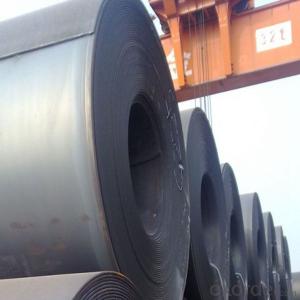

Hot Rolled Steel Sheets SS400 Hot Rolled Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

EXPORT MARKET FOR STEEL COILS/SHEETS

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: Can steel sheets be used in food processing or pharmaceutical industries?

- Steel sheets are indeed applicable for use in the food processing and pharmaceutical industries. These industries often utilize stainless steel sheets because of their remarkable resistance to corrosion, their durability, and their hygienic properties. Stainless steel, known for being non-reactive and not releasing any harmful substances into food or pharmaceutical products, is frequently employed. Furthermore, its ease of cleaning and maintenance makes it a suitable option for applications that necessitate high levels of cleanliness and hygiene. Moreover, stainless steel sheets are capable of withstanding extreme temperatures and are resistant to impact and abrasion, making them an ideal choice for the food processing and pharmaceutical industries, where stringent quality and safety standards are crucial.

- Q: How do you cut a steel sheet?

- To cut a steel sheet, you will need to use the appropriate tools and techniques. Here are a few common methods: 1. Power tools: The most common power tool used for cutting steel sheets is an angle grinder equipped with a cutting disc. Make sure to wear safety goggles and gloves while operating the grinder. Mark the cutting line on the sheet using a marker or chalk, then slowly and steadily guide the grinder along the marked line to cut through the steel. 2. Shears: If you are cutting a thin steel sheet, you can use manual or electric shears. These tools have a scissor-like cutting mechanism specifically designed for cutting metal. Place the steel sheet between the blades of the shears, aligning the cutting line with the blades, and apply steady pressure to cut through the sheet. 3. Plasma cutting: This method is best suited for thicker steel sheets. Plasma cutting involves using a high-velocity jet of ionized gas (plasma) to melt and sever the metal. It requires specialized equipment, such as a plasma cutter, which uses an electric arc to create the plasma jet. 4. Waterjet cutting: Another effective method for cutting steel sheets is waterjet cutting. It uses a high-pressure jet of water mixed with an abrasive substance (such as garnet) to cut through the metal. This technique is ideal for complex shapes and precise cuts, but it requires specialized machinery. Before attempting to cut a steel sheet, always prioritize safety. Wear appropriate protective gear, such as safety glasses, gloves, and a face shield if necessary. Additionally, ensure that you are working in a well-ventilated area to avoid inhaling any fumes or particles generated during the cutting process.

- Q: Are the steel sheets resistant to graffiti or vandalism?

- Yes, steel sheets are typically resistant to graffiti and vandalism due to their durable and non-porous surface, making it difficult for paint or markers to adhere to them.

- Q: What is the difference between a galvanized and aluminized steel sheet?

- The durability and corrosion-resistant properties of galvanized steel and aluminized steel sheets make them widely used in various industries. However, there are notable distinctions between the two. Galvanized steel sheets have a layer of zinc coating that safeguards the underlying steel from rust and corrosion. This process, called galvanization, can be accomplished by immersing the steel sheet in a bath of molten zinc or by electroplating a zinc-rich coating. The zinc layer acts as a sacrificial barrier, meaning it will corrode before the steel, providing excellent rust protection. Galvanized steel finds common usage in outdoor applications like roofing, fences, and automobile parts. In contrast, aluminized steel sheets are coated with an aluminum-silicon alloy layer. This process, known as aluminization, involves immersing the steel sheet in a bath of molten aluminum or applying a thin layer of aluminum-silicon alloy through a continuous hot-dip process. The aluminum-silicon coating offers remarkable heat resistance and corrosion resistance. Aluminized steel is commonly employed in applications where high temperatures are present, such as automotive exhaust systems, heat exchangers, and ovens. To summarize, the primary distinction between galvanized and aluminized steel sheets lies in the type of coating applied to the steel. Galvanized steel is coated with zinc, providing outstanding rust protection, while aluminized steel is coated with an aluminum-silicon alloy, offering superior heat and corrosion resistance. The choice between the two depends on the specific requirements of the application, such as the presence of high temperatures or the need for long-lasting rust protection.

- Q: Are steel sheets resistant to impact and vibration?

- Yes, steel sheets are generally resistant to impact and vibration due to their strong and sturdy nature.

- Q: Can steel sheets be used for elevator cabins?

- Yes, steel sheets can be used for elevator cabins. Steel is a common material choice for elevator cabins due to its strength, durability, and fire resistance properties. Steel sheets can be fabricated to create a sleek and modern look for elevator cabins, and they can also be easily customized to fit specific design requirements. Additionally, steel is a cost-effective option for elevator cabins as it is readily available and has a long lifespan.

- Q: What are the different certification standards for steel sheets?

- There are several certification standards that exist for steel sheets, each with their own specific requirements and criteria. Some of the most commonly recognized certification standards for steel sheets include: 1. ASTM International: ASTM A1008/A1008M is a standard specification for cold-rolled, carbon steel sheets. This certification standard ensures that the steel sheets meet specific mechanical properties, chemical composition, and dimensional requirements. 2. American Society of Mechanical Engineers (ASME): ASME SA240 is a specification for chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and general applications. This certification standard ensures the quality and safety of stainless steel sheets used in various industrial applications. 3. International Organization for Standardization (ISO): ISO 3574 is a standard specification for cold-reduced carbon steel sheet of commercial and drawing qualities. ISO 3574 certification ensures that the steel sheets have specific mechanical properties, surface finish, and dimensions. 4. European Committee for Standardization (CEN): EN 10025 is a European standard for hot-rolled structural steel products. This certification standard covers various grades and dimensions of steel sheets used in construction and engineering applications. 5. Japanese Industrial Standards (JIS): JIS G 3141 is a Japanese standard for cold-reduced carbon steel sheets and strips. This certification standard ensures that the steel sheets meet specific mechanical properties, chemical composition, and dimensional requirements. These are just a few examples of the certification standards available for steel sheets. Depending on the intended application and geographical location, there may be additional regional or industry-specific certification standards that need to be met to ensure the quality and suitability of the steel sheets.

- Q: Can steel sheets be used for manufacturing musical instruments?

- Yes, steel sheets can be used for manufacturing certain musical instruments, such as steel drums, tambourines, or some types of percussion instruments. However, they are not commonly used for traditional instruments like guitars, pianos, or brass instruments. The choice of materials for musical instrument manufacturing depends on the desired sound, resonance, and specific requirements of each instrument.

- Q: What is the average price of a steel sheet?

- Several factors, including size, thickness, quality, and market conditions, can cause the average price of a steel sheet to fluctuate. Typically, steel sheets can be priced anywhere from $500 to $1500 per ton. Nevertheless, it's crucial to bear in mind that prices may vary due to global demand, production costs, and trade policies. Moreover, various suppliers may present different price points, making it wise to compare prices from multiple sources prior to making a purchase decision.

- Q: Can steel sheets be used in food processing or medical applications?

- Yes, steel sheets can be used in food processing or medical applications. Stainless steel, in particular, is commonly used due to its corrosion resistance, durability, and ease of cleaning. It meets the stringent hygienic requirements of food processing and medical industries.

Send your message to us

Hot Rolled Steel Sheets SS400 Hot Rolled Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords