Automatic Climbing Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

self climbing formwork system

self climbing formwork

climbing formwork system

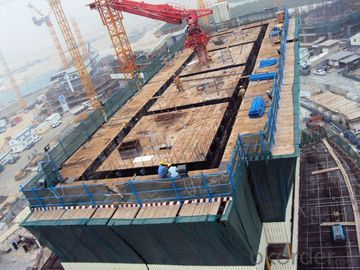

Fast , Efficient Auto-climbing Formwork System ACS50 for High Building

Description:

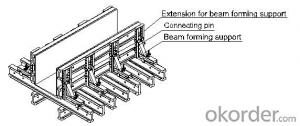

Auto-climbing system ACS50 is composed of formwork system, bracket system, hydraulic system, anchor system. It guarantees simple procedure of assembly and climbing without any lifting machine, so it is the best choice for the high rise building and bridges.

Competitive Advantage:

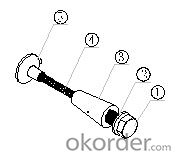

1. Perfect anchor system with high load bearing capacity.

As the picture shown, the anchor system is composed of five parts. The load bearing will firstly be transferred to tensile bolt①, then be transferred to climbing cone③, tensile tie④ and anchor plate⑤, that means the concrete structure will be the final force point. Therefore, the whole ACS system unit is very safe and stable.

2. Crane-independent

Crane-independent forming, striking and climbing speeds up the work procedures on the construction site and also makes them independent of each other. This means the planned sequences can be maintained along with guaranteeing high productivity levels. The crane can therefore be used for other tasks.

3. High bearing capacity and safe

The stable working platforms are able to carry large loads, e.g. the storage of reinforcing steel for the next climbing section. Generously-sized working platforms, the well thought-out design for handling very high wind loads and the patented control function of the climbing mechanism are some of the special details contained within the comprehensive safety concept.

4. Platforms adjusted to suit the angle of inclination

The horizontal working areas thus created provide safe and comfortable conditions for reinforcement work, shuttering and striking, concreting and finishing.

5. Outstanding economical efficiency

The ACF system climbing without any lifting machine and it guarantees the simple operation procedure. Time saving, labor saving, site saving, so economical construction is easily achieved.

- Q: How is the hydraulic support moving

- (1) before the shift frame, open the stent into the liquid valve, clean the frame of floating coal, floating gangue and other debris, or are not allowed to shift frame; also check the roof The situation, and found that the roof broken or pumping the phenomenon of the top of the row, to deal with and then move the shelves, to prevent the process of moving off the roof is too large and cause injury; and to check the front whether there are cables, pipes and other equipment, Clean up and then move the shelves; if you can not clean up the mark after the shelves, to be shut down after a comprehensive treatment. (2) when the shift frame when the first column, so that the top beam from the top plate, stop the column quickly shift frame; for broken roof to allow "rub top shift" or "with pressure shift frame" Should be out of the metal net to avoid tearing the net. (3) after the shift must be arranged neatly formed a straight line; in the roof before and after the top are connected, the appropriate adjustment of the balance jack, so that the bracket to achieve the best support effect.

- Q: Climbing and floor scaffolding advantages and disadvantages

- The bolt tightening torque should not be less than 40N · m, and should not be greater than 65N · m; [1] 2) The bar at the node is eccentric, 3) The connection quality of the fastener joints is significantly affected by the quality of the fastener itself and the operation of the workers. (3) The connection quality of the fastener joints is significant.

- Q: What is a climbing frame?

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building. This system makes the scaffolding technology completely changed: one is not to turn the shelves; the second is to remove the scaffolding of the dismantling process (after the assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q: Is the scaffolding scaffolding?

- This system makes the scaffolding technology completely changed: one is not to turn the shelf, the second is to remove the scaffolding of the dismantling process (after assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q: Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Crawl profile is also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building. This system makes the scaffolding technology completely changed: one is not to turn the shelves; the second is to remove the scaffolding of the dismantling process (after the assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q: The difference between climbing and sliding mode

- Climbing is a short form of climbing template, also known as jumping abroad. It consists of climbing template, climbing frame (and some climbing no climbing) and climbing equipment composed of three parts, in the construction of shear wall system, the cylinder system and bridge pier and other high-rise structure is an effective tool. Because of the ability to self-climb, so no lifting machinery lifting, which reduces the construction of transport machinery lifting workload. Climbing scaffolds on self-climbing templates eliminates the need for external scaffolding during construction. In summary, climbing the template can reduce the number of lifting machinery, speed up the construction speed, so the economic benefits are better. Slip mode is a slow moving structure of the template, usually a fixed size of the stencil, drawn by the traction device.

Send your message to us

Automatic Climbing Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords