Hot Rolled Structural Steel H-beam JIS Standard all Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Structural Steel H-beam JIS Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Structural Steel H-beam JIS Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

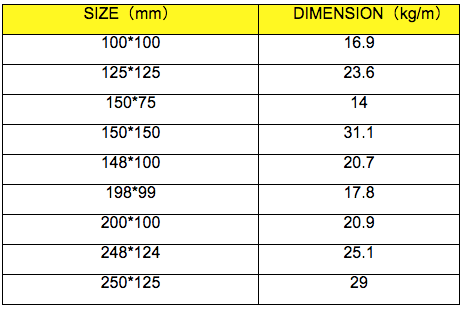

Specifications of Hot Rolled Structural Steel H Beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Structural Steel H Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: How do steel H-beams contribute to the overall sustainability of a structure?

- Steel H-beams contribute to the overall sustainability of a structure in several ways. Firstly, steel is a highly durable material that can withstand extreme weather conditions, seismic activities, and fire, which ensures the longevity and safety of the structure. This durability reduces the need for frequent repairs or replacements, minimizing the consumption of resources and waste generation. Additionally, steel H-beams are lightweight compared to other building materials like concrete or wood, which reduces the overall weight of the structure. This lightweight characteristic allows for more efficient transportation and construction processes, leading to reduced energy consumption and carbon emissions during construction. Moreover, steel H-beams are highly recyclable, making them a sustainable choice. At the end of a building's life cycle, these beams can be easily dismantled and recycled into new steel products without losing their inherent properties. Recycling steel reduces the demand for virgin materials, conserves energy, and reduces greenhouse gas emissions associated with the production of new steel. Furthermore, steel H-beams offer design flexibility, allowing architects and engineers to create innovative and efficient structures. Their versatility enables the optimization of material usage, reducing waste and maximizing the use of resources. This adaptability also facilitates the future adaptability of the structure, allowing for modifications or expansions without extensive demolition or reconstruction. Lastly, steel H-beams have a high strength-to-weight ratio, meaning they can support larger loads with less material. This efficiency in material usage reduces the overall environmental impact of the structure, as less steel is required to achieve the same structural integrity. Therefore, the use of steel H-beams in construction contributes to the conservation of resources and minimizes the carbon footprint of the building. In conclusion, steel H-beams contribute to the overall sustainability of a structure through their durability, lightweight nature, recyclability, design flexibility, and efficient material usage. By choosing steel H-beams, we can create structures that are not only safe and long-lasting but also environmentally friendly, conserving resources and reducing the carbon footprint of the construction industry.

- Q: What is the maximum load capacity of steel H-beams?

- The maximum load capacity of steel H-beams can be subject to variations based on several factors, including the beam's size, shape, and grade, as well as the span and support conditions of the particular application. Steel H-beams are specifically engineered to endure substantial loads, making them prevalent in construction and structural engineering endeavors. To ascertain the precise maximum load capacity for a particular steel H-beam, it is imperative to seek advice from engineering experts or consult structural design guidelines and load tables supplied by manufacturers.

- Q: Can steel H-beams be used for hospitals?

- Yes, steel H-beams can be used for hospitals. Steel H-beams are commonly used in construction projects, including hospitals, due to their strength, durability, and ability to support heavy loads. They provide structural integrity and can be used for various applications such as framing, support columns, and beams in hospital buildings.

- Q: How do steel H-beams perform in extreme weather conditions?

- Steel H-beams are known for their excellent performance in extreme weather conditions. Due to their high strength and durability, they can withstand extreme temperatures, heavy snow loads, strong winds, and even earthquakes. Additionally, steel H-beams are resistant to corrosion, ensuring their longevity and reliability in various weather conditions.

- Q: Can steel H-beams be used in the construction of automotive showrooms or dealerships?

- Yes, steel H-beams can be used in the construction of automotive showrooms or dealerships. Steel H-beams are commonly used in commercial construction due to their strength and durability. They can provide structural support for large open spaces, allowing for flexible and spacious showroom designs. Additionally, steel H-beams can withstand heavy loads, making them suitable for displaying cars and other vehicles in dealerships.

- Q: What are the different grades of steel used for manufacturing H-beams?

- There are several grades of steel that are commonly used for manufacturing H-beams. These grades vary in terms of their chemical composition and mechanical properties, which determine their suitability for different applications. Some of the commonly used grades include: 1. ASTM A36: This is a low carbon steel grade that is widely used for general structural purposes. It offers excellent weldability and machinability, making it a popular choice for H-beam manufacturing. 2. ASTM A572: This grade of steel offers higher strength and better corrosion resistance compared to A36. It is commonly used for applications that require higher load-bearing capacity, such as in heavy construction and bridge building. 3. ASTM A992: This grade is specifically designed for wide-flange shapes like H-beams. It offers higher yield strength and better ductility compared to A36, making it suitable for structural applications that require superior performance. 4. ASTM A588: This grade of steel is known for its high atmospheric corrosion resistance. It is often used in outdoor applications, such as bridges and buildings located in harsh environments. 5. ASTM A709: This grade is primarily used for construction of bridges and other infrastructure projects. It offers high tensile strength, excellent toughness, and improved weldability, making it suitable for H-beam manufacturing in such applications. It is important to note that the selection of a specific grade of steel depends on the requirements of the project, including the load-bearing capacity, environmental conditions, and other factors. Consulting with a structural engineer or steel supplier can help determine the most appropriate grade for a particular application.

- Q: Can steel H-beams be used in railway platforms?

- Yes, steel H-beams can be used in railway platforms. They are commonly used due to their strength, durability, and ability to support heavy loads, making them suitable for railway infrastructure.

- Q: Are steel H-beams resistant to earthquakes?

- Due to their strength and structural integrity, steel H-beams are commonly used in construction. They have been proven to be highly resistant to earthquakes. The H-beam's unique shape provides excellent load-bearing capacity and stability, making it a reliable choice for areas prone to earthquakes. One reason why steel H-beams resist earthquakes is their ability to flex without breaking. During an earthquake, the ground shakes and moves in different directions. The flexibility of steel H-beams allows them to absorb and distribute the seismic energy, enabling them to withstand the lateral forces produced by the earthquake. This flexibility prevents the beams from fracturing or collapsing under the intense stress. Furthermore, steel H-beams are renowned for their ductility, meaning they can deform without losing their strength. This quality is particularly important during seismic events. As the ground shakes, the H-beams can flex and bend, absorbing the energy and reducing the impact on the overall structure. This ductility ensures that the beams can withstand the dynamic forces of an earthquake while maintaining their structural integrity. Additionally, steel H-beams possess high tensile strength, allowing them to withstand significant tension. This is crucial during an earthquake when the ground movements can create tension forces within the building. The strong tensile strength of the H-beams enables them to resist these forces and prevent structural failure. In conclusion, steel H-beams are indeed resistant to earthquakes. Their flexibility, ductility, and high tensile strength enable them to withstand the lateral and dynamic forces generated by seismic events. By incorporating steel H-beams into construction designs, engineers can enhance the seismic resistance of buildings and ensure the safety of occupants during earthquakes.

- Q: Can steel H-beams be used in airport or terminal construction?

- Yes, steel H-beams can be used in airport or terminal construction. They are commonly utilized in the construction of large structures like airports or terminals due to their high strength, versatility, and ability to support heavy loads. The H-beams provide structural stability and are often used for framing, columns, or support beams in the construction of these buildings.

- Q: Can steel H-beams be used in parking garage construction?

- Indeed, parking garage construction can make use of steel H-beams. In the construction industry, steel H-beams are widely employed owing to their robustness, longevity, and capacity to endure substantial loads. Structural elements in parking garages must be capable of sustaining the weight of numerous vehicles while enduring diverse environmental conditions. Consequently, steel H-beams possess these essential qualities, rendering them an appropriate selection for parking garage construction. Furthermore, their adaptability permits flexible design possibilities, thereby facilitating the creation of efficient and secure parking structures.

Send your message to us

Hot Rolled Structural Steel H-beam JIS Standard all Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords