Auto-climbing Formworks with Hydraulic system

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

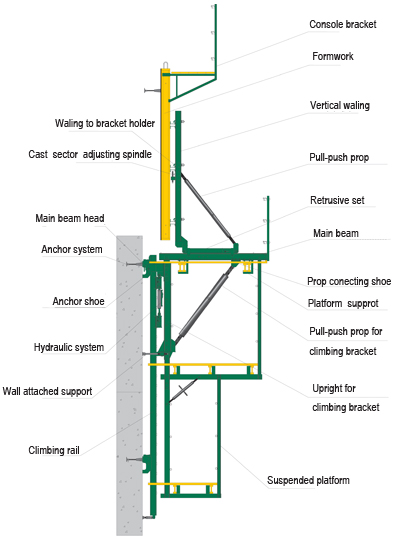

Product Introduction

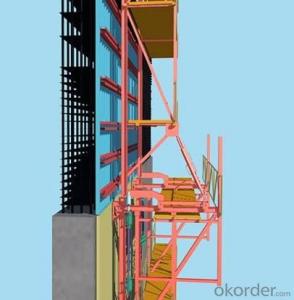

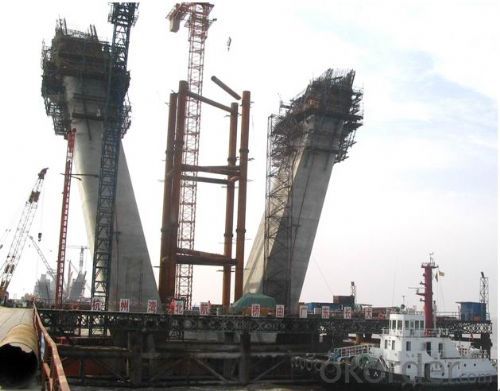

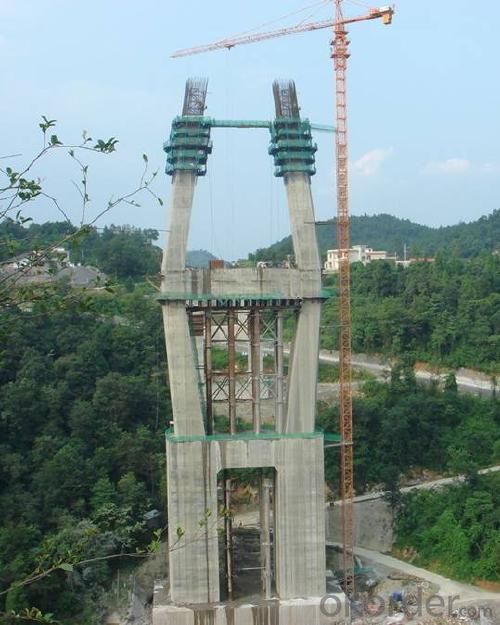

The power of the auto-climbing formwork is the hydraulic system, which includes the oil cylinder and commutators. Through the functioning of hydraulic system, the steel rail and bracket can climb up alternately,The commutators can control the climbing of the climbing rail and the bracket. The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily. Cranes are not needed during the construction. It' s easy to operate, and climbing is fast and safe.

Product Characteristics

1. Perfect load bearing anchor system.

2. Crane-independent

3. One oil cylinder unit can lift 50KN.

4. The QPMX-50 system can climb not only vertically but also slantwise, and the forward or backward inclination can be up to 18 degrees.

5. The system can climb up wholly or separately. The climbing process is steady, synchronous and safe.

6 .The bracket does not come back to the ground until construction work is finished, and spacing for work is reduced while the bumping damage is almost completely prevented, especially for the plywood.

7.The error of structure construction is tiny and easy to correct.

8.The formwork can climb up by itself and cleaning work can be done in situ. The number of crane lifts are greatly reduced.

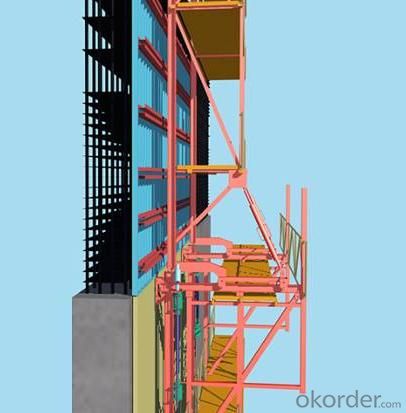

Climbing Process Introduction

1.Set up the formwork by wall-through tie-rods and pull-push props, embed anchors and do the first concrete pouring.

2. Remove the formwork after the first pouring and fix anchor shoes on the finished wall, lift the brackets and formwork to the right position, match the formwork and do the second pouring.

3.Lift formwork and brackets to the higher floor; fix climbing rail and hydraulic system.

4.Match the formwork to the right position and do the third pouring.

5.Strip the formwork and fix anchor shoes on the finished wall, then let the climbing rails climb.

6. Brackets climb up to the right position, then install suspended platform.

7.Match the formwork, do the concrete pouring, and proceed into the standard climbing stage.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Whether or not the double screw nut is used on the important bolt connection, the degree of the fastening, whether the steel bar is pressed according to the rules, and the steel wires are bundled together

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame installation processInstallation of platform --- display base, installation guide, assembling components - horizontal truss beam with the bolt on the guide rail, the main frame vertical rod buckle on the beam - diagonal rod buckle on the vertical rod and beam - wall installation guide device, the frame structure of unloading with elevated body, the erection of scaffolding, the laying of the intermediate layer or temporary scaffolding and temporary building structure frame of pulling and hanging outside the dense mesh safety net - loaded third beams to guide seat -

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- 3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).Clamp and Tube Scaffold2) easy to install and disassemble, set up flexible. Because the length of the steel tube is easy to adjust and the fastener is convenient to connect, the utility model can be used for various buildings and structures with various planes and elevations.3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings. Rental fees do not want the same

Send your message to us

Auto-climbing Formworks with Hydraulic system

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords