Insulating Fire Brick - Refractory JM Mullite Insulation Brick JM-26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory mullite insulating refractory brick JM 23

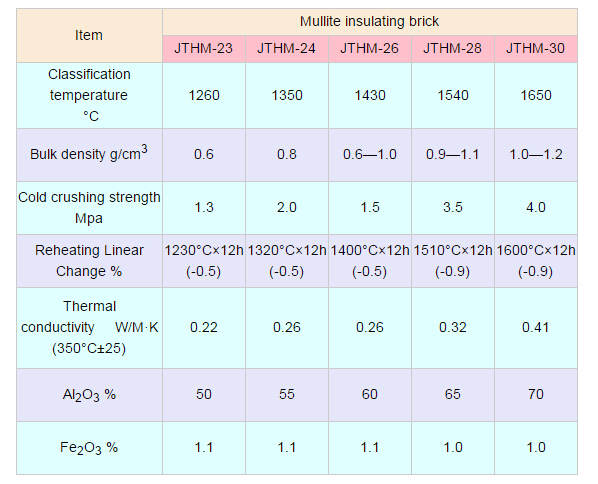

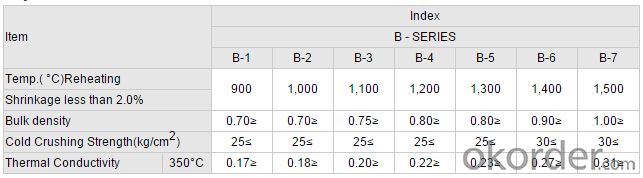

Okorder series heat insulation brick

Okorder series thermal insulation brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. Okorder series products are best Li Ning and insulation in all types of industrial furnaces in the metallurgical field, aluminum, petrochemical, electric power and glass ceramic materials. They can be used as part of the working layer of thermal insulation or non - melting. Products have been widely used in the following furnace, achieved satisfactory results.

Application of heat preservation brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen production furnace, primary reformer, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc..

Advantages of heat insulation brick

Low thermal conductivity: more porosity will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage to absorb more heat, energy-saving effect is obvious.

Gao Chundu: iron, alkali metal impurity content is low.

The precise size: Brick size processing precision, special shape cutting and grinding, accelerate the brickwork.

Insulating brick picture

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

- Q: Are insulating fire bricks resistant to chemical attack?

- Yes, insulating fire bricks are generally resistant to chemical attack. These bricks are made from high-purity refractory materials, such as alumina or silica, which have excellent chemical stability. They are designed to withstand high temperatures and are thus highly resistant to the corrosive effects of chemicals. However, it is important to note that the degree of chemical resistance can vary depending on the specific composition of the insulating fire brick and the type of chemical being used. In some cases, certain aggressive chemicals may still cause some degree of degradation or erosion over time. Therefore, it is always recommended to consult the manufacturer or supplier for specific information regarding the chemical resistance of insulating fire bricks in relation to the intended application.

- Q: Are insulating fire bricks resistant to fluorine gas?

- Typically, insulating fire bricks do not possess resistance against fluorine gas. Known for its high reactivity and corrosiveness, fluorine gas has the capability to react with diverse substances, including insulating fire bricks. The corrosive properties of fluorine gas may result in structural and integrity harm to the fire bricks, eventually leading to their degradation or malfunction. Hence, it is recommended to opt for an alternative refractory material that is specifically engineered to endure the corrosive impact of fluorine gas, in case it is needed for a specific application.

- Q: Can insulating fire bricks be used in the construction of pottery ovens?

- Yes, insulating fire bricks can be used in the construction of pottery ovens. Insulating fire bricks are specifically designed to have excellent thermal properties, such as low thermal conductivity and high resistance to heat. These qualities make them ideal for insulating and retaining heat in pottery ovens, allowing for more efficient and controlled firing of clay and ceramic materials. Additionally, insulating fire bricks are lightweight, which makes them easier to handle and install in the construction process. Overall, the use of insulating fire bricks in pottery ovens helps to create a consistent and even distribution of heat, resulting in improved firing outcomes and energy efficiency.

- Q: Can insulating fire bricks be used in the construction of furnaces?

- Insulating fire bricks are indeed suitable for the construction of furnaces. These bricks possess exceptional insulation qualities, enabling them to endure high temperatures without significant heat loss. Their composition primarily consists of lightweight materials like clay, silica, and alumina. Consequently, they exhibit low thermal conductivity, allowing the furnace to retain heat efficiently while preventing excessive heating of its outer surface. As a result, these bricks are ideal for lining the walls, roof, and floor of furnaces, contributing to enhanced energy efficiency and reduced fuel consumption. Moreover, their resistance to thermal shock ensures their durability and longevity in the demanding conditions of a furnace. In conclusion, considering their exceptional insulation properties and capacity to withstand high temperatures, insulating fire bricks remain a preferred option for furnace construction.

- Q: Can insulating fire bricks be used in the construction of furnaces?

- Yes, insulating fire bricks can be used in the construction of furnaces. These bricks are specifically designed to withstand high temperatures and provide excellent insulation, making them ideal for lining the walls of furnaces. They help to reduce heat loss, increase energy efficiency, and improve overall performance of the furnace.

- Q: How do insulating fire bricks contribute to energy efficiency?

- Insulating fire bricks are a type of brick with high thermal resistance, which means they are excellent at preventing heat transfer. This property makes them a valuable component in energy-efficient systems. One way insulating fire bricks contribute to energy efficiency is by reducing heat loss. These bricks have low thermal conductivity, which means they don't easily conduct heat. As a result, they can effectively insulate areas where high temperatures are present, such as furnaces, kilns, and fireplaces. By minimizing heat loss, insulating fire bricks help keep the heat generated in these systems contained, allowing them to operate more efficiently. Moreover, insulating fire bricks also help reduce energy consumption. As they limit heat transfer, less energy is required to maintain the desired temperature within a system. This is particularly important in industries where high temperatures are essential for operations, as it can lead to significant energy savings. By using insulating fire bricks, companies can reduce their energy consumption, resulting in lower utility bills and a reduced environmental impact. Additionally, insulating fire bricks contribute to energy efficiency by improving the overall performance of heating systems. By providing insulation, these bricks help maintain a consistent and controlled temperature within the system. This ensures that the heat is evenly distributed and that there are no energy wastages due to temperature fluctuations. As a result, systems equipped with insulating fire bricks can operate more efficiently and effectively. In conclusion, insulating fire bricks play a crucial role in enhancing energy efficiency. Their high thermal resistance properties help reduce heat loss, minimize energy consumption, and optimize the performance of heating systems. By incorporating insulating fire bricks, individuals and industries can enjoy significant energy savings while also promoting a greener and more sustainable approach to energy consumption.

- Q: Are insulating fire bricks suitable for insulation in power boilers?

- Insulating fire bricks may be appropriate for insulating power boilers depending on the boiler's specific needs and conditions. Insulating fire bricks are renowned for their resistance to high temperatures and low thermal conductivity, resulting in enhanced energy efficiency and reduced heat loss in various applications. However, when contemplating their utilization in power boilers, several factors must be taken into consideration. Firstly, the boiler's operating temperature and pressure must be evaluated to ensure that the insulating fire bricks can endure these conditions without any degradation or failure. Power boilers typically operate under high temperatures and pressures, necessitating the selection of insulating fire bricks with a high temperature rating and the ability to withstand the required pressure. Furthermore, the composition and structure of the insulating fire bricks should be accounted for. Some power boilers may contain corrosive or abrasive substances that could potentially damage the insulating fire bricks over time. As a result, it is imperative to choose insulating fire bricks that are resistant to corrosion and abrasion, or to consider additional protective measures such as coatings or linings. Additionally, the thermal conductivity of the insulating fire bricks should be assessed. Although insulating fire bricks have lower thermal conductivity compared to other refractory materials, it is crucial to ensure that they provide adequate insulation for the power boiler's specific requirements. This may involve calculating heat transfer rates and determining the appropriate thickness and density of the insulating fire bricks to achieve the desired insulation performance. Ultimately, the suitability of insulating fire bricks for insulation in power boilers is contingent upon careful consideration of factors such as temperature, pressure, composition, structure, and thermal conductivity. Seeking guidance from experts and conducting thorough evaluations and calculations will assist in determining whether insulating fire bricks are a suitable choice for insulation in a particular power boiler application.

- Q: Can insulating fire bricks be used in wastewater treatment plants?

- Indeed, insulating fire bricks have the capability to be utilized within wastewater treatment plants. Specifically engineered to endure extreme temperatures, insulating fire bricks are fitting for a variety of industrial applications, including wastewater treatment plants. They are commonly implemented in constructing kilns, furnaces, and other equipment that operates at high temperatures. Within wastewater treatment plants, insulating fire bricks can be incorporated into the assembly of incinerators, thermal oxidizers, and other systems that necessitate high-temperature insulation. Their exceptional properties, such as remarkable thermal resistance, minimal thermal conductivity, and exceptional insulation abilities, make them an ideal choice for maintaining the desired temperatures in these systems while simultaneously diminishing heat loss. Moreover, insulating fire bricks demonstrate resistance to chemical attacks, a vital characteristic within wastewater treatment plants that handle a plethora of chemicals and corrosive substances. In summary, the utilization of insulating fire bricks in wastewater treatment plants can lead to enhanced energy efficiency, reduced maintenance expenses, and the assurance of longevity for high-temperature equipment.

- Q: Which kind of balcony heat preservation material is better?

- To environmental protection, then use inorganic insulation materials, such as composite silicate, rare earth insulation, this thickness should be more than 5 cm, the construction of auxiliary materials, high cost, to be strengthened

- Q: Are insulating fire bricks suitable for insulation in chemical reactors?

- Due to their exceptional thermal properties and resistance to high temperatures, insulating fire bricks are commonly employed for insulation in chemical reactors. These bricks, which are manufactured from lightweight refractory materials like alumina, silica, and other minerals, effectively impede heat transfer and provide insulation. Furthermore, they possess low thermal conductivity and high heat capacity, enabling them to minimize heat loss and maintain consistent temperatures within the reactor. Chemical reactors often operate at elevated temperatures and may contain corrosive or reactive substances. Insulating fire bricks can withstand these harsh conditions and safeguard the reactor against external heat sources. They are chemically inert and corrosion-resistant, making them suitable for use with various chemicals and reactants. Additionally, insulating fire bricks exhibit a low thermal expansion coefficient, allowing them to endure thermal cycling without cracking or distorting. This characteristic is crucial in chemical reactors where temperature fluctuations are frequent and can potentially harm the equipment. In conclusion, insulating fire bricks are a popular choice for insulation in chemical reactors due to their thermal insulation properties, resistance to chemicals, and ability to withstand high temperatures and thermal cycling. Their usage aids in enhancing the efficiency and safety of chemical processes by maintaining optimal operating conditions within the reactor.

Send your message to us

Insulating Fire Brick - Refractory JM Mullite Insulation Brick JM-26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords