Auto-climbing Bracket ACB100& ACB50 for Horizontal Platform

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

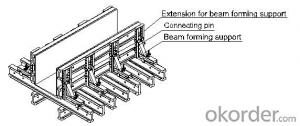

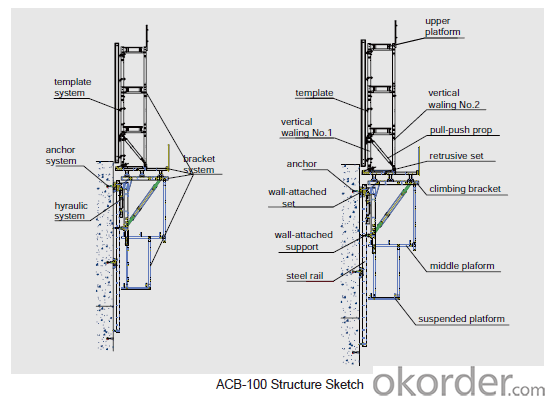

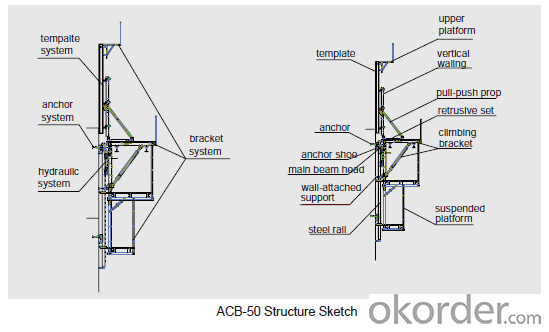

1. Structure of Auto-climbing bracket ACB 100&ACB50

The power of the auto-climbing formwork is the hydraulic system, which includes the oil cylinder and two commutators. The commutators can control the climbing of climbing rail and the bracket. The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily. Cranes are not needed during the construction. It’s easy to operate, highly efficient and safe. It’s the best choice for the construction of high buildings and bridges. There are mainly two types of standard auto-climbing brackets, ACB-50 and ACB-100, the figure means the push power of cylinder with unit of KN.

2. Main Features of Auto-climbing bracket ACB 100&ACB50

- Perfect load bearing anchor system

- Crane-independent

-Reduced cost

-Fast and easy climbing

-Convenient and easy to control

3. Auto-climbing bracket ACB 100&ACB50 images

4. Auto-climbing bracket ACB 100&ACB50 Specifications

5. FAQ of Auto-climbing Bracket ACB 100&ACB50

1) What can we do for you?

.We can ensure the quality of Auto-climbing bracket ACB 100&ACB50 and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q: How is the hydraulic support moving

- Hydraulic support shift method: push the jack extension, push the rod out, push the scraper conveyor forward a step, and then move the jack close, push the lever to take back, scraper conveyor reaction on the bracket, driving the stent forward a step Distance, complete hydraulic support shift frame.

- Q: Climbing and floor scaffolding advantages and disadvantages

- The bolt tightening torque should not be less than 40N · m, and should not be greater than 65N · m; [1] 2) The bar at the node is eccentric, 3) The connection quality of the fastener joints is significantly affected by the quality of the fastener itself and the operation of the workers. (3) The connection quality of the fastener joints is significant.

- Q: What is a climbing frame?

- Taosheng Technology TOSUN as the leading research and development, production, sales, leasing and construction units in China, is committed to providing customers with comprehensive construction safety protection solutions.

- Q: Is the scaffolding scaffolding?

- The difference between scaffolding and scaffolding is that the commonly used scaffolding is always erected from below, and the climbing is followed by the rise of the building, that is, the map made upstairs, and the common thing is that everyone belongs to Scaffolding and the like

- Q: Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Set the mounting platform --- Place the base, install the rails, assemble the horizontal truss parts - connect the beams to the rails with bolts and fasten the main frame to the beams - On the beam - the installation of wall-mounted device, the frame unloading to the guide seat --- with the structure connected to the elevated body, erected scaffolding, laying the middle layer or temporary scaffolding --- and the building structure to do temporary frame Pull the connection, hanging out the top of the safety net --- installed after the third beam, the installation of lifting seat and a layer with a wall guide block --- then the main frame of the main frame, the frame erected to the design height, Laying the top scaffolding plate, foot plate --- laying the bottom of the safety net and scaffolding, the production of flap - the upper frame and the structure of the effective pull-pull (pull-pull spacing of not more than 6m) --- hanging outside the row of dense security To the top of the frame --- the anti-fall boom inserted into the base anti-fall device, install the lifting wire rope --- placed electric control cabinet, distribution cable, install electric hoist, wiring, commissioning electrical system --- preload electric gourd, inspection and acceptance, with removal of the upper frame structure then pull, lift one synchronization --- fully installed, into Upgrade cycle

- Q: The difference between climbing and sliding mode

- Climbing is a short form of climbing template, also known as jumping abroad. It consists of climbing template, climbing frame (and some climbing no climbing) and climbing equipment composed of three parts, in the construction of shear wall system, the cylinder system and bridge pier and other high-rise structure is an effective tool. Because of the ability to self-climb, so no lifting machinery lifting, which reduces the construction of transport machinery lifting workload. Climbing scaffolds on self-climbing templates eliminates the need for external scaffolding during construction. In summary, climbing the template can reduce the number of lifting machinery, speed up the construction speed, so the economic benefits are better. Slip mode is a slow moving structure of the template, usually a fixed size of the stencil, drawn by the traction device.

Send your message to us

Auto-climbing Bracket ACB100& ACB50 for Horizontal Platform

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches