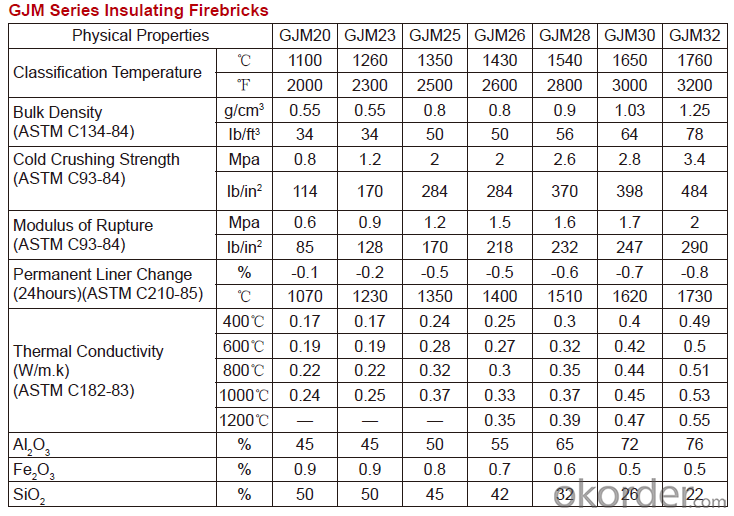

GJM 30 Light Dense Mullite Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a refractory material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment and good service

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used in sewage treatment plants?

- Yes, insulating fire bricks can be used in sewage treatment plants. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for various industrial applications, including sewage treatment plants where high temperatures may be present. Insulating fire bricks help to reduce heat loss and improve energy efficiency in these facilities.

- Q: Can insulating fire bricks be used in the construction of crucible furnaces?

- Crucible furnaces can indeed utilize insulating fire bricks. These bricks have been specifically engineered to endure extreme temperatures while providing exceptional insulation capabilities, making them a suitable choice for crucible furnace construction. Comprised of lightweight materials like alumina and silica, these bricks possess low thermal conductivity, allowing them to effectively retain heat. By incorporating insulating fire bricks, crucible furnaces can achieve heightened energy efficiency, quicker heating durations, and improved temperature regulation. Furthermore, these bricks exhibit resistance to thermal shock, guaranteeing their durability under the crucible furnace's intense heat. Overall, due to their remarkable thermal insulation properties and ability to withstand high temperatures, insulating fire bricks have gained popularity as a preferred option for constructing crucible furnaces.

- Q: Can insulating fire bricks be used in the construction of tundishes?

- Yes, insulating fire bricks can be used in the construction of tundishes. Insulating fire bricks are lightweight and have excellent thermal insulation properties, making them ideal for applications where heat retention is important. Tundishes, which are used in the steel industry to control the flow of molten metal, require materials that can withstand high temperatures and minimize heat loss. Insulating fire bricks can withstand the extreme temperatures found in tundishes, helping to maintain the desired temperature of the molten metal and preventing heat loss. Additionally, their lightweight nature makes them easier to handle and install in tundish construction. Overall, insulating fire bricks are a suitable choice for the construction of tundishes due to their thermal insulation properties and ability to withstand high temperatures.

- Q: Are insulating fire bricks suitable for insulation in steam boilers?

- Yes, insulating fire bricks are suitable for insulation in steam boilers. Insulating fire bricks are made from lightweight materials that have high insulating properties, such as alumina or silica. They are designed to withstand high temperatures and thermal shocks, making them ideal for use in steam boilers where there is constant exposure to heat. Insulating fire bricks have low thermal conductivity, which means they can effectively prevent heat transfer, reducing energy loss and increasing the efficiency of steam boilers. Their high insulation properties also help to maintain consistent temperatures within the boiler, preventing heat fluctuations and minimizing the risk of thermal stress and damage. Furthermore, insulating fire bricks are resistant to corrosion and chemical attacks, ensuring their durability and longevity in steam boiler applications. They are also easy to install and can be cut into different shapes and sizes to fit the specific requirements of the boiler. Overall, insulating fire bricks are an excellent choice for insulation in steam boilers due to their ability to withstand high temperatures, low thermal conductivity, and resistance to corrosion. They help in reducing energy loss, improving efficiency, and ensuring the longevity of the boiler.

- Q: What's the price of lightweight refractory bricks?

- In addition, general price comparisons are meaningless and need to be based on the use of demand = quality of products. After all, good quality is the driving force of continuous production.

- Q: Can insulating fire bricks be used in chimneys and flues?

- Insulating fire bricks are specifically designed for high-temperature applications and are often used in furnaces, kilns, and other industrial settings. While they do possess excellent insulating properties, they may not be the best choice for chimneys and flues in residential or commercial buildings. The main reason for this is that insulating fire bricks are not as durable and heat-resistant as other materials specifically designed for chimney and flue construction. They may crack or break when exposed to the extreme heat and rapid temperature changes that occur in chimneys. Additionally, these bricks are not typically designed to withstand the corrosive effects of flue gases, which can lead to their degradation over time. When it comes to chimneys and flues, it is generally recommended to use materials such as clay flue liners, stainless steel, or refractory bricks that are specifically manufactured for these applications. These materials are better suited to handle the high temperatures, corrosive gases, and rapid thermal expansion and contraction that occur in chimneys. It is important to consult with a professional chimney or flue specialist who can advise on the appropriate materials to use based on the specific requirements and conditions of your chimney or flue system.

- Q: Can insulating fire bricks be used for insulation in ovens and kilns?

- Insulating fire bricks are indeed suitable for insulation in ovens and kilns. These bricks are specially designed to withstand high temperatures and offer exceptional thermal insulation. They are composed of lightweight materials such as clay and other refractory substances with low thermal conductivity. Consequently, they possess the ability to effectively retain heat and prevent its escape, making them an ideal choice for ovens and kilns where heat retention is of utmost importance. Furthermore, insulating fire bricks possess resistance against thermal shock, enabling them to endure rapid temperature changes without cracking or breaking. Ultimately, insulating fire bricks guarantee efficient heat distribution and energy conservation, making them a reliable option for insulating ovens and kilns.

- Q: How do insulating fire bricks affect the overall noise reduction of a structure?

- Insulating fire bricks can significantly contribute to the overall noise reduction of a structure. These bricks have excellent sound-absorbing properties, which help in reducing the transmission of sound waves through the walls or partitions. By effectively dampening and absorbing sound vibrations, insulating fire bricks can minimize the noise pollution within a structure, creating a quieter and more peaceful environment.

- Q: What is the thermal expansion of insulating fire bricks?

- The thermal expansion of insulating fire bricks is relatively low, typically around 0.5% to 1%.

- Q: How do insulating fire bricks affect the overall fire rating of a structure?

- The overall fire rating of a structure is greatly influenced by the use of insulating fire bricks. These bricks are specifically designed to provide effective thermal insulation, thus reducing heat transfer and the risk of fire propagation. Incorporating insulating fire bricks into the construction of walls, ceilings, and floors significantly enhances the structural integrity of the building. The insulating properties of these bricks limit the spread of fire by reducing heat conduction through building materials. This is achieved through the presence of tiny air pockets within the bricks that act as insulating barriers. As a result, the temperature rise on the non-exposed side of the wall or floor is minimized, preventing the rapid spread of fire to other areas of the structure. In addition to their thermal insulation capabilities, insulating fire bricks are also highly resistant to high temperatures. This allows them to maintain their structural integrity even when exposed to intense heat, making them highly resistant to fire damage. Using these bricks in critical areas such as fire-rated walls, doors, and fireplaces significantly improves the overall fire rating of a structure. Furthermore, insulating fire bricks offer additional benefits such as soundproofing, energy efficiency, and durability. They reduce sound transmission, creating a quieter environment inside the structure. Their excellent insulation properties also minimize heat loss or gain, resulting in lower heating and cooling costs. Additionally, their resistance to thermal shock and chemical corrosion ensures a long-lasting and reliable fire barrier. To conclude, insulating fire bricks play a crucial role in enhancing the overall fire rating of a structure. Their exceptional thermal insulation properties and ability to withstand high temperatures contribute to preventing the rapid spread of fire and minimizing fire damage. Incorporating these bricks into the construction of walls, ceilings, and floors significantly improves the fire safety of a building, providing occupants with valuable evacuation time and minimizing property loss.

Send your message to us

GJM 30 Light Dense Mullite Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords