Hot Rolled Steel Coils, A36,SS400,Q235B,SPHC

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

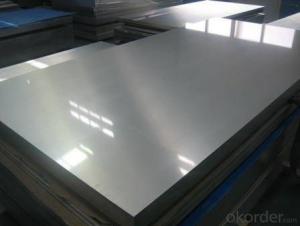

Product: | Hot Rolled Steel Coils/Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Technique: | hot rolled |

Thickness | 1.2mm to 200mm |

Tolerance of thickness: | :+/-0.03mm |

Width: | 750mm-2000mm |

Tolerance of width: | :+/-5.00mm (aiming to +/-2.00mm) |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 508mm-610mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | Black, Chromate, fingerprint resistant treatment, slight oiled or non-oiled, dry |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

components | C

| Si

| Mn

| P ≤ | S ≤ | N | TAl | V | Nb | Ni |

0.06-012 | 0.15-0.30 | 0.25-0.50 | 0.030 | 0.030 | ||||||

Use | Various types of steel components for riveting, bolting, welding. | |||||||||

size | 3000-118800mm*1500-4000mm*6-700mm | |||||||||

Thickness | 6-700mm | |||||||||

Standard | DIN17100 | |||||||||

Material | ST37-2 | |||||||||

Packing | According to the demand of the customer | |||||||||

Surface treatment | Hot-rolled | |||||||||

- Q: What are the typical tolerances for steel coils?

- The typical tolerances for steel coils can vary depending on the specific requirements and standards of the industry. However, common tolerances for steel coils typically range between +/- 0.005 to 0.020 inches in terms of thickness, width, and length. These tolerances ensure that the steel coils meet the desired specifications and can be used effectively in various applications.

- Q: What are the different types of coil edge trimming machines?

- In the market, one can find a variety of coil edge trimming machines. These machines are specifically designed for the purpose of trimming the edges of coils or rolls made from different materials like metal, paper, plastic, or fabric. Each machine type possesses unique features and capabilities to cater to specific trimming needs. 1. Manual Edge Trimmers: These machines require manual operation where an operator feeds the coil and trims the edges using a cutting tool or blade. Manual edge trimmers are suitable for trimming applications with low volumes and rely on the skill and precision of the operator. 2. Semi-automatic Edge Trimmers: These machines offer automated feeding mechanisms to assist in the coil feeding process. However, the operator still performs the trimming manually using a cutting tool. The feeding mechanism reduces manual effort and increases productivity. 3. Automatic Edge Trimmers: These fully automated machines require minimal operator intervention. Equipped with advanced sensors and controls, they ensure precise and consistent trimming of coil edges. Automatic edge trimmers can handle high volumes of coils and are often integrated into production lines for continuous trimming operations. 4. Rotary Blade Edge Trimmers: These machines utilize high-speed rotating blades to trim coil edges with precision. Commonly used for plastic or fabric coils, they provide clean and smooth cuts. 5. Guillotine Edge Trimmers: These machines employ a guillotine-like cutting mechanism to trim coil edges. The cutting blade moves vertically, resulting in straight and accurate cuts. Guillotine edge trimmers are suitable for trimming metal or paper coils. 6. Laser Edge Trimmers: These machines adopt laser technology to trim coil edges. The laser beam ensures clean and precise cuts, making them ideal for delicate or high-value materials. The choice of the appropriate coil edge trimming machine depends on the specific requirements of the application. Factors such as material type, coil dimensions, trimming precision, and production volume should be taken into consideration. Each machine type has its own advantages and limitations.

- Q: What are the safety precautions for handling steel coils?

- Some safety precautions for handling steel coils include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. It is important to ensure proper lifting techniques are used, utilizing equipment like forklifts or overhead cranes when necessary. Coils should be stored and stacked securely to prevent them from falling or rolling. Regular inspections of coils and equipment should be conducted to identify any potential hazards or damages. Additionally, workers should be trained on safe handling procedures and be aware of the weight and dimensions of the coils they are handling.

- Q: How are steel coils used in the production of automobile frames?

- Steel coils are used in the production of automobile frames as they are unrolled and shaped into the desired form to create the structural framework that provides strength and rigidity to the vehicle.

- Q: What is the most common bullet resistant steel that is used, can certain bullets just not be stopped, also what type of glass is bullet resistant or is that special made.

- The trauma plates in most vests are made from titanium steel. But the real issue is how thick a plate of a particular material must be to soak up the kinetic energy of a particular bullet. Certain bullets are a lot easier to stop than others. But, again, it's all about the bullet mass and velocity. Bulletproof glass is usually several layers of glass bonded together with a clear plastic film and it's generally special made. Doug

- Q: This needs to be in a percentage by mass. Could you please also reference where this info has come from. Thanks.

- Steel is produced in different grades,depending on the amount of iron, and chromium, and any other alloying metal that might be in that particular grade. Any good welders hand book would be a good source of information on steel and its properties.

- Q: Can steel coils be coated with aluminum?

- Yes, steel coils can be coated with aluminum through a process called coil coating.

- Q: i want to know what is light gauge steel and the diffrences between light gauge steel and steel for roof truss.

- as a welder i can answere this. wel i think i can after 2 years of classes. so...light guage steel usually referes to the THICKNESS of the metal. also known as SHEET METAL. the only diffrences between light guage and roof truss is that a truss will be thicker metal ex- an i-beam for a structure is usually 1/2inch or 3/8 for smaller buildings. also there is no such thing as light weight steel. steel is steel the only thing that determins its weight is its size/thickness aluminum is a whole nother ballgame. ever see a pound of aluminum vs. a pound of steel? aluminum can be 1/2 or less the weight of steel. but its tensile strength suffers EX. say steel will snap at 70,000 pounds, aluminum will snap at 40,000 pounds, if it even snaps that is! it just tends to bend like rubber. aluminum is handy for many things because it will not rust.

- Q: How are steel coils inspected for camber?

- Steel coils are inspected for camber by using a straight edge or a camber gauge, which is placed on top of the coil to measure any deviation from straightness. The operator checks the distance between the straight edge and the coil at various points along its length to determine the amount of camber present.

- Q: How are steel coils tested for strength?

- Steel coils are tested for strength through a process called tensile testing. In this test, a small sample of the steel coil is pulled until it breaks, allowing engineers to measure the maximum force the coil can withstand before failing. This helps determine the overall strength and quality of the steel coil.

Send your message to us

Hot Rolled Steel Coils, A36,SS400,Q235B,SPHC

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords