Woven Geotextiles - Polypropylene Nonwoven Geotextile Fabric Reinforcement and Drainage CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

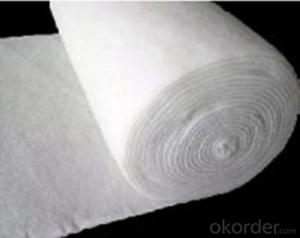

1. short fiber needle punched nonwoven geotextiles (heat set or not) Pet short fiber

2. different color nonwoven geotextile

3. The product has the property of anti-aging, high strength, good flexibility and permeability, filtration, isolation and easy construction

4. It is widely used in areas of the railway, highway, sport venue,dyke,water project construction, tunnel,sea beach,inning,environment protection and so on. It can also used in the reinforcement, separation,filtration,drainage ect.After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

- Q: What type of geotextile is used for soccer field

- Generally with permeable geotextile, 200g300g can be

- Q: Can geotextiles be used in groundwater control?

- Yes, geotextiles can be used in groundwater control. They are commonly employed as part of drainage systems to filter and separate different layers of soil, preventing the clogging and migration of fine particles. Geotextiles can also be used in conjunction with geosynthetics to create impermeable barriers, preventing the seepage or flow of groundwater in certain applications.

- Q: How do geotextiles improve the performance of geocells?

- Geotextiles improve the performance of geocells by providing additional strength, stability, and filtration capabilities. They act as a barrier between the soil and the geocell structure, preventing soil erosion and promoting proper drainage. Geotextiles also enhance load distribution and increase the overall structural integrity of the geocell system, making it more effective in various applications such as soil stabilization, erosion control, and slope protection.

- Q: What is the application of geotextile?

- Water conservancy project dam and slope protection of the filter, channel isolation, anti - seepage. ⒉ road, railway, airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage. ⒊ port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage. ⒋ landfill, thermal power plant ash dam, mine tailings dam isolation, seepage control.

- Q: 300 grams of geotextile how much money a square meter

- See the requirements of the data indicators in general about 2.4 Huazhi geotextile material manufacturers

- Q: How to determine the nominal breaking strength of filament spunbonded nonwoven geotextile

- You can use a dedicated geotextile strong test machine detected.

- Q: What are the factors to consider when selecting geotextiles for coastal protection projects?

- When selecting geotextiles for coastal protection projects, several factors need to be considered. These include the strength and durability of the geotextile, its resistance to UV radiation and chemicals, its ability to filter and drain water, its compatibility with the existing soil and vegetation, its installation and maintenance requirements, and its cost-effectiveness. Additionally, the specific environmental conditions and project goals should also be taken into account.

- Q: What are the physical properties of geotextiles?

- Geotextiles are engineered fabrics with diverse physical properties. They are typically lightweight, flexible, and permeable. Geotextiles can have varying levels of tensile strength, puncture resistance, and abrasion resistance depending on their intended application. They can be woven or non-woven, with the latter being more commonly used in geotechnical applications. Additionally, geotextiles exhibit good resistance to UV degradation, chemicals, and biological degradation.

- Q: Ask geotextile factory in the use of geotextile aperture detector detection method which?

- Hello, geotextile detection method in GB / T and GB / T geotextile aperture in the introduction, you can look at these two standards. The first is geotextile pore size detection wet sieve method, the second is geotextile aperture detection dry sieve method. As the name suggests the first of these two methods is the participation of water, the other is basically the same, are placed in a single layer of geotextile standard small particles, through the vibration to detect the size of the leakage of particles to determine the geotextile pore size size. The difference is that the first standard in the need for continuous water on the particles, so the calculation method are also different. Specific detailed distinctions You can search these two criteria separately.

- Q: What are the maintenance requirements for geotextiles?

- Geotextiles generally require minimal maintenance. However, regular inspection is recommended to identify any signs of damage or deterioration. Additionally, they should be kept clean and free from debris to ensure optimal performance. In case of any tears or holes, prompt repairs should be carried out to prevent further damage. Overall, proper maintenance practices will help extend the lifespan of geotextiles and maintain their effectiveness in various applications.

Send your message to us

Woven Geotextiles - Polypropylene Nonwoven Geotextile Fabric Reinforcement and Drainage CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords