Geotextile Polypropylène ilament civil woven geotextiles continue fiber from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

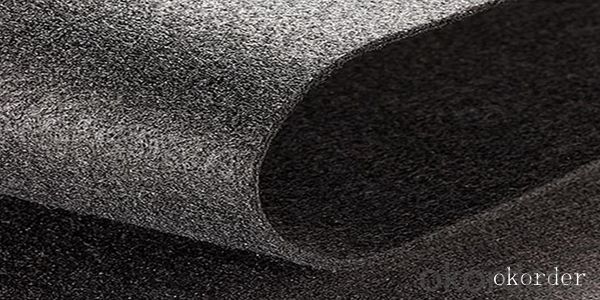

Geotextiles, Nonwoven Geotextile woven Geotextile

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

CMAX-S001

Geotextile Type:

Non-Woven Geotextiles Woven Geotextiles

Width:

1m-8m

Length:

Customer Requirment

Weight:

100g/m2-1500g/m2

Color:

White, Black, etc

Woven (Stabilization and Soil Separation Fabrics)

Polypropylene slit-film geotextiles utilized in applications such as separation of aggregate base materials and native soils in roadway construction, stabilization over soft soils and separation between dissimilar soils.

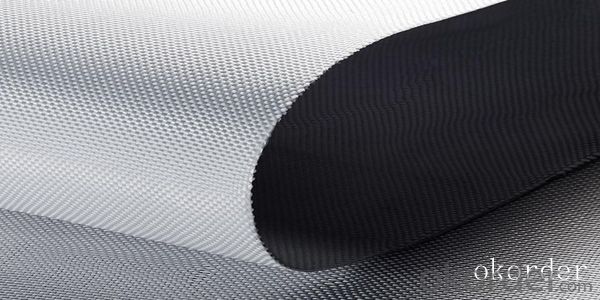

WOVEN GEOTEXTILES

1 High Performance

2 High Tensile Modulus

3 Monofilament

4 lit Film

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help in the construction of ponds and lakes?

- Geotextiles help in the construction of ponds and lakes by providing reinforcement, filtration, and erosion control. They act as a barrier between the soil and water, preventing soil erosion and promoting stability. Geotextiles also help in filtering out any fine particles or contaminants, ensuring clean and clear water. Additionally, they enhance the strength and durability of the pond or lake structure, increasing its longevity and resistance to wear and tear.

- Q: Who can talk about geogrid, fiberglass and geotextile What is the difference, from the material function, use all aspects of speaking, if the answer is good, I will add more points

- Grille is made of polypropylene, polyvinyl chloride and other polymer polymer by thermoplastic or molded two-dimensional grid or with a certain height of the three-dimensional grid grid, when used as a civil engineering, known as geotechnical Grille Engineering applications: roads, railways, abutments, approach roads, docks, dams, slag and other soft soil foundation reinforcement, retaining walls and road surface cracking engineering and other fields. Fiberglass mesh used in the external walls, wall paint, the main material to prevent the junction of different mortar and other plastering material cracking, hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Common non-woven fabrics, water layer inside the use, polyethylene polypropylene waterproof also used.

- Q: How do geotextiles aid in the reduction of settlement-induced cracking?

- Geotextiles aid in the reduction of settlement-induced cracking by providing a stable and reinforced base for construction projects. They distribute the load and enhance the soil's bearing capacity, preventing excessive settlement and subsequent cracking in the structure.

- Q: How do geotextiles help with soil stabilization in slope stabilization projects?

- Geotextiles play a crucial role in soil stabilization during slope stabilization projects. They are designed to be placed between layers of soil to enhance their structural stability. Geotextiles act as a barrier, preventing soil erosion and promoting water drainage. By providing reinforcement, they distribute the load across a wider area, reducing the pressure on the slope and minimizing the risk of landslides. Additionally, geotextiles help to retain moisture in the soil, which aids in vegetation growth, further strengthening the slope. Overall, geotextiles are an effective solution for soil stabilization in slope stabilization projects.

- Q: Can geotextiles be used in the protection of shoreline structures?

- Yes, geotextiles can be used in the protection of shoreline structures. They are commonly used to stabilize and reinforce soil, prevent erosion, control sedimentation, and provide a barrier against wave action in shoreline projects. Geotextiles provide valuable support and protection to shoreline structures such as revetments, seawalls, and breakwaters by reducing the impact of waves, preventing soil erosion, and enhancing the overall stability of the shoreline.

- Q: What are the different geotextile testing parameters?

- Some different geotextile testing parameters include tensile strength, puncture resistance, burst strength, permittivity, apparent opening size, and UV resistance.

- Q: Are geotextiles suitable for use in bridge construction?

- Yes, geotextiles are suitable for use in bridge construction. Geotextiles offer various benefits such as soil stabilization, erosion control, and drainage improvement, which are crucial for the long-term durability and performance of bridges. Additionally, geotextiles can help distribute loads and reduce stresses on the bridge structure, enhancing its overall stability.

- Q: Why do you shop the geotextile during the construction of the road

- Huazhi geotechnical materials manufacturers to answer

- Q: 3923.1 why not apply to geotextiles

- Geotextile price, geomembrane price, composite geomembrane price can be found tgcl1123 to see

- Q: What are the considerations for geotextile selection in coastal engineering projects?

- When selecting geotextiles for coastal engineering projects, several considerations need to be taken into account. First, the geotextile should have a high tensile strength and durability to withstand the harsh coastal environment, including wave action and fluctuating water levels. It should also possess excellent filtration properties to prevent the migration of fine particles while allowing water to pass through. Additionally, the geotextile's permeability and hydraulic conductivity should be considered to ensure proper drainage and avoid the buildup of hydrostatic pressure. The material's resistance to biological degradation and UV radiation is crucial for long-term performance. Lastly, the geotextile should be compatible with the surrounding materials and easy to install and maintain, minimizing disruptions to the coastal ecosystem and reducing overall project costs.

Send your message to us

Geotextile Polypropylène ilament civil woven geotextiles continue fiber from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords