Insulating Fire Brick GJM30 in Lightweight Fireclay - Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Insulating Brick

CMAX Insulating Brick are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Features of Insulating Brick

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Specifications for Insulating Fire Brick

Applications of Insulating Brick

CMAX Insulating Brick can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Specifications of Insulating Brick

Type No. |

Density |

Compressive Strength |

Rupture Strength | % Linear Change on Reheating | Thermal Shock Resistance, Times | Heat Conductive Cofficient | Al2O3 | Fe2O3 |

DJM-23 | 0.60 | 1.3 | 1.0 | 1230×12-0.5 | ≥20 | 400°C0.15 | 40 | 0.70 |

DJM-26 | 0.80 | 1.8 | 1.4 | 1400×12-0.5 | >20 | 600°C0.25 | 55 | 0.70 |

DJM-28 | 0.90 | 2.2 | 1.7 | 1510×12-1.0 | >20 | 600°C0.34 | 65 | 0.60 |

DJM-30 | 1.0 | 2.50 | 2.10 | 1600×12-1.0 | >20 | 600°C0.43 | 74 | 0.50 |

DJM-32 | 1.2 | 3.50 | 2.50 | 1650×12-1.0 | >20 | 600°C0.50 | 76 | 0.40 |

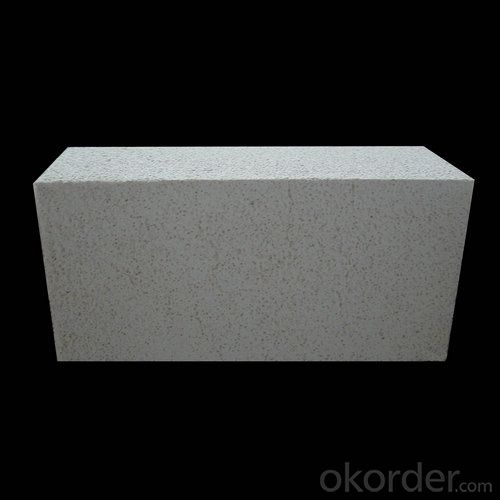

Images of Insulating Brick

FAQ of Insulating Brick

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a general idea of the specification and technical data of your products?

CNBM offer a range of refractory and insulation products. We provide refractory bricks, monolithic refractories as well as ceramic fiber products. And On your given shapes, drawings or description, we are producing refractories with all sizes and shapes, resistant to temperature from 800 °C till 1800 °C, using various machines and equipments for cutting, grinding, drilling, polishing, shaping processes.

Every refractory product by CNBM is of superior quality. Lesser refractory products can not approach. CNBM utilizes proprietary testing methods, testing for chemical content, density, apparent porosity, cold crush strength and modulus of rapture. With stringent quality control, you can count on CNBM products to exceed refractory industry standards and your expectations.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Are insulating fire bricks suitable for use in glass melting furnaces?

- Insulating fire bricks can be suitable for use in glass melting furnaces, depending on the specific requirements of the furnace and the type of glass being melted. Insulating fire bricks are made from lightweight materials with low thermal conductivity, which makes them effective at retaining heat and reducing energy loss in the furnace. This can help improve the energy efficiency of the furnace and reduce operating costs. However, it is important to consider the temperature and atmosphere inside the glass melting furnace when choosing the type of insulating fire bricks. Glass melting furnaces operate at extremely high temperatures, often exceeding 1500°C (2732°F). Some insulating fire bricks may not be able to withstand such high temperatures and could degrade or even melt under these conditions. Additionally, the atmosphere inside the glass melting furnace can have an impact on the suitability of the insulating fire bricks. Some types of insulating fire bricks may react with certain gases or chemicals present in the furnace atmosphere, leading to degradation or contamination of the glass being melted. Therefore, it is crucial to select insulating fire bricks that are compatible with the specific atmosphere and conditions inside the glass melting furnace. In summary, insulating fire bricks can be suitable for use in glass melting furnaces, but careful consideration must be given to their temperature resistance and compatibility with the furnace atmosphere. Consulting with experts or suppliers who specialize in refractory materials for glass melting furnaces can help ensure the appropriate selection of insulating fire bricks for optimal furnace performance and glass quality.

- Q: Can insulating fire bricks be used in high-temperature insulation for aerospace applications?

- Yes, insulating fire bricks can be used in high-temperature insulation for aerospace applications. These bricks are designed to withstand extremely high temperatures and provide excellent insulation properties, making them suitable for use in aerospace applications where thermal protection is crucial.

- Q: Can insulating fire bricks be used for insulation in cold storage facilities?

- Yes, insulating fire bricks can be used for insulation in cold storage facilities. Insulating fire bricks are made from lightweight materials with high insulating properties, such as ceramic or refractory fibers. They have low thermal conductivity, which means they can effectively prevent heat transfer and maintain a stable temperature inside the cold storage facility. The bricks are also resistant to extreme cold temperatures and can withstand thermal shock, making them suitable for use in cold storage applications. Additionally, insulating fire bricks are durable and can provide long-term insulation, reducing energy consumption and maintaining the desired temperature for storing perishable goods.

- Q: Are insulating fire bricks resistant to alkali attack?

- Yes, insulating fire bricks are generally resistant to alkali attack. These bricks are made from high-temperature refractory materials and are designed to withstand extreme temperatures and chemical environments. Alkalis are known to corrode and degrade certain materials, but insulating fire bricks are specifically formulated to resist this type of chemical attack. They have a low porosity and dense structure, which helps prevent the penetration of alkalis into the brick's surface. Additionally, the refractory materials used in these bricks have a high melting point and are chemically inert, making them well-suited for applications where alkali exposure is a concern. However, it is important to note that the specific resistance of insulating fire bricks to alkali attack may vary depending on the composition and manufacturing process of the brick, as well as the concentration and duration of alkali exposure. Therefore, it is always recommended to consult with the manufacturer or supplier for detailed information about the resistance of their specific insulating fire bricks to alkali attack.

- Q: Can insulating fire bricks be used in cement plants?

- Yes, insulating fire bricks can be used in cement plants. Insulating fire bricks are designed to withstand high temperatures and are commonly used in industries that require thermal insulation. In cement plants, they can be used in various applications such as lining kilns, furnaces, and other high-temperature equipment. These bricks help in reducing heat loss, improving energy efficiency, and ensuring consistent and controlled temperatures in the cement production process. Additionally, insulating fire bricks are lightweight and have low thermal conductivity, making them an ideal choice for insulating applications in cement plants.

- Q: Can insulating fire bricks be used in high-temperature insulation panels?

- Yes, insulating fire bricks can be used in high-temperature insulation panels. Insulating fire bricks are designed to withstand and retain heat, making them an ideal choice for applications that require high-temperature insulation.

- Q: Can insulating fire bricks be used in the construction of combustion flues?

- Yes, insulating fire bricks can be used in the construction of combustion flues. Insulating fire bricks are designed to withstand high temperatures, making them ideal for use in environments where heat resistance is required. Combustion flues are exposed to extreme heat and gases generated during combustion, and insulating fire bricks can help protect the flue structure from the intense heat and prevent heat loss. Additionally, these bricks have low thermal conductivity, meaning they are effective in insulating and retaining heat within the flue. This can help improve the efficiency of the combustion process and minimize energy waste. Overall, the use of insulating fire bricks in the construction of combustion flues can enhance safety, efficiency, and longevity of the flue system.

- Q: Can insulating fire bricks be used in the construction of steam generators?

- Indeed, the utilization of insulating fire bricks is possible in the construction of steam generators. Specifically engineered to possess superior thermal insulation properties, these bricks are well-suited for applications necessitating elevated temperatures and thermal stability. Given that steam generators function at high temperatures and necessitate efficient heat transfer, insulation becomes indispensable for preventing heat dissipation and enhancing energy efficiency. By enduring extreme temperatures and offering effective insulation, insulating fire bricks diminish heat losses and enhance the overall effectiveness of steam generators. Furthermore, their lightweight composition facilitates easy handling and installation during the construction process. Therefore, insulating fire bricks represent a fitting choice for the construction of steam generators.

- Q: Can insulating fire bricks be used for insulation in boilers?

- Certainly, insulation in boilers can make use of insulating fire bricks. These bricks are specially engineered to endure extreme temperatures and offer exceptional thermal insulation. Their thermal conductivity is minimal, resulting in a significant decrease in heat dissipation and an enhancement in the energy efficacy of boilers. Moreover, insulating fire bricks are lightweight and simple to install, rendering them a favored option for boiler insulation. They aid in preserving elevated temperatures within the boiler, facilitating efficient combustion and heat transfer, while simultaneously shielding the outer framework from excessive heat. All in all, insulating fire bricks are a dependable and efficient alternative for boiler insulation.

- Q: Can insulating fire bricks be used in hydrogen furnaces?

- Insulating fire bricks can be used in hydrogen furnaces, but it is important to note that not all types of insulating fire bricks are suitable for this application. Hydrogen is a highly reactive gas and can cause certain materials to degrade or react, leading to safety concerns and potential damage to the furnace. When selecting insulating fire bricks for use in hydrogen furnaces, it is crucial to choose bricks that are specifically designed for high-temperature and corrosive environments. These bricks should be made from materials that are resistant to hydrogen embrittlement and have low reactivity with hydrogen. Silicon carbide (SiC) and alumina-silica (Al2O3-SiO2) are commonly used materials for insulating fire bricks in hydrogen furnaces. These materials have good resistance to high temperatures and are chemically stable in the presence of hydrogen. It is also important to consider the density and porosity of the insulating fire bricks. Low-density bricks with high porosity are preferred for hydrogen furnaces as they provide better thermal insulation and reduce the risk of hydrogen leakage. Overall, while insulating fire bricks can be used in hydrogen furnaces, it is crucial to select the appropriate type of bricks that are specifically designed for high-temperature and corrosive environments, and have good resistance to hydrogen embrittlement and reactivity. Consulting with experts in the field and following the manufacturer's guidelines is highly recommended to ensure the safe and efficient operation of the hydrogen furnace.

Send your message to us

Insulating Fire Brick GJM30 in Lightweight Fireclay - Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords