Hot Selling H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

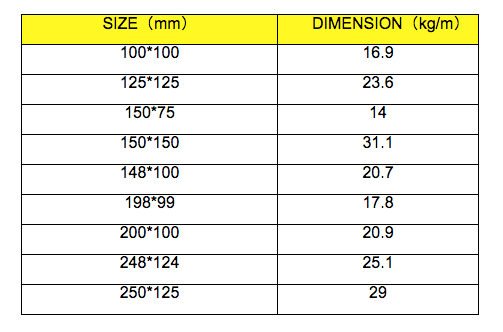

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: What are the considerations when designing for natural disaster planning in Steel H-Beams?

- When designing for natural disaster planning in Steel H-Beams, there are several considerations to keep in mind. Firstly, it is crucial to understand the specific requirements and regulations set by local building codes and standards for structural resilience against natural disasters such as earthquakes, hurricanes, or floods. These codes often include guidelines for material strength, connections, and overall structural stability. Additionally, the design should account for the potential impact of extreme environmental conditions on the steel beams, such as high winds, heavy rain, or seismic forces. Engineers should consider factors like load-bearing capacity, deflection, and buckling resistance to ensure the beams can withstand the expected forces and remain intact during a natural disaster. Furthermore, proper connections and detailing of the steel H-beams are vital to ensure the overall structural integrity. The design should incorporate appropriate joint connections, such as welding or bolted connections, to ensure that the beams can effectively transfer forces and resist any sudden movements or displacements caused by the disaster. Lastly, regular inspections, maintenance, and repairs should be included in the design considerations. These measures help to ensure the ongoing safety and reliability of the steel H-beams, as any damage or deterioration can compromise their performance during future natural disasters. In summary, when designing for natural disaster planning in Steel H-Beams, it is essential to adhere to local building codes, consider the impact of extreme environmental conditions, incorporate proper connections and detailing, and prioritize ongoing maintenance and inspections.

- Q: How do Steel H-Beams contribute to the overall natural ventilation of a structure?

- Steel H-Beams do not directly contribute to the natural ventilation of a structure. Natural ventilation refers to the process of using natural forces, such as wind and temperature differences, to circulate air within a building. However, Steel H-Beams can indirectly impact the natural ventilation of a structure by providing the necessary structural support for windows and openings. H-Beams are commonly used in construction to support the weight of the building and distribute it evenly. They are often used in the framework of a structure, allowing for the creation of large openings for windows or doors. These openings play a crucial role in natural ventilation as they allow fresh air to enter the building while allowing stale air to exit. By incorporating Steel H-Beams into the design of a structure, architects and engineers can create larger openings for windows and doors. This allows for increased airflow, enabling the natural ventilation process to be more effective. The H-Beams provide the necessary strength and stability to support these larger openings, ensuring the overall structural integrity of the building. In addition to supporting openings, Steel H-Beams can also be used to create roof structures that facilitate natural ventilation. By creating a pitched or sloped roof design, H-Beams can provide the necessary framework for the installation of vents or skylights. These features allow hot air to rise and escape, drawing in cooler air from lower levels and promoting natural airflow within the building. While Steel H-Beams themselves do not directly contribute to natural ventilation, their presence in the construction of a structure enables the incorporation of windows, doors, and other ventilation features. By providing the necessary structural support, Steel H-Beams play a vital role in enhancing the overall natural ventilation of a building.

- Q: How do steel H-beams provide structural support?

- Steel H-beams provide structural support by distributing the load evenly across their horizontal flanges and transferring it to the vertical web, which in turn transfers the load to the supporting columns or walls. This design allows for increased strength and stability, making H-beams an ideal choice for supporting heavy loads in various construction applications.

- Q: Can steel H-beams be used in industrial warehouses?

- Indeed, industrial warehouses can utilize steel H-beams. In the realm of construction and industrial applications, warehouses commonly employ steel H-beams. They possess robustness, longevity, and offer exceptional structural reinforcement. The distinctive H-shape of these beams amplifies their load-bearing capacity, rendering them optimal for accommodating hefty loads and expansive spans. Furthermore, steel H-beams can be effortlessly fashioned, installed, and modified to meet the precise specifications of the warehouse structure. These beams present a cost-efficient and effective resolution for the construction of industrial warehouses.

- Q: How do steel H-beams resist lateral forces?

- Steel H-beams are designed to resist lateral forces through their structural shape and material properties. The H-beam shape itself provides excellent resistance against lateral forces by distributing the load across the entire length of the beam. The horizontal flanges of the H-beam are designed to withstand bending and torsion, while the vertical web connects and stabilizes the flanges, preventing them from buckling under lateral loads. Additionally, the material properties of steel contribute to the H-beam's resistance against lateral forces. Steel is known for its high strength and stiffness, making it an ideal material for structural applications. The strength of steel allows H-beams to withstand large forces without deformation or failure. The stiffness of steel helps to maintain the shape of the beam and prevent excessive deflection under lateral loads. To further enhance the resistance against lateral forces, H-beams can be reinforced with additional bracing or connections. These reinforcements help to distribute the lateral loads more evenly and increase the overall stability of the structure. In summary, steel H-beams resist lateral forces through their structural shape, material properties, and potential reinforcements. The H-beam shape distributes the load, while the strength and stiffness of steel provide the necessary resistance against lateral forces.

- Q: Can steel H-beams be used for supporting water treatment plants?

- Yes, steel H-beams can be used for supporting water treatment plants. Steel H-beams are commonly used in construction due to their strength and durability. They provide excellent load-bearing capacity and can withstand the weight and pressure exerted by the various components of a water treatment plant, such as tanks, pipes, and equipment. Additionally, steel H-beams can be easily fabricated and customized to meet the specific requirements of the water treatment plant, ensuring a stable and reliable support structure.

- Q: Are Steel H-Beams suitable for theater or performing arts center construction?

- Yes, Steel H-Beams are suitable for theater or performing arts center construction. They provide excellent structural support, allowing for large open spaces and versatile design possibilities. Their strength and durability make them ideal for withstanding heavy loads and providing a stable framework for the building. Additionally, steel H-beams can be easily fabricated and customized to meet the specific needs of the theater or performing arts center.

- Q: Can steel H-beams be customized to specific lengths?

- Yes, steel H-beams can be customized to specific lengths. The length of steel H-beams can be altered during the manufacturing process to meet the specific requirements of construction projects.

- Q: Can steel H-beams be used in the construction of warehouses or storage facilities?

- Absolutely, warehouses or storage facilities can definitely utilize steel H-beams for construction purposes. The construction industry widely embraces steel H-beams due to their exceptional strength, durability, and versatility. They offer superb structural support and possess the capability to endure heavy loads, thus rendering them suitable for expansive industrial structures like warehouses or storage facilities. H-beams are frequently employed as columns or beams in the construction of the framework, thereby providing stability and support to the overall structure. Moreover, steel H-beams boast numerous advantages, including effortless installation, fire resistance, and corrosion resistance, which make them an ideal choice for constructing enduring and secure warehouses or storage facilities.

- Q: Can steel H-beams be used in outdoor applications?

- Certainly! Outdoor applications can indeed make use of steel H-beams. Renowned for their robustness, endurance, and ability to withstand environmental conditions, steel H-beams prove to be an apt choice for diverse outdoor projects. The construction industry frequently employs these beams for the construction of bridges, retaining walls, and building structures. Moreover, they exhibit remarkable resistance to moisture, extreme temperatures, and other elements, ensuring minimal deterioration or compromise in structural integrity. Consequently, when durability and longevity are paramount, steel H-beams emerge as a dependable option for outdoor applications.

Send your message to us

Hot Selling H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords