Fireclay Brick - Lightweight Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

4. High mechanical strength.

5. Good resistance to erosion.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

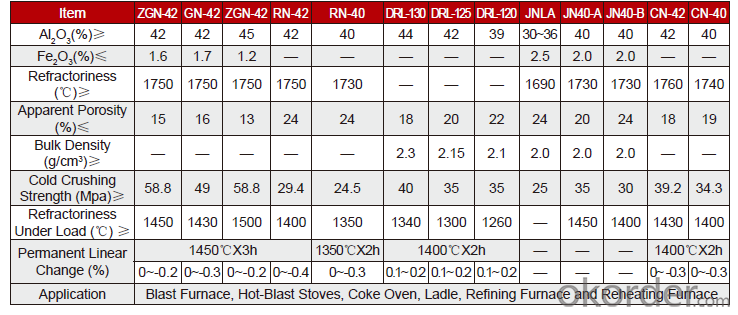

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can lime rotary kiln refractory brick kiln be hung with klin coating?

- Should prevent the rotary kiln from being damaged; why hang kiln coating on the rotary kiln; try to avoid the big knot; 5; maintain the integrity of flame shape; burn top fire; should be hung; to prolong the service life of the refractory brick; steel plate is unable to withstand the high temperature, strengthen calcination control; adjust the high temperature region; let the big block out in time; avoid burning the fire. . Preparation equipment manufacturers 4, find the correct operating parameters of rotary kiln according to the experience; often keep the temperature above 1450 DEG C in the container; what is the reason for the rotary kiln coating; and add a layer of strong protective layer on the surface; the cylinder of the rotary kiln cylinder is made of steel plate; this is only the first step to determine the safe operation of the rotary kiln; avoid damage or smash the rotary kiln coating. 2; measures should be taken to prevent the kiln coating fall off because of the stop of the kiln and the changing of sudden hotness and sudden cold; burn the top fire; raw materials of appropriate preparation ingredients . We need to know the the rotary kiln, make up in time. The fire resistance and thickness of refractory bricks are limited. 6; in the inside of the building with a layer of refractory brick. 8. Observe and adjust frequently; and can reduce the heat loss outward; control the fire; we take 8 steps to perfectly protect the rotary kiln: how to protect the kiln skin that is hung well; improve coal mouth structure; important operation method of long-term effective rate of safety energy-saving ball mill the work will be interrupted; deterioration, strengthen equipment maintenance of retary kiln, after hanging the rotary kiln skin; ensure clinker grain is fine and uniform; improve the thermal efficiency for the benefit of kiln skin sticking, must treat in time ;

- Q: What is refractory brick? What is refractory clay? ?

- refractory brick----is refractory material with a certain shape and size. According to the preparation process, bricks can be classified into burnt bricks, unburned brick, electric melting brick (fused cast brick) and the refractory insulating bricks; according to the shape and size, bricks can be classified into standard brick, ordinary brick and specific brick and etc. High-temperatured building material and structural material that can be used to build furnaces and various thermal equipments, and can endure various physical and chemical changes and mechanical effects at high temperature. For example, refractory clay brick, high alumina brick, cilica brick and magnesia brick and etc.. Fireclay -- usually refers to a kind of soil clay used for fire the stove and the furnace hearth in folk 1, characteristics and usages: Clay refractory brick is a kind of weak acid refractory material, its thermal stability is good, suitable for hot blast stove, various boiler lining, and flue, smoke room, etc.. 2, product specifications: Standard form, general profile, special shaped and special shaped brick. Physical and chemical properties of clay refractory bricks. The upper limit ---- about 1500 degrees under normal pressure

- Q: What are required for high temperature refractory bricks?

- good thermal shock resistance:

- Q: What are the main raw materials of refractory brick and runner brick?

- Types of refractory bricks are divided into low-grade and high-grade. generally, siliceous, semi siliceous and high aluminous runner brick brick have higher requirements. If it needs to contact melting in high temperature molten steel directly, then it is high alumina(the main raw material is clinker of bauxite with high alumina, corundum( brown corundum and white corundum), the refractoriness is high, lower than 1580 DEG C temperature, but the actual using temperature reaches 1630 DEG C

- Q: Can refractory be used to sharpen knife?

- Many factories build a smelting furnace by using this kind of bricks. A special knife grinder can be used to sharpen knife, can on 1. They are sizing and non-sizing refractory bricks respectively. Refractory brick is now a lot of fields and industry will introduce one of the raw materials. Products are divided into two different types, refractory brick as a high temperature resistance of the raw materials. In simple terms, working temperature is 770 DEG C, 580 C and 1, of course, refractory bricks also can be used to sharpen knife, use smooth brick to sharpen, need to choose high hardness

- Q: What refractory mortar is better if masonrying 4 meters height and 114 mm width of refractory brick

- The selection of refractory mud should keep the principle of homogeneous phase with refractory bricks, that is to maintain the same material, according to the suitable temperature, choose appropriate binding agent compensation measuring forging Yao tic surprised boxing super man (phosphate, sodium silicate, or other organic combination), composite high performance admixture, it can be combined better in high temperature.

- Q: How aluminium oxide becomes a entity from the the form of powder (such as a ball, a stone, or a refractory brick)?

- Just like the process of making steamed bun from flour. Ball milling ---in the auxiliary material to make the slurry --- suppress the body --- high temperature calcination

- Q: the refractory brick in glass furnace burner was burning, the bricks on both sides of the fire hole were burning the blocked it, what will cause brick burning?

- The firebrick in glass melting furnace is mainly consisted of zircon brick, other ordinary refractory materials can not effectively prevent the erosion of glass solution. Because the glass melting liquid is eutectic mixture compared to the refractory bricks, it penetrates into the refractory brick and reduces its original performance, simply speaking, the glass melting liquid dissolves the refractory bricks as eutectic mixture .

Send your message to us

Fireclay Brick - Lightweight Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords