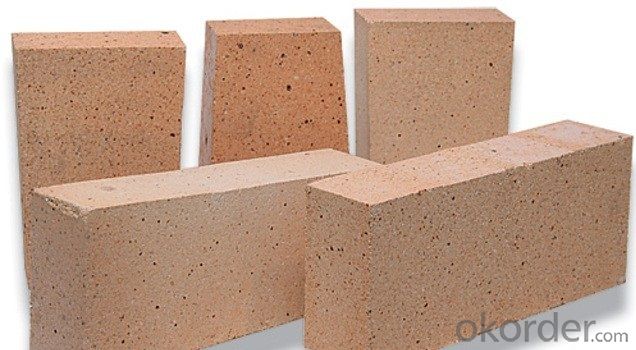

Fireclay Brick - Lightweight Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | SiO2 Content (%): | 0 |

| Al2O3 Content (%): | 0 | MgO Content (%): | 0 | CaO Content (%): | 0 |

| Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 | SiC Content (%): | 0 |

| Model Number: | BB004 | Brand Name: | Beixing/ BRCC | color: | red |

| condition: | new | weight: | 0.5kg | max. service tem.: | 1350°c |

| application: | industry furnance | After-sales Service Provided: | yes | Warranty: | 1 year |

| shape: | brick | materials: | clay & hollow sphere |

Packaging & Delivery

| Packaging Details: | Normally,1000kg or1100kg into a pallet,each piece is isolated by good padpaper,or bubble film,or foam board,etc..Outside,with tight shrink film wrapping around and anti collision bars&big fiber board in sides. The customized package is available. |

| Delivery Detail: | 1 week |

Product Description

Specifications

1.Insulating firebrick

2. Low density

3. Low thermal conductivity

4. Good thermal insulation performance

Technical parameter

Type (item) | GG0.8 | GG0.7 | GG0.6 | GG0.5 | GG0.4 |

Density g/cm3≤ | 0.8 | 0.7

| 0.6 | 0.5 | 0.4 |

Compressive strength Mpa≥ | 2.5 | 2.0 | 1.0 | 0.8 | 0.5 |

thermal conductivity 350°C±25 °C W/m.k

| 0.21 | 0.20 | 0.17 | 0.16 | 0.13 |

linear change on reheating≤2%×8h Lab Temperature °C | 900 | ||||

Definition:

It is a kind of the light weight refractory products which contains the alumina content range from 10% to 15%.

Production process:

Ingredients and water mixed together made the plastic pug or slurry, then Extruded-Form or moulding by casting, dry, and firing in the 1250-1350°Coxidizing atmosphere.

Application:

Mainly used as thermal insulating layer without the liquid melt touched or gas pickling in the constructing the various industry furnaces.

- Q: What are the release agents of refractory bricks?

- Alkalinity, the production process of alkaline, acid and alkali resistant transparent instant thickening powder, you can adjust the proportion according to the cost and needs of quality, environmental protection: One: Add the preservative into water to mix, after soaking one hour, then mixing evenly the production ratio, and then add the super core release agent into water to mix, add flavor pigment masterbatch into water to mix with water mixing, ensure completely dissolved, then add the waste oil, falvor is appropriate amount= release agent. Two, the newest recipe of release agent super core release agent masterbatch, waste engine oil, water, instant acidproof and alkaliproof transparent thickening powder, wire drawing powder, preservative, flavor and pigment= release agent super core wire drawing powder with water mixing, it is the most newly developed special core masterbatch and engine oil of Chengdu Hengfeng Hongye detergent factory, and it doesn't contain toxic solvents, especially 1, it has the following features, after thickening more than half an hour or so, mix evenly is ok, in a few seconds will waste oil and alkali: 10% of waste engine oil, 20% of release agent core masterbatch, 88% of water, 500g instant acidproof alkaliproof transparent thickening powder, 80g wire drawing powder, 1g pigment and preservative and lubricating oil and industrial grease, these integrate with water.

- Q: The furnace refractory bricks are burnt into ash, what material can resist higher temperature than the refractory brick

- To change a new one, it is a common way now, isn't it?

- Q: What is refractory brick? What is refractory clay? ?

- Fire clay refers to the light pouring material, raw materials adopt light porous clinker, bauxite, cenosphere, silicon dioxide ultrafine powder and alumina micropowder. Use calcium aluminate cement CA-80 as binder. Refractory brick is burned from stone powder and clay put in 1300 degrees' kiln

- Q: Can common cement mortar be used to build the lining of chimney refractory brick?

- No. You have used fire bricks, which shows there is a certain temperature inside, you'd better use refractory cement

- Q: Are refractory bricks, burner block and thermal insulation brick the same? Are they the same thing?

- The burner block is heavy, its using temperature is high, while thermal insulation brick is light and its using temperature is lower than heavy brick.

- Q: When using high alumina refractory brick, what are the reasons leading to the decline of the performance of high alumina brick?

- The excess air coefficient is controlled in 1, in order to prevent producing water cracks in the production of high aluminum refractory brick from, control the water absorption of 2 grade clinker of bauxite with high alumina below 4%-5%. 1-1,the water absorption of the tube mill should also be controlled below 6%, and adjust thermotechnical, making the high alumina refractory brick burning be in the stable weak oxidizing atmosphere. should be 2

- Q: What is sintered non clay brick?

- Unfired bricks are bricks used to build walls relative to sintered bricks.

- Q: application of phosphate refractory bricks

- The 4 properties of phosphate refractory bricks: (1) high strength wear resistance (2) and chemical erosion (its alkali resistant ability is better than that of clay brick and high alumina brick) (3) and good thermal shock resistance (4) high load softening temperature in rotary kiln, kilneye, kiln Zone door cover, cooling machine and lining refractory brick falling parts easy to loose

- Q: does the electric kiln burner need to be sealed?

- seal when open the kiln, and observe the temperature, when the temperature reaches a point, you can move the firebrick away, and continue observing the temperature to decide whether to seal it or not, but do not seal it completely, repeat the procudure until reach the sinter point or skill requirement.

Send your message to us

Fireclay Brick - Lightweight Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords