25 X 60 mm Black Plastic Modular Formwork Panel for Straight Concrete Wall

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Plastic Modular Formwork Panel:

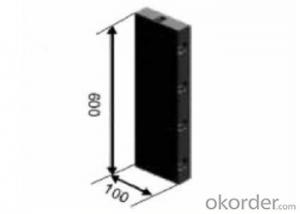

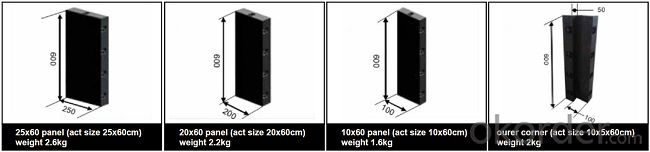

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x1500px, which used for the large area of walls and slabs. There are also small size of panels like 10x60 panel (10x1500px), 20x60 panel (20x1500px),25x60 panel (25x1500px), inner corner (20x20x1500px) and outer corner (10x5x1500px). Due to the variety of panel size, the system can form almost all size walls 120x60 panel (act size 120x1500px) of multiple by 125px.

Using modular formwork, it is possible to pour up to 1000px thick and 3 meters high straight walls one time. Combining with special corners and compensation panels, right angle walls, three way T-walls and four way cross walls can be formed easily. The low weight and modularity of modular formwork makes it ideal for fence walls as it is possible to move large gang forms by hand.

2. Main Features of Plastic Modular Formwork Panel:

a. Easy Set Up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

b. Modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls 120x60 panel (act size 120x60cm) of multiple by 5cm.

c. Strength

The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures. The handles are made by high strength Nylon, each panel

locked by at least 4 handles, which makes the whole system strong enough to pour 40cm walls.

d. Environment Friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the environment.

e. Consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

3. Plastic Modular Formwork Panel Images:

4. Plastic Modular Formwork Panel Specification:

5. FAQ of Plastic Modular Formwork Panel:

1) What promises can be done by us?

If interested in Plastic Modular Formwork, please feel free to write us for any QUOTE.

Please DO check goods when courier knocks your door and contact us asap if any issue.

2) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

Plastic Modular Formwork cost can be refund after order is confirmed.

If the products are not based on the requirements, there will be the relevant compensations made for you.

3) What about the package and shipping time?

Packing:As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Plastic Modular Formwork, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- This is not know your product materials and performance requirements, but the mold, then we generally use 45 steel, if the product is not corrosive strong, then what can be used to compare 50 steel.

- Q: Who used it, how not universal.

- Strong plastic PP plastic template is a joint development of the company's patented product, is the national high-tech industrialization in 2000 to promote the project. The product is based on polypropylene, adding GF fiber, anti-aging additives made of a kind of engineering plastics. Is a plastic generation of steel (bamboo, wood) a new generation of building templates.

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Aluminum alloy template is the best architectural template, the advantages of a high number of turnaround, the theory is 300 times, but the actual use of 60 will have a small part of the deformation, a comprehensive calculation of 150 no problem, the second is quick, every worker day Can be assembled 20 square meters or more, three is light weight, manual transmission is very convenient, do not rely on tower crane, four is the quality assurance, the basic can meet the specifications, five is conducive to civilized construction, will not produce garbage and noise, No wood. Disadvantages of a high cost, and second, only in the standard layer to use to play advantage

- Q: Europe and the United States national construction template is made of plastic or wood

- Part of the place with stones, as the case may be, but certainly yes, Europe and the United States have anti-seismic buildings

- Q: Plastic mold dynamic template, the size of the template

- A lot of it? What are you talking about? Plastic mold points a lot of tonnage, there are 80T, 120T, 240T, 1000T, 1250T

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- Stupid way, with a little hammer little bit of the beat, out a little less a little bit.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- This does exist. The reason is that the plastic building template in the cut and fixed convenience, significantly weaker than the wooden building template, and in the demolition process, due to the brittleness of plastic, but also easy to break, and the cost of plastic template is too high, so the site Are generally willing to use wooden building templates. If you want to improve the number of wood construction template use, that is, cost, it is recommended that you choose building templates within 30 strong business

- Q: Plastic building template where there is an urgent need to solve

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- This size is an international common size. Because more foreign use of foot units, 1 foot = 30.5cm, 1830 × 915 is usually said that the three or six feet board.

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Plastic building template to be extended when the expansion joints: As the plastic building template than the steel mold, wood mold thermal expansion coefficient larger, morning and evening laying plastic template must be reserved for about 2 mm expansion joints (according to the size of the day the temperature difference ), No need to reserve the expansion of the slit at noon. The length of the nail is generally 1.5 inches to 2 inches is appropriate, not too long or too short.

Send your message to us

25 X 60 mm Black Plastic Modular Formwork Panel for Straight Concrete Wall

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords