisable to refer to the manufacturer's specifications or seek expert advice.

Send your message to us

High Quality Insulating Fire Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords