Hot Rolled Steel Sheets SS400 Steel Plates Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

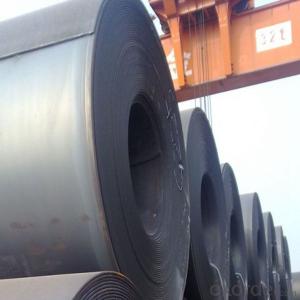

DETAILED PICTURES FOR STEEL COILS

EXPORT MARKET FOR STEEL COILS/SHEETS

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: Can steel sheets be used for electrical transformer cores?

- Yes, steel sheets can be used for electrical transformer cores. Steel is a common material used for transformer cores due to its magnetic properties and ability to efficiently transfer and distribute electrical energy. The laminated core design of stacked steel sheets reduces energy losses through eddy currents and helps in transforming voltage levels effectively.

- Q: What is the bending radius for steel sheets?

- The bending radius for steel sheets can vary depending on the thickness and type of steel being used. In general, a minimum bending radius of 1.5 times the thickness of the steel sheet is often recommended. However, it is always best to consult the specific guidelines or recommendations provided by the steel manufacturer for accurate bending radius information.

- Q: What are the common sizes of steel sheets available?

- To meet the diverse needs of different industries and applications, a variety of sizes of steel sheets are available. The sizes of steel sheets can vary depending on the manufacturer and the specific requirements of the customer. However, there are standard sizes widely available in the market. The most popular sizes of steel sheets are as follows: 1. 4 feet by 8 feet: This size is widely used in construction, manufacturing, and automotive industries. It is suitable for various applications like roofing, siding, and fabrication due to its large surface area. 2. 4 feet by 10 feet: Similar to the 4 feet by 8 feet sheets, this size provides a larger surface area. It is ideal for bigger projects that require more material. 3. 5 feet by 10 feet: With an even larger surface area than the 4 feet by 10 feet sheets, this size is perfect for industrial applications that need extensive coverage. 4. 6 feet by 12 feet: This larger size is commonly used in heavy-duty applications such as shipbuilding, construction of large structures, and industrial machinery. It's important to acknowledge that these are just some of the common sizes available. Manufacturers offer many other sizes to meet specific requirements. Moreover, steel sheets can be custom-cut to fit specific dimensions, allowing for greater flexibility and tailoring to individual project needs.

- Q: Are steel sheets suitable for railway infrastructure?

- Yes, steel sheets are suitable for railway infrastructure due to their high strength, durability, and resistance to wear and tear. Steel sheets are often used for railway track components such as rails, sleepers, and bridges, as they can withstand heavy loads and provide stability to the railway system. Additionally, steel sheets can be easily fabricated and maintained, making them an ideal choice for railway construction projects.

- Q: What are the common industries that use steel sheets?

- The common industries that use steel sheets include construction, automotive, aerospace, manufacturing, and appliance industries.

- Q: Are steel sheets resistant to impact or damage?

- Steel sheets possess remarkable strength and durability, attributes that render them exceptionally resistant to impact and damage. Their robust tensile strength enables them to endure substantial loads and withstand external forces without deformation or breakage. Thus, they find extensive use in critical applications that demand impact resistance, such as construction, automotive manufacturing, and industrial settings. Furthermore, steel sheets exhibit exceptional resilience against extreme temperatures, corrosion, and environmental factors, further enhancing their overall resistance to damage. However, it is worth noting that the degree of impact or damage resistance may vary depending on the thickness, quality, and composition of the steel sheet.

- Q: Are the steel sheets suitable for agricultural applications?

- Yes, steel sheets are suitable for agricultural applications. Steel is a versatile and durable material that can withstand harsh weather conditions and provide long-term structural support. Steel sheets can be used in various agricultural applications such as constructing farm buildings, barns, sheds, and storage facilities. They can also be used for fencing, roofing, and siding purposes. Steel sheets offer excellent strength and resistance to pests, fire, and rot, making them ideal for protecting agricultural equipment and crops. Additionally, steel is recyclable, which makes it an environmentally-friendly choice for sustainable farming practices. Overall, steel sheets are a reliable and cost-effective solution for various agricultural applications.

- Q: What is the typical coefficient of thermal expansion of a steel sheet?

- Steel sheets typically have a coefficient of thermal expansion of approximately 10-12 ppm/°C. This signifies that for every degree Celsius rise in temperature, the steel sheet will expand uniformly in all directions by 10-12 ppm. However, it is crucial to acknowledge that the coefficient of thermal expansion may differ based on the precise type and composition of the steel. Various steel alloys may exhibit slightly varied coefficients, although the range of 10-12 ppm/°C is widely accepted as the average.

- Q: How do you prevent galvanic corrosion when using steel sheets with other metals?

- One way to prevent galvanic corrosion when using steel sheets with other metals is by applying a protective coating or barrier between the metals. This can be done through methods such as painting, powder coating, or using a corrosion-resistant primer. Additionally, using non-conductive materials or insulating the metals from direct contact can also help prevent galvanic corrosion. Regular maintenance and inspection to identify any signs of corrosion early on is also important in preventing its progression.

- Q: Is galvanized steel plate fire-resistant?

- Galvanized steel is mainly antiseptic, and he has no fire protection

Send your message to us

Hot Rolled Steel Sheets SS400 Steel Plates Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords