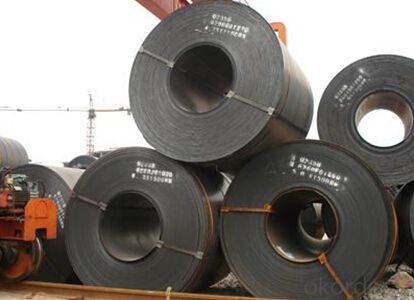

HR Steel Coil SS400 A36 Q235 Q345 Q195 Hot Rolled Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

HR Steel Coil SS400 A36 Q235 Q345 Q195 Hot Rolled Steel Coil

Quick Details

Name | Hot Rolled Steel Coil |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

Hot Rolled Steel Coil Specification : Width(mm)*Thickness(mm) | ||

145*2.5 | 255*2.2 | 315*2.75 |

156*1.3 | 255*2.3 | 355*1.5 |

156*1.5 | 255*2.5 | 335*1.7 |

156*1.8 | 272*1.5 | 335*1.8 |

156*2.0 | 272*1.7 | 335*2.0 |

183*1.2 | 272*1.8 | 335*2.2 |

183*1.3 | 272*2.0 | 335*2.3 |

183*1.5 | 272*2.2 | 335*2.5 |

183*2.0 | 272*2.3 | 355*1.5 |

196*1.3 | 272*2.5 | 355*1.7 |

196*1.5 | 295*1.5 | 355*1.8 |

196*1.7 | 295*1.7 | 355*2.0 |

196*1.8 | 295*1.8 | 355*2.2 |

196*2.0 | 295*2.0 | 355*2.3 |

196*2.2 | 295*2.2 | 355*2.5 |

196*2.3 | 295*2.3 | 385*2.5 |

196*2.5 | 295*2.5 | 385*2.75 |

232*1.0 | 295*2.75 | 395*2.5 |

232*1.3 | 305*1.5 | 395*2.75 |

232*1.5 | 305*1.7 | 395*3.5 |

232*1.7 | 305*1.8 | 395*3.75 |

232*1.8 | 305*2.0 | 395*4.0 |

232*2.0 | 305*2.2 | 406*2.0 |

232*2.2 | 305*2.3 | 406*2.3 |

232*2.3 | 305*2.5 | 413*2.0 |

232*2.5 | 315*1.5 | 434*3.0 |

255*1.0 | 315*1.7 | 485*3.0 |

255*1.3 | 315*1.8 | 512*3.75 |

255*1.5 | 315*2.0 | 515*2.5 |

255*1.7 | 315*2.2 | 515*4.2 |

255*1.8 | 315*2.3 | 515*3.0 |

255*2.0 | 315*2.5 | 515*4.75 |

Company Information

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. |

l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours | |

Advantages | Industry experience over 20 years. |

Shipment of goods -More than 70 countries worldwide. | |

The most convenient transport and prompt delivery. | |

Competitive price with best service. | |

High technical production line with top quality products. | |

High reputation based on best quality products. |

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: Can special steel be used in the production of knives and blades?

- Yes, special steel can indeed be used in the production of knives and blades. Special steels, such as stainless steel or high-carbon steel, possess properties like corrosion resistance, hardness, and toughness that make them ideal for manufacturing durable and high-performance knives and blades. These steels are often chosen for their ability to retain sharpness, withstand heavy use, and resist rust, ensuring the longevity and reliability of the knives and blades.

- Q: What are the properties of precipitation-hardening steel?

- Precipitation-hardening steel, also known as PH steel, possesses several unique properties. Firstly, it has excellent strength and toughness, making it suitable for various demanding applications. This type of steel can be heat treated to achieve higher strength levels, allowing it to withstand heavy loads and resist deformation. Additionally, precipitation-hardening steel offers good corrosion resistance, making it ideal for use in harsh environments. It also exhibits good machinability, enabling ease of fabrication. These properties make precipitation-hardening steel a versatile material widely used in industries such as aerospace, automotive, and medical.

- Q: What are the requirements for special steel used in construction equipment manufacturing?

- The requirements for special steel used in construction equipment manufacturing are stringent and specific. Here are some key requirements: 1. High strength: Special steel used in construction equipment manufacturing should possess high tensile strength and yield strength to withstand heavy loads and stresses. This ensures the equipment's durability and longevity. 2. Toughness: The steel should have excellent toughness to resist fracture and deformation under impact or dynamic loading conditions. This is crucial for construction equipment operating in challenging environments. 3. Wear resistance: Construction equipment is subjected to abrasive forces, such as digging, scraping, and crushing. Therefore, the special steel should exhibit high wear resistance to prevent premature wear and failure. 4. Corrosion resistance: Construction equipment often operates in harsh environments, such as construction sites, mines, and marine applications. The steel should have good corrosion resistance to prevent rusting and corrosion, which can weaken the equipment's structural integrity. 5. Weldability: Construction equipment manufacturing involves various fabrication processes, including welding. The special steel should have good weldability to ensure proper joining and structural integrity without compromising strength. 6. Heat resistance: In certain construction applications, equipment may be subjected to high temperatures or thermal cycling. Special steel should have good heat resistance to maintain its mechanical properties and structural stability under these conditions. 7. Formability: Construction equipment often consists of complex shapes and structures. The steel should have good formability to allow for easy shaping and fabrication into the desired components without compromising its mechanical properties. 8. Cost-effectiveness: While meeting the above requirements, special steel used in construction equipment manufacturing should also be cost-effective. This means balancing the desired properties with the economic feasibility of production and procurement. Meeting these requirements ensures that the special steel used in construction equipment manufacturing can withstand the demanding conditions, provide long-term durability, and ensure the safety and efficiency of the equipment. Additionally, compliance with industry standards and regulations is essential to guarantee the quality and reliability of the steel used in construction equipment manufacturing.

- Q: How does special steel perform in high-impact applications?

- Special steel has been specifically designed to excel in high-impact applications, showcasing unique properties that allow it to withstand extreme forces and impacts without deforming or breaking. Notably, one of the standout features of special steel is its exceptional strength and hardness, enabling it to effectively absorb and distribute impact forces. Consequently, this prevents the material from shattering or deforming under heavy loads, rendering it highly suitable for applications such as construction machinery, automotive parts, and industrial equipment. Furthermore, special steel exhibits outstanding toughness, enabling it to resist cracking or fracturing when subjected to sudden and intense impacts. This quality proves crucial in high-impact applications where the material must endure repeated forces without failure. The toughness of special steel is achieved through meticulous alloying and heat treatment processes, which significantly enhance its energy absorption capacity and fracture resistance. Moreover, special steel often possesses superior properties such as wear resistance, corrosion resistance, and heat resistance, all of which contribute to its overall performance in high-impact applications. These heightened characteristics allow the material to maintain its integrity and functionality even when exposed to harsh environments or extreme temperatures. In conclusion, special steel showcases exceptional performance in high-impact applications as a result of its remarkable strength, toughness, wear resistance, corrosion resistance, and heat resistance. These properties establish it as a reliable and durable choice for industries requiring materials capable of withstanding intense forces and impacts.

- Q: What are the different surface finishing techniques for special steel parts?

- There are several surface finishing techniques for special steel parts, including electroplating, powder coating, painting, polishing, and passivation. Each technique offers unique benefits and can be chosen based on the desired appearance, corrosion resistance, durability, and functionality of the steel parts.

- Q: How does special steel contribute to the manufacturing of industrial machinery?

- Special steel contributes to the manufacturing of industrial machinery by providing enhanced strength, durability, and resistance to wear and corrosion. It allows for the production of components that can withstand high temperatures, heavy loads, and harsh operating conditions. The unique properties of special steel enable the creation of precision parts, gears, bearings, and tools that are crucial for the efficient and reliable functioning of industrial machinery.

- Q: What are the main characteristics of structural steel forgings?

- The main characteristics of structural steel forgings include high strength, excellent toughness, and superior fatigue resistance. They are also known for their ability to withstand extreme temperatures and harsh environments. Moreover, structural steel forgings exhibit good weldability and machinability, making them suitable for various engineering applications.

- Q: Does special steel have any magnetic properties?

- Depending on its composition and treatment, special steel can indeed possess magnetic properties. The primary constituent of steel is iron, which is inherently ferromagnetic and capable of being magnetized. However, the magnetic characteristics of steel can be influenced by the presence of other elements such as nickel, cobalt, and various alloys. For example, stainless steel, which contains chromium and nickel, is typically either non-magnetic or only weakly magnetic. Conversely, materials like tool steel or high-speed steel may exhibit more pronounced magnetic properties due to their specific composition and heat treatment. Consequently, it is crucial to take into account the precise type of special steel and its alloying elements when assessing its magnetic behavior.

- Q: How does special steel perform in high-temperature oxidation conditions?

- Special steel, also known as heat-resistant or high-temperature steel, is specifically designed to perform exceptionally well in high-temperature oxidation conditions. Oxidation, a chemical reaction between the metal and oxygen at elevated temperatures, can lead to the formation of metal oxides and ultimately result in degradation or failure of the material. However, special steel is formulated with alloying elements that provide superior resistance to oxidation. These alloying elements, such as chromium, aluminum, and silicon, form a protective layer of oxides on the surface of the steel when exposed to high temperatures. This layer acts as a barrier, preventing further oxidation of the underlying metal. Additionally, the alloying elements can enhance the formation of stable and adherent oxide scales, which further improve the steel's resistance to oxidation. Special steel's excellent performance in high-temperature oxidation conditions can be attributed to several factors. Firstly, the alloying elements in the steel composition ensure the formation of a protective oxide layer, which acts as a shield against further oxidation. Secondly, the steel's microstructure is specifically designed to maintain stability and retain its mechanical properties even at elevated temperatures. Furthermore, special steel undergoes rigorous heat treatment processes to enhance its high-temperature oxidation resistance. Heat treatment methods such as annealing, quenching, and tempering optimize the steel's microstructure and eliminate impurities, ensuring its optimal performance in extreme conditions. Overall, special steel demonstrates exceptional resistance to high-temperature oxidation conditions due to its carefully selected alloying elements, tailored microstructure, and optimized heat treatment processes. It provides a reliable and durable solution for various industries that require materials to withstand severe oxidation environments, ensuring optimal performance and longevity in these challenging conditions.

- Q: What are the properties of heat-resistant steel?

- Heat-resistant steel has several important properties. First, it has a high melting point, allowing it to withstand extremely high temperatures without melting or losing its structural integrity. Additionally, it exhibits excellent strength and toughness, ensuring that it can withstand mechanical stresses even at elevated temperatures. Heat-resistant steel also possesses good oxidation resistance, preventing it from reacting with oxygen and forming destructive oxides when exposed to high temperatures. Furthermore, it has low thermal expansion, which means it maintains its shape and dimensions even under extreme thermal conditions. Overall, these properties make heat-resistant steel highly suitable for applications involving high temperatures, such as in furnaces, boilers, and aerospace components.

Send your message to us

HR Steel Coil SS400 A36 Q235 Q345 Q195 Hot Rolled Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords