Waterproof Slab Formwork System With Adjustable Prop Table Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

suspended slab formwork

slab form work

concrete slab formwork

Waterproof Slab Formwork System With Adjustable Prop Table Formwork

Description:

1. Breif introduction

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution.

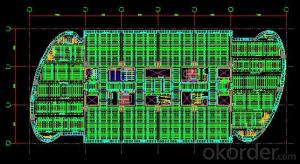

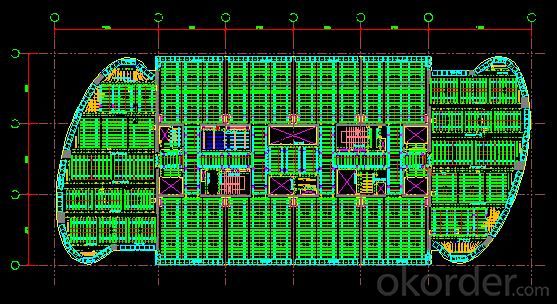

Here, table formwork is designed to suit a particular structure and is customised down to the last detail. If the geometry of the structure requires, for example, a trapezoidal-shaped table for a circular office building, the table system tailored solution is the right choice. Adapting to the shape of the structure means that infill areas are reduced to a minimum. We have to make all the formwork to slab.

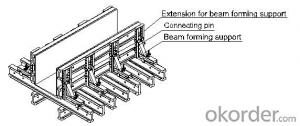

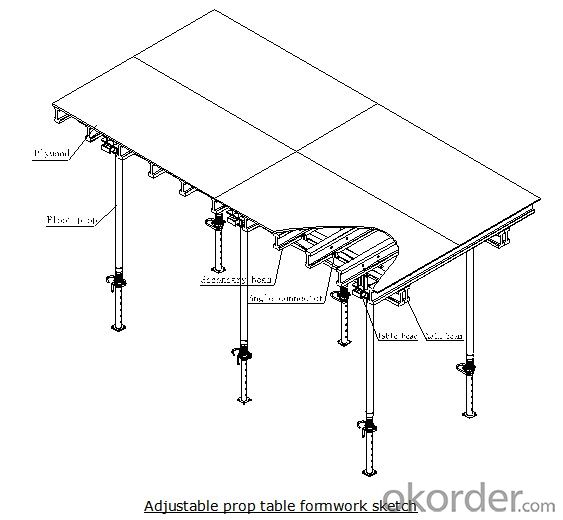

2. Structure of table formwork

3. About the infill areas

For RA-INST system, infill materials are necessary for small space or same special area. They are usually composed of timber beam, prop, head-jack, tripod, and plywood as the below picture shown.

4. Competitive advantage

① Fast construction

The table formwork is pre-assembled; all the structural elements are connected by specific fastenings, so it is easily to move and turnover.

②Easy operation

The formwork is composed of plywood, timber beam, table head and props. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

③Props are adjustable

Table formwork is supported with adjustable props; the props can be pivoted in two directions for meeting the demand of different height.

④Mature system with several kinds of specific tools.

We afford trolley, lifting fork, handrail for TBS-A system, trolley is especially for shifting table formwork from the slab; lifting fork is a lifting tool for lifting the table formwork by crane; The workers will be in a safe site condition by means of handrail.

5. Applications

- Q: How is the hydraulic support moving

- The hydraulic support is connected to the scraper conveyor by pushing the lever and the crosshead: pushing the jack extension, pushing the lever out, pushing the scraper conveyor forward a step, which is called pushing; pushing the jack to take, The board conveyor reacts on the stand, driving the carriage forward by a step, which is called a shift frame.

- Q: Climbing and floor scaffolding advantages and disadvantages

- Floor scaffolding: Advantages: bearing capacity. When the scaffolding geometry and construction in line with the relevant requirements, under normal circumstances, scaffolding single tube column bearing capacity of up to 15kN ~ 35kN (1.5tf ~ 3.5tf, design value).

- Q: What is a climbing frame?

- Climbing frame, also known as attached lift scaffolding, the equipment and equipment is the rapid development of the beginning of this century, a new scaffolding technology, construction technology in China has an important impact. It will be high operations into a low operation, the floating operations into the frame internal operations, with significant low-carbon, high-tech content and more economical, more secure, more convenient and so on.

- Q: Is the scaffolding scaffolding?

- This system makes the scaffolding technology completely changed: one is not to turn the shelf, the second is to remove the scaffolding of the dismantling process (after assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q: Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Crawl profile is also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building. This system makes the scaffolding technology completely changed: one is not to turn the shelves; the second is to remove the scaffolding of the dismantling process (after the assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q: The difference between climbing and sliding mode

- Climbing is a short form of climbing template, also known as jumping abroad. It consists of climbing template, climbing frame (and some climbing no climbing) and climbing equipment composed of three parts, in the construction of shear wall system, the cylinder system and bridge pier and other high-rise structure is an effective tool. Because of the ability to self-climb, so no lifting machinery lifting, which reduces the construction of transport machinery lifting workload. Climbing scaffolds on self-climbing templates eliminates the need for external scaffolding during construction. In summary, climbing the template can reduce the number of lifting machinery, speed up the construction speed, so the economic benefits are better. Slip mode is a slow moving structure of the template, usually a fixed size of the stencil, drawn by the traction device.

Send your message to us

Waterproof Slab Formwork System With Adjustable Prop Table Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords