Steel Rolled Coil SS400 Q195 Hot Rolled Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Structure of Steel Rolled Coil SS400 Q195 Hot Rolled Steel Coil Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Steel Rolled Coil SS400 Q195 Hot Rolled Steel Coil:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

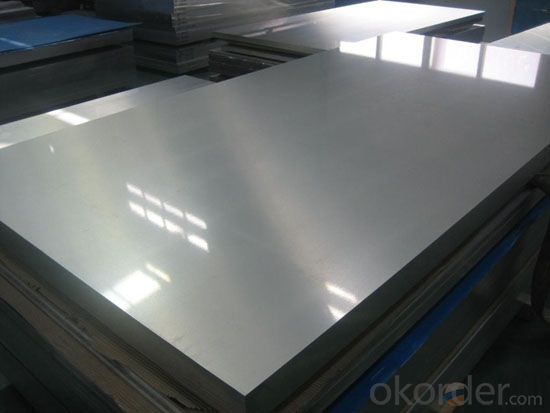

General Information of Cold Rolled Steel Sheet

The raw material of cold rolled steel sheet is high quality hot rolled product, and after pickling, continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as processing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

Specifications of Cold Rolled Steel Sheet

1) Grade: SPCC, SPCD, SPCE, DC01-06, St12, Super deep drawing

2) Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

3) Thickness: 0.20mm - 3.0mm

4) Width: 600/1000/1250/1500 (mm) or per customer's request

Package of Cold Rolled Steel Sheet

Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

Applications of Cold Rolled Steel Sheet

1) For the further producing of hot dip galvanized steel products

2) Cold rolled Steel: Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Aluminum is a versatile material that can be easily manipulated into different shapes and forms, making it ideal for various architectural applications. It is commonly used for exterior cladding, roofing, window frames, and facades, providing a sleek and modern aesthetic to buildings. Aluminum sheets can also be used for decorative purposes, such as wall panels, art installations, signage, and furniture. The lightweight and durable nature of aluminum make it a popular choice for architects and designers looking to create visually appealing and functional structures. Additionally, aluminum is resistant to corrosion, making it suitable for both indoor and outdoor applications.

- Q: Can 101 aluminum sheets be bent without cracking or breaking?

- 101 aluminum sheets can be bent without cracking or breaking if proper bending techniques are employed. Aluminum 101 is a relatively soft and malleable alloy, making it suitable for bending. However, it is important to consider the thickness of the sheets and the radius of the bend. Thicker sheets may require more force to bend, increasing the risk of cracking. Additionally, sharp bends with a small radius may also cause cracking. To prevent this, it is recommended to use a bending machine or tool specifically designed for aluminum bending. This will ensure even pressure distribution and minimize the risk of cracking or breaking. Overall, while 101 aluminum sheets can generally be bent without issue, it is crucial to apply appropriate techniques and consider the specific parameters to avoid any potential damage.

- Q: What is the atomic number of aluminum?

- The atomic number of aluminum is 13.

- Q: Are aluminum sheets suitable for food packaging?

- Yes, aluminum sheets are suitable for food packaging. Aluminum is a lightweight, non-toxic, and corrosion-resistant material that provides an effective barrier against moisture, oxygen, and light. It helps preserve the quality, taste, and freshness of food products, making it a popular choice for packaging perishable items. Additionally, aluminum is recyclable, making it an environmentally-friendly option for food packaging.

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: Are 101 aluminum sheets suitable for automotive body panels?

- Certainly, automotive body panels can be made suitable by utilizing 101 aluminum sheets. This particular alloy, known as 101 aluminum, possesses remarkable attributes such as high strength, good formability, and corrosion resistance, rendering it an exceptional option for automotive purposes. Moreover, its lightweight composition aids in enhancing fuel efficiency and the overall performance of vehicles. Furthermore, 101 aluminum's impressive dent resistance ensures that body panels can endure impacts while preserving their structural integrity. All in all, opting for 101 aluminum sheets to create automotive body panels proves to be a pragmatic and efficient decision.

- Q: Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum, making it thicker and more durable. This process can be customized to achieve various finishes such as clear, colored, or even textured surfaces. The type of finish depends on factors like the alloy composition, anodizing method, and the desired appearance. Anodized aluminum sheets are widely used in various industries including architecture, automotive, and electronics due to their corrosion resistance, aesthetic appeal, and ability to retain color over time.

- Q: Are 101 aluminum sheets resistant to UV radiation?

- Yes, 101 aluminum sheets are generally resistant to UV radiation.

- Q: How do aluminum sheets compare to copper sheets in terms of conductivity?

- When it comes to conductivity, aluminum sheets and copper sheets have their differences. Copper is known for its exceptional ability to conduct electricity and is considered one of the most conductive metals available. Its high electrical conductivity allows electricity to flow through it with minimal resistance. On the other hand, aluminum, while still a good conductor of electricity, is not as conductive as copper. In fact, aluminum has about 61% of the conductivity that copper possesses. As a result, if high conductivity is a top priority, copper sheets would be the preferred option. However, if cost-effectiveness and lightweight properties are more important, aluminum sheets can still offer adequate conductivity for many applications. Ultimately, the decision between aluminum and copper sheets relies on the specific project requirements and the balance between conductivity, cost, and other factors.

- Q: Can aluminum sheets be waterjet cut?

- Indeed, it is possible to employ waterjet cutting for aluminum sheets. By utilizing a combination of high-pressure water and an abrasive substance, waterjet cutting proves to be an adaptable approach in severing a range of materials, including aluminum and other metals. The efficacy of this technique in cutting aluminum stems from its ability to avoid heat generation, thereby preventing potential distortion or harm to the metal. Moreover, it ensures exceptional precision and accuracy, facilitating the effortless cutting of intricate shapes and designs. Consequently, waterjet cutting has become a prevalent practice in industries necessitating immaculate and precise cuts in aluminum sheets, such as aerospace, automotive, and manufacturing.

Send your message to us

Steel Rolled Coil SS400 Q195 Hot Rolled Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords